Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

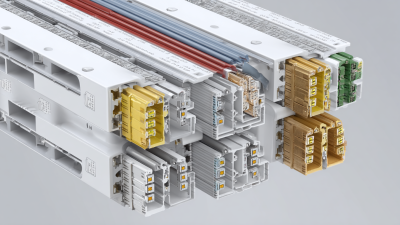

In the realm of electrical distribution systems, efficiency and reliability are paramount, making the selection of appropriate components crucial. Among these, the Cast Resin Busbar stands out as an innovative solution designed to enhance electrical performance while ensuring safety. This guide aims to demystify the intricacies of Cast Resin Busbars, exploring their construction, advantages, and applications in modern power distribution systems. With their exceptional dielectric properties and resilience against environmental factors, Cast Resin Busbars not only optimize electrical flow but also significantly reduce maintenance costs. As industries increasingly prioritize sustainability and efficiency, understanding the role of Cast Resin Busbars becomes essential for engineers and decision-makers alike. Join us as we delve into this comprehensive tutorial, equipping you with the knowledge to integrate Cast Resin Busbars effectively into your electrical distribution strategies.

When examining the differences between cast resin busbars and traditional busbars, it's essential to highlight both their physical properties and performance characteristics.

Cast resin busbars, commonly encased in a composite material, offer superior insulation and protection against environmental factors such as moisture, dust, and corrosion. This results in a longer operational lifespan and reduced maintenance needs compared to traditional metal busbars, which may be more susceptible to oxidation and require periodic servicing.

Cast resin busbars, commonly encased in a composite material, offer superior insulation and protection against environmental factors such as moisture, dust, and corrosion. This results in a longer operational lifespan and reduced maintenance needs compared to traditional metal busbars, which may be more susceptible to oxidation and require periodic servicing.

Moreover, the thermal performance of cast resin busbars is often more efficient. Their design allows for better heat dissipation, minimizing the risk of overheating during peak loads. This efficiency not only enhances performance but also contributes to overall energy savings in electrical distribution systems.

Additionally, the installation of cast resin busbars is typically more straightforward and less labor-intensive. In contrast, traditional busbars may require complex support structures and additional safety measures due to their exposed metal components. This comparative analysis highlights how cast resin busbars present a modern solution for reliable and efficient electrical distribution, positioning them as a preferable choice for contemporary installations.

Cast resin busbars are increasingly recognized for their effectiveness in electrical distribution systems. One of the primary advantages of these busbars is their excellent insulation properties. The resin encapsulation protects against environmental factors such as moisture, dust, and corrosive substances, leading to improved durability and reliability. Additionally, cast resin busbars can be manufactured in compact designs, allowing for space-efficient installations while ensuring effective power distribution.

However, there are limitations to consider. The initial cost of cast resin busbars can be higher compared to traditional alternatives. This upfront investment may deter some organizations, particularly those with tight budgets. Moreover, while they offer superior insulation, repair and maintenance can be more challenging, as any damage to the resin may necessitate complete replacement rather than localized repairs.

**Tip 1:** When considering cast resin busbars, evaluate your environment closely; if you're in a high-humidity or corrosive setting, the benefits may outweigh initial costs.

**Tip 2:** Always consult with electrical engineers to ensure that the specific requirements of your system align with the advantages of cast resin busbars to maximize efficiency and longevity.

| Dimension | Description | Advantages | Limitations |

|---|---|---|---|

| Material Composition | Cast resin, usually based on epoxy or polyester. | High resistance to environmental factors such as moisture and pollution. | Higher initial cost compared to traditional busbars. |

| Thermal Performance | Ability to maintain performance under high temperatures. | Excellent thermal conductivity, enhancing heat dissipation. | Potential for thermal expansion causing mechanical stress. |

| Electrical Insulation | Highly effective electrical insulation properties. | Reduces risk of electrical faults and improves safety. | Cannot be repaired easily once damaged. |

| Weight | Typically lighter than metal busbars. | Easier to install and handle during installation. | May require additional support depending on design. |

| Durability | Resistant to corrosion and environmental damage. | Long service life minimizes replacement needs. | Limited resistance to mechanical impacts. |

When it comes to the cost-effectiveness of electrical distribution systems, cast resin busbars stand out compared to traditional busbar types such as copper or aluminum. According to a report by the International Electrotechnical Commission (IEC), the lifecycle cost of cast resin busbars can be up to 30% lower than that of copper busbars, primarily due to their reduced maintenance requirements and enhanced durability. Cast resin technology minimizes wear and tear on components, significantly lowering the total cost of ownership over time.

Additionally, a study by the American Council on Renewable Energy (ACORE) highlights that cast resin busbars offer superior insulation properties, which leads to increased energy efficiency. This efficiency translates into lower operational expenses, as less energy is wasted during distribution. Furthermore, their resistance to environmental factors means reduced susceptibility to degradation, thus ensuring long-term cost savings. For utilities looking to optimize performance while keeping budgets in check, cast resin busbars provide a compelling alternative to more traditional materials.

In the realm of electrical distribution systems, the choice of busbar materials significantly impacts performance metrics, particularly efficiency and reliability. Different materials exhibit distinct electrical properties, leading to varying levels of energy loss, thermal management, and overall functionality in applications such as electric vehicles (EVs) and renewable energy systems. For instance, materials with high conductivity ensure minimal energy loss, which is crucial for EV applications where every watt counts in prolonging battery range and performance.

Moreover, advancements in busbar technology, such as self-aligning and quick-connecting designs, are paving the way for enhanced reliability in applications. These innovations help eliminate potential hotspots, ensuring that connections remain stable even under rigorous conditions. The integration of modern materials in busbar designs not only enhances efficiency but also assists manufacturers in reducing warranty issues associated with traditional fastening methods. As the demand for energy-efficient solutions continues to rise, understanding the performance metrics associated with various busbar materials becomes essential for optimizing system performance and sustainability.

As the demand for more efficient electrical distribution systems grows, advancements in busbar technology are reshaping the landscape of power management. One significant trend is the increasing adoption of cast resin busbars, which offer superior insulation properties and resistance to environmental factors. Unlike traditional busbars, this innovative approach not only enhances operational reliability but also reduces maintenance costs over time. As industries transition towards greener technologies, cast resin busbars are poised to play a crucial role in powering renewable energy systems, thereby aligning with global sustainability initiatives.

Moreover, the integration of smart technologies within busbar systems is on the rise. With the incorporation of real-time monitoring and diagnostics, operators can gain valuable insights into performance metrics and potential issues, allowing for proactive maintenance and optimized energy distribution. This modernization not only improves efficiency but also enhances safety and mitigates risks. As we look to the future, the evolution of busbar technology, particularly the ongoing developments in cast resin configurations, will undoubtedly have a profound impact on how we manage and distribute electrical power across various sectors.