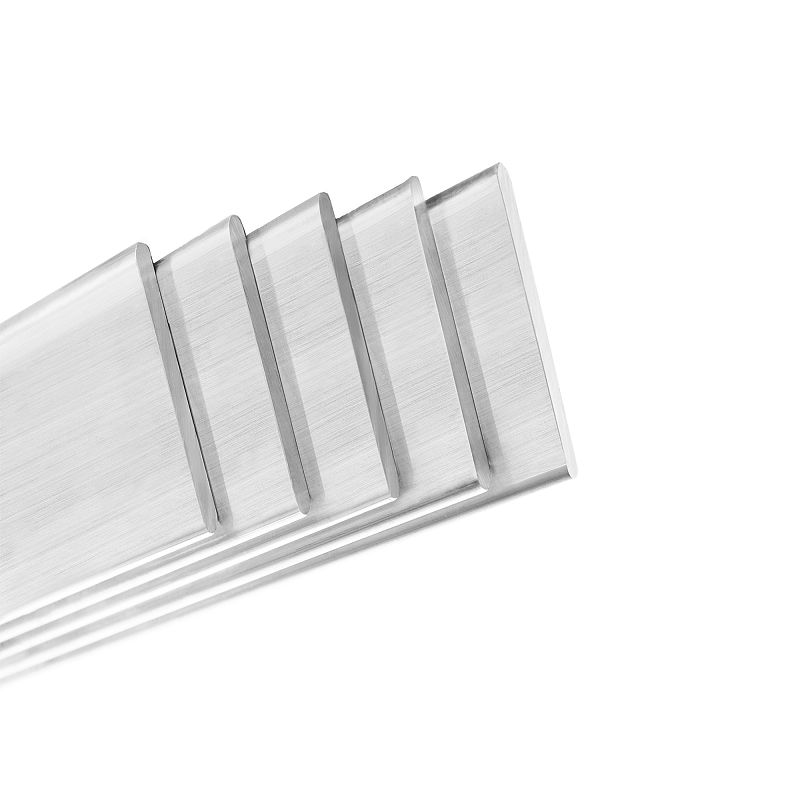

High-Quality Aluminum Busbar for Efficient Electrical Distribution

Product Description

Aluminum busbars are conductive materials designed specifically for power distribution and connection, and are usually composed of aluminum alloys. Its unique properties make it ideal for a variety of applications, especially power systems, substations and industrial equipment.

One of the most significant advantages of aluminum busbars is their lightweight nature. This feature not only facilitates easier handling and installation, but also reduces the overall structural load on the supporting frame. In environments where weight is a key factor, such as high-rise buildings or mobile equipment, aluminum busbars provide a practical solution. Additionally, their good electrical conductivity ensures efficient power transmission, making them a reliable choice for electrical engineers and designers.

When comparing aluminum busbars to copper busbars, several factors come into play. While copper busbars are known for their superior electrical conductivity, aluminum busbars offer a more cost-effective alternative. Aluminum’s lower material cost makes it an attractive option for larger projects on a budget. Additionally, aluminum has better corrosion resistance than copper, which is especially beneficial in environments exposed to moisture or corrosive elements. This durability extends the life of the busbars and reduces the need for frequent replacement and maintenance.

The conductivity difference between aluminum and copper must be taken into account when designing electrical systems. Aluminum busbars have lower electrical conductivity and require a larger cross-sectional area to achieve the same load capacity as copper busbars. Engineers must carefully size aluminum busbars to ensure they can handle the required electrical load without overheating or causing inefficiencies. This design consideration is critical to maintaining the safety and reliability of the power distribution system.

In terms of installation and maintenance, the use of aluminum busbars is relatively simple. Their lightweight nature simplifies the installation process, allowing for faster assembly and lower labor costs. Additionally, aluminum busbars have lower maintenance requirements compared to other materials because they are less susceptible to corrosion and degradation. This ease of maintenance is particularly beneficial in industrial environments, where downtime can result in significant financial losses. Overall, aluminum busbars represent a practical and efficient solution for large-scale power transmission and distribution, combining cost-effectiveness with reliable performance.

Aluminum busbars play a vital role in modern electrical systems and offer a range of advantages that make them suitable for a variety of applications. Its lightweight design, cost advantages and corrosion resistance make it the first choice for power distribution in substations and industrial equipment. Although its conductivity and load capacity need to be carefully considered during the design phase, the overall advantages of aluminum busbars make it an important part of the electrical engineering field.