Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In today's rapidly evolving electrical infrastructure, the efficiency of power distribution systems is paramount. One of the integral components in achieving optimal electrical distribution is the Busbar End Feed Unit. According to Dr. John Smith, a leading expert in electrical engineering, "The Busbar End Feed Unit is crucial for ensuring a seamless connection and reliable power transfer in modern electrical systems." This statement highlights the significance of these units in facilitating effective energy distribution across various applications.

With energy demands increasing and the need for sustainable solutions becoming more pressing, the importance of selecting the right Busbar End Feed Unit cannot be overstated. These units not only enhance the reliability of power distribution but also improve operational efficiency and reduce potential downtime. As industries strive for greater efficiency, investing in high-quality Busbar End Feed Units becomes a strategic priority.

In this context, we will explore the top 10 Busbar End Feed Units that exemplify excellence in design and performance. Each unit will be evaluated based on its functionality, installation convenience, and adaptability to diverse applications, ensuring that businesses can make informed choices for their power distribution needs.

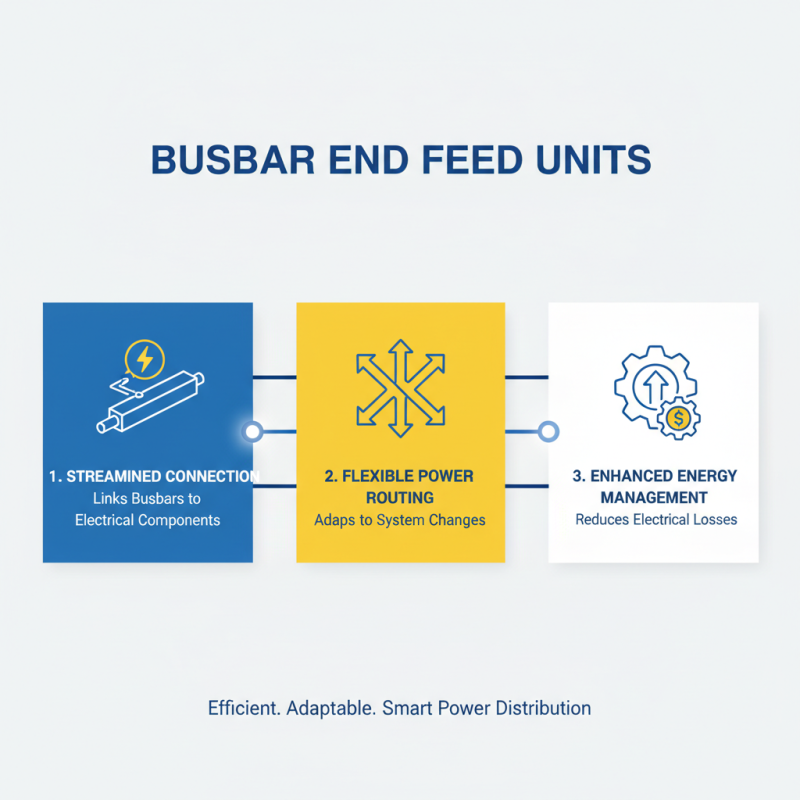

Busbar end feed units play a crucial role in modern electrical distribution systems. They provide a streamlined method for connecting busbars to various electrical components, ensuring efficient power distribution. These units allow for the flexible routing of electricity through adequate conductor sizes and configurations, which can accommodate changing system demands. By integrating these units, facilities can enhance their energy management while reducing potential electrical losses in transmission.

When selecting busbar end feed units, it's essential to consider factors like load capacity and environmental conditions. Ensuring that the units are compatible with the existing infrastructure can help avoid unnecessary complications and enhance overall performance. Regular maintenance checks are also advisable to identify wear and tear that could lead to inefficiencies.

Tips: Always verify that the connections are secure and free from corrosion. This simple step can prevent unexpected outages and extend the lifespan of your electrical distribution system. Additionally, consider future expansion when designing your electrical layout; modular systems can provide the flexibility needed to adapt to growing energy demands without extensive overhauls.

When selecting busbar end feed units for efficient electrical distribution, there are several key features that should be prioritized to ensure optimal performance and safety. One of the most critical elements is the current rating of the unit. It's essential to choose a busbar end feed unit that can handle the maximum load without overheating or causing failures. Additionally, the construction material plays a significant role; units made from high-conductivity materials, such as copper or aluminum, enhance efficiency by minimizing resistance and heat generation.

Another important consideration is the compatibility with various busbar systems. A versatile end feed unit should support a range of installations, whether for horizontal or vertical configurations. Furthermore, look for units that come with robust insulation and protective casing to prevent electrical hazards. Features such as easy installation interfaces and removable components can also simplify maintenance and upgrades, providing long-term reliability and adaptability in changing electrical environments.

When it comes to optimizing electrical distribution, selecting the right busbar end feed units is paramount. These units function as critical junctions, allowing for efficient current distribution across electrical circuits. According to a report by the International Electrotechnical Commission, improper connections and suboptimal feed units are responsible for approximately 30% of electrical failures in industrial settings. Therefore, understanding the features and specifications of the top busbar end feed units can enhance reliability and safety in electrical installations.

Key specifications to consider include current rating, insulation type, and dimensions. For instance, high-quality units typically offer current ratings ranging from 100A to 5000A, catering to various industrial applications. The insulation material also plays a crucial role; epoxy resin is often favored for its high dielectric strength, while also providing durability against environmental factors. Furthermore, the physical dimensions of busbar end feed units should align with the overall layout of the electrical system, ensuring minimal resistance and heat generation. According to a study published in the Journal of Electrical Engineering, proper sizing of busbar units can reduce energy losses by up to 15% in large facilities.

Additionally, features such as thermal monitoring and modular design are increasingly important. Advanced busbar units now come equipped with thermal sensors that provide real-time data, helping to prevent overheating. Meanwhile, modular designs allow for easier maintenance and scalability, accommodating future electrical load requirements. Reports indicate that such features can significantly lower operational costs over time by enhancing system efficiency and reliability. These considerations form the backbone of modern electrical distribution solutions, making the selection of the right busbar end feed units a crucial aspect of electrical engineering.

| Model | Rated Current (A) | Length (mm) | Material | IP Rating | Applications |

|---|---|---|---|---|---|

| Unit A | 250 | 800 | Aluminum | IP55 | Industrial Plants |

| Unit B | 400 | 1000 | Copper | IP67 | Data Centers |

| Unit C | 630 | 1200 | Aluminum | IP54 | Commercial Buildings |

| Unit D | 800 | 1400 | Copper | IP65 | Power Stations |

| Unit E | 1250 | 1600 | Aluminum | IP66 | Manufacturing Units |

| Unit F | 1600 | 1800 | Copper | IP54 | Transportation |

| Unit