Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

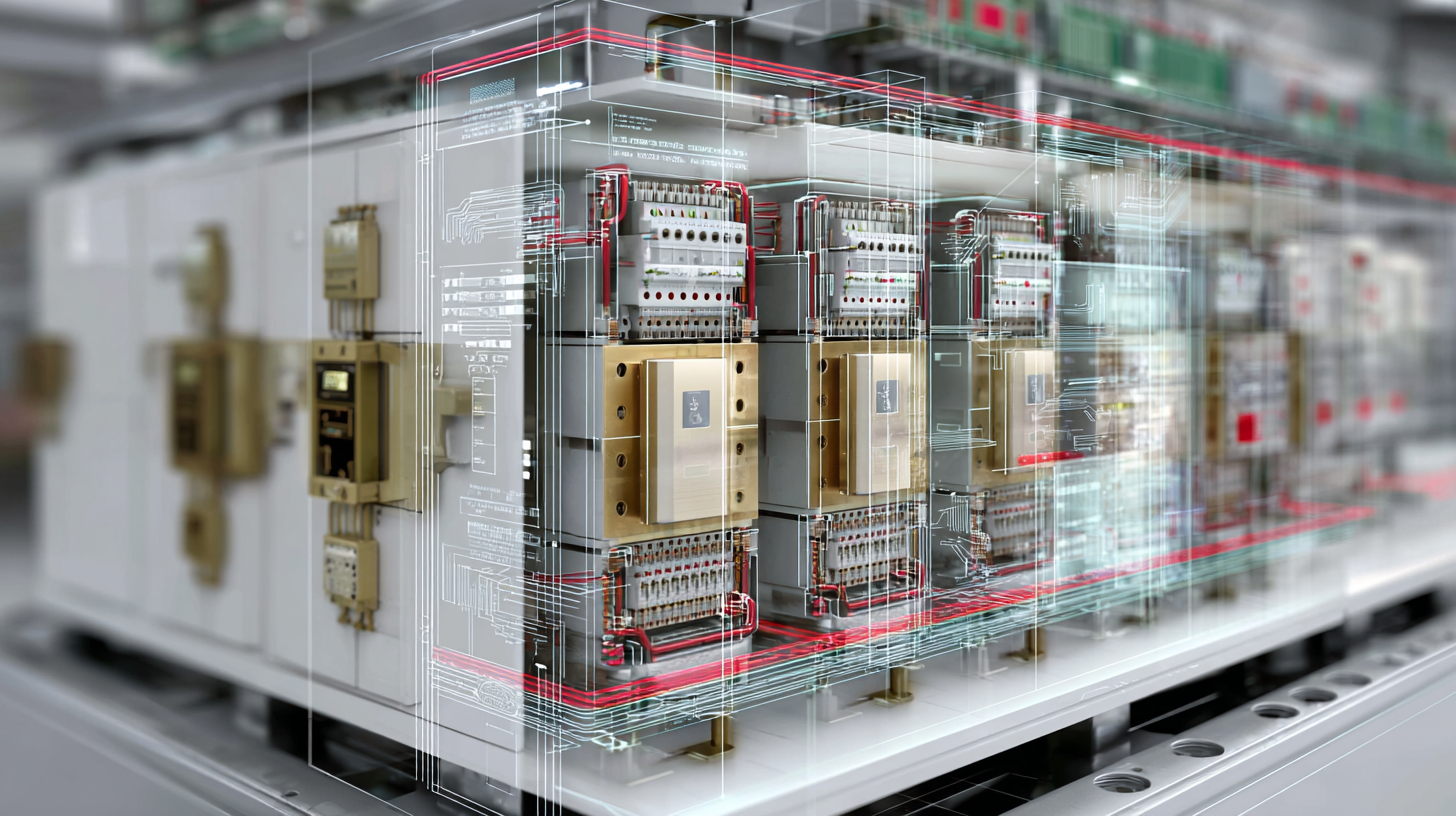

The global busbar busduct market has seen significant growth, driven by the escalating demand for energy-efficient solutions in industrial and commercial sectors. According to a recent report by MarketsandMarkets, the busbar busduct market is projected to reach USD 6.19 billion by 2025, growing at a CAGR of 5.2% during the forecast period. This surge emphasizes the importance of sourcing from reliable manufacturers who adhere to stringent quality standards.

