Everything You Need to Know About Joints: Types, Functions, and Common

Product Description

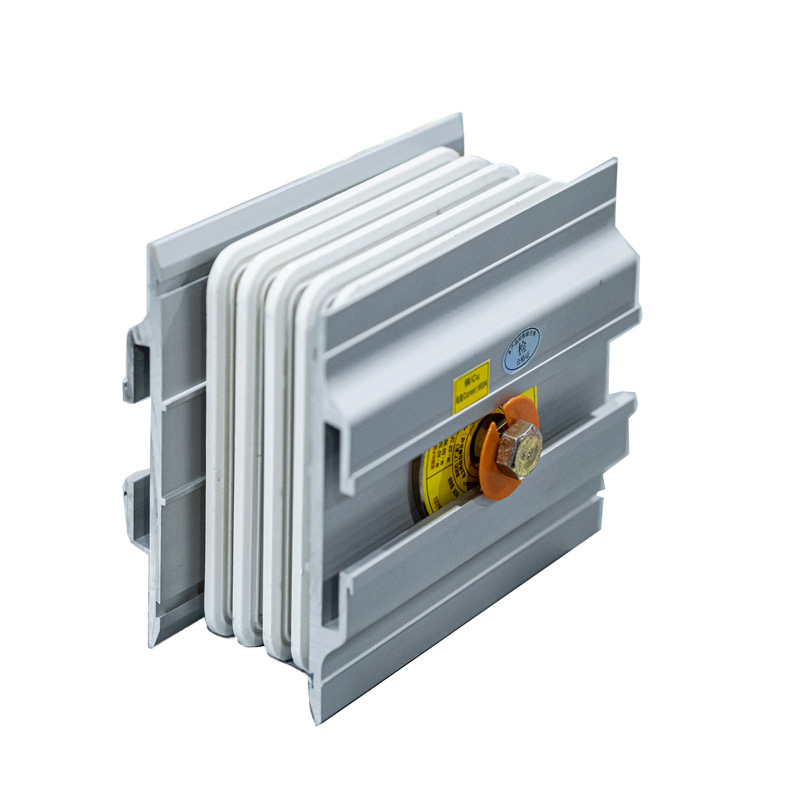

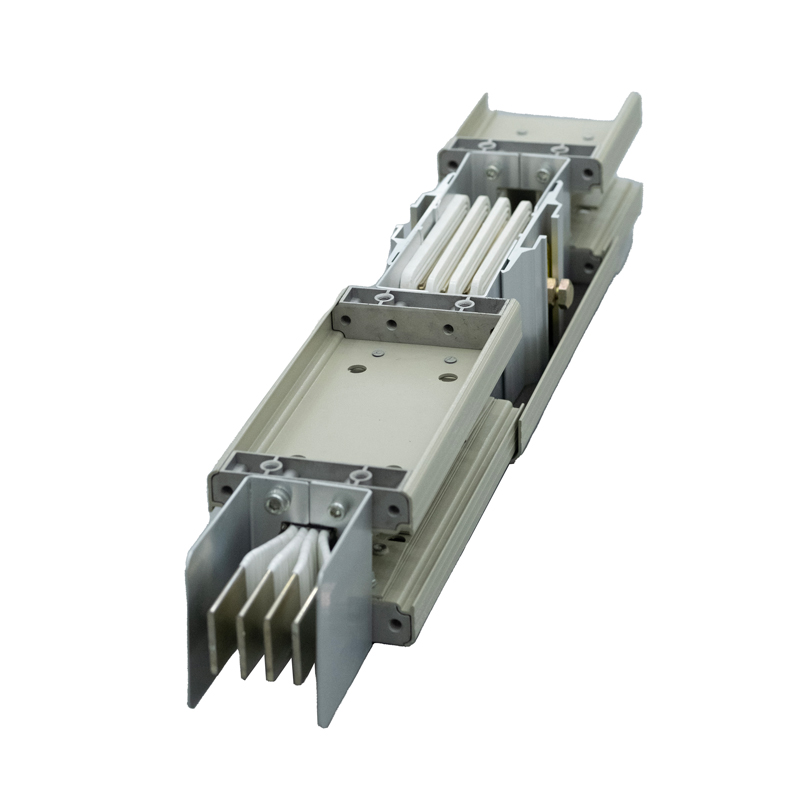

The system is designed to safely transmit electricity from a substation or distribution room to various electrical consumers through a series of conductive busbars and connections. While the overall design of the busway is critical, the importance of the busway joints cannot be overstated. These connectors are critical to the system, ensuring electrical connectivity and mechanical stability.

The busway joint is an integral component that promotes seamless connection between different sections of the busbar. They are designed not just for convenience; It is a key factor affecting the overall performance of the power busway system. High-quality connectors are engineered to minimize contact resistance, which is critical to maintaining optimal conductivity. When resistance is minimized, the risk of overheating and subsequent failure is significantly reduced. This is especially important in high-current applications, where even small inefficiencies can lead to large power losses and potential safety hazards.

The mechanical stability provided by the busway joints is equally important. These joints must withstand a variety of stresses, including thermal expansion, vibration and mechanical loading. The robust connector design ensures that the busbars remain securely connected, preventing any disconnections that could cause system failure. The reliability of the entire distribution system depends on the integrity of these joints, which makes them a focal point in the design and implementation of busway systems.

In addition to their functional role, busway joints contribute to the overall safety of the electrical busway system. High-quality connectors play a vital role in protecting equipment and personnel by effectively managing heat dissipation and minimizing the risk of electrical failure. The design of these joints often includes features that enhance their thermal management capabilities, ensuring that they operate efficiently even under high load conditions. In industrial and commercial environments, attention to safety and reliability is critical, as the consequences of electrical failures can be severe.

The importance of busway joints in power busway systems cannot be ignored. They are an important component in ensuring efficient and safe power transmission. High-quality busway connectors help improve the overall efficiency of the power distribution system by minimizing contact resistance, providing mechanical stability, and enhancing safety.