In an industry where safety and efficiency are paramount, selecting the right busbar busduct supplier becomes crucial for ensuring optimal performance and durability of electrical systems. This blog aims to unlock proven strategies for identifying quality manufacturers, empowering businesses to make informed decisions and secure superior products that meet their operational needs.

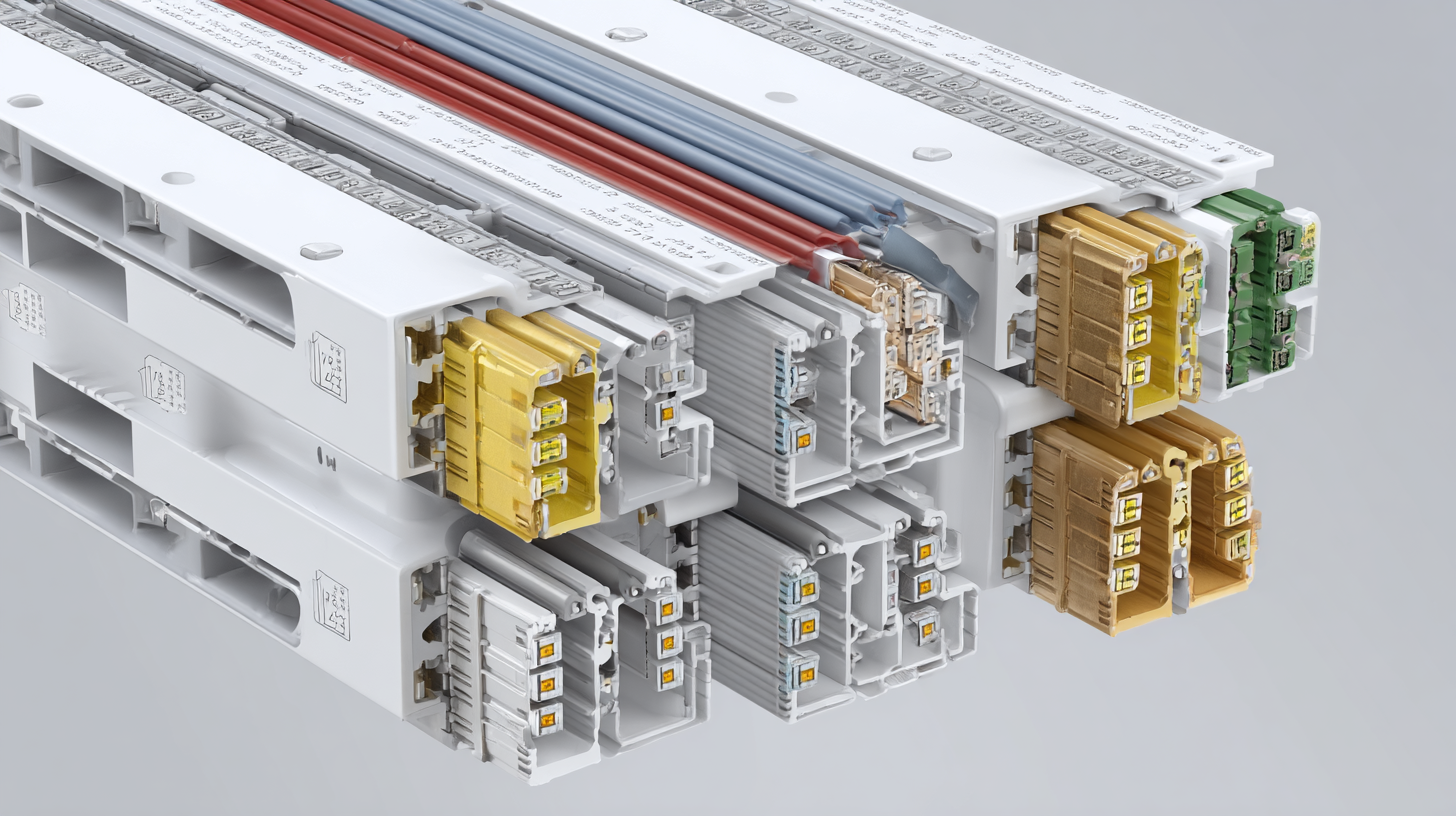

When selecting busbar busduct manufacturers, it's essential to identify the key criteria that align with your project's requirements. As the global bus duct market is projected to grow significantly in the coming years, understanding what to look for in suppliers can help in sourcing high-quality products. Focus on suppliers that demonstrate proven expertise in material quality and innovation, as these factors are critical for ensuring reliability in power distribution applications.

Tip: Evaluate Supplier Experience

Look for manufacturers with a strong track record in the industry. Experience not only enhances a supplier's expertise but also reflects their capability to meet diverse project demands. Suppliers with established reputations can offer insights and solutions that potentially lead to improved efficiency and safety.

Tip: Assess Technological Advancements

Investing in suppliers who utilize cutting-edge technologies is crucial. Nowadays, manufacturers employing advanced methods, such as temperature rise testing and thermal degradation monitoring systems, are more likely to deliver reliable and safe busduct solutions. These innovations can significantly reduce risks associated with overheating and ensure long-term operational efficacy.

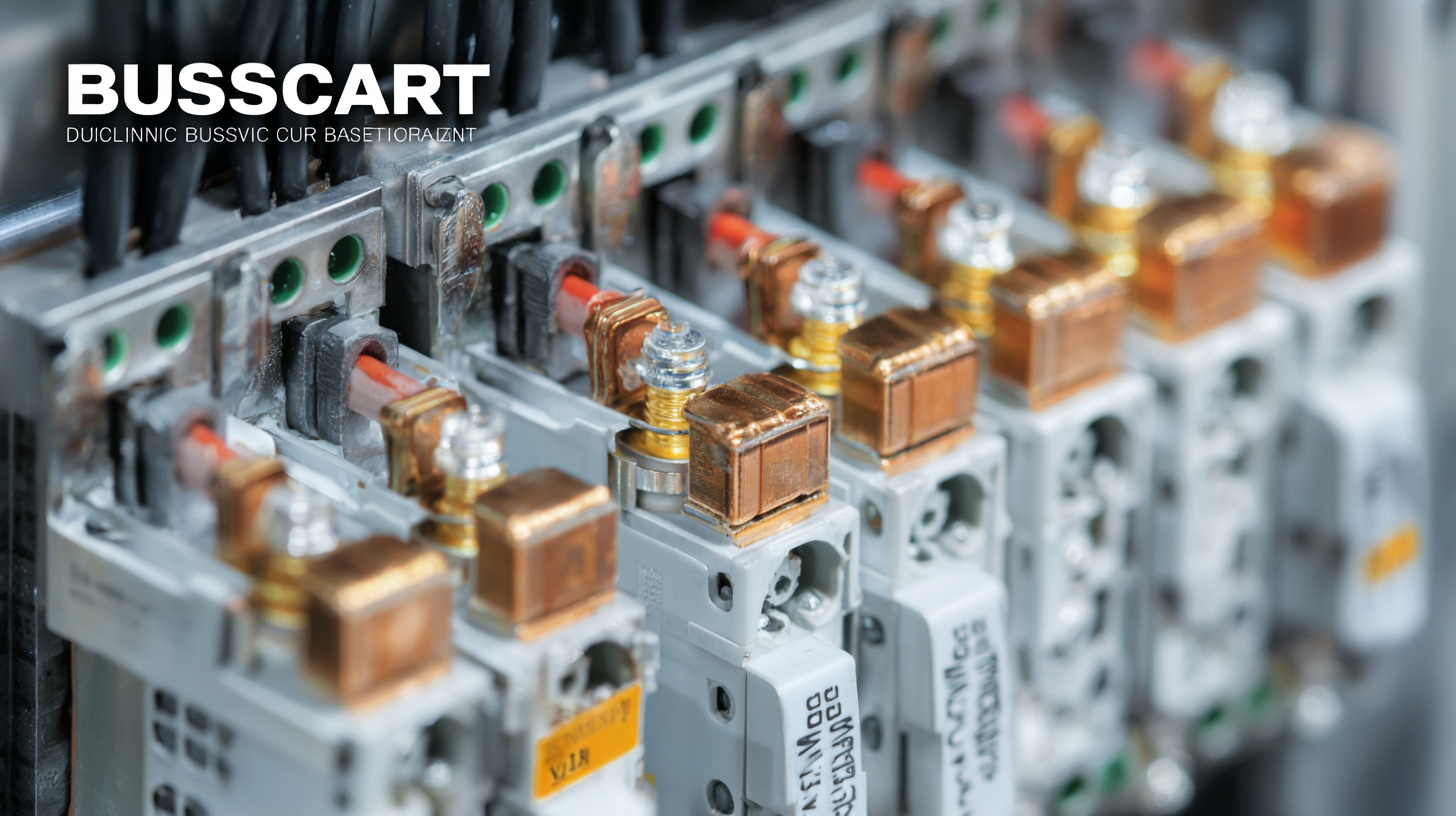

When sourcing busbar busduct suppliers, evaluating supplier reputation and industry experience is crucial for ensuring high-quality products and reliable service. A supplier’s reputation can often be gauged through customer reviews, testimonials, and industry certifications. Engaging with previous clients and examining case studies can provide insights into the supplier's reliability, product performance, and customer service. Recognizing suppliers with a strong track record can significantly mitigate the risks associated with poor product quality or unsatisfactory support.

Industry experience plays an equally vital role in supplier selection. Suppliers that have been established for many years typically possess extensive technical knowledge and a well-developed understanding of market dynamics. Look for suppliers who have successfully completed various projects, preferably within your specific sector. Their ability to adapt to changing requirements and their familiarity with industry standards reflect their commitment to quality and innovation. By prioritizing suppliers with solid reputations and substantial experience, businesses can enhance their procurement strategies and achieve long-term success in sourcing quality busbar busduct solutions.

When it comes to sourcing high-quality busbars and busducts, understanding quality assurance standards in production is crucial. These standards ensure that products meet specific performance and safety criteria, ultimately affecting reliability and customer satisfaction. International standards such as ISO 9001 provide a framework for manufacturers to enhance their processes, ensuring consistent quality throughout production.

Tip: Always check if the supplier is certified to quality management systems. A dependable supplier should have up-to-date certifications and a documented track record of compliance with recognized standards.

Additionally, consider the materials used in busbar production. High-grade materials, like copper and aluminum, not only guarantee better conductivity but also improve long-term durability. Ensuring that suppliers adhere to strict material specifications is essential for achieving optimal performance.

Tip: Request detailed material specifications and test certificates from suppliers. This information can give insights into their commitment to quality and help you make informed sourcing decisions.

In the competitive landscape of sourcing busbar busduct suppliers, ensuring supply chain transparency and reliability is paramount. A transparent supply chain not only allows companies to track the origin and quality of materials but also builds trust with stakeholders. By establishing clear communication channels and implementing robust tracking systems, businesses can gain insights into their suppliers’ practices. This visibility enables organizations to make informed decisions, ensuring they partner with suppliers who adhere to ethical standards and deliver high-quality products consistently.

Moreover, reliability in the supply chain is crucial for maintaining operational efficiency. Companies must assess suppliers based on their track record and ability to meet delivery timelines. Conducting thorough audits and fostering long-term relationships with reliable suppliers can significantly enhance operational resilience. By prioritizing suppliers who demonstrate a commitment to transparency and reliability, businesses can reduce risks associated with disruptions, ultimately leading to improved performance and customer satisfaction in the marketplace.

When selecting busbar busduct suppliers worldwide, evaluating customer support and after-sales services is crucial for ensuring long-term partnerships and reliable product performance. A supplier's commitment to addressing customer inquiries promptly often reflects their overall service quality. Consider how quickly they respond to your initial contact—ideally, within 24 hours. Efficient communication can save valuable time and resources, especially in urgent situations.

Tips for identifying supportive suppliers include assessing their availability for technical assistance and whether they offer training courses for installation and maintenance. A reputable supplier should provide comprehensive documentation along with their products, including manuals and troubleshooting guides. Additionally, inquire about their warranty policies and how they handle product returns or defects. Understanding these aspects can prevent future headaches and ensure you have a reliable partner for all your busduct needs.

To further evaluate after-sales support, look into customer testimonials and case studies. A company with a strong track record of customer satisfaction often demonstrates their ability to resolve issues effectively. Request references from current clients and ask about their experiences with the supplier's support team. By taking these steps, you can confidently partner with suppliers who prioritize your needs and guarantee quality service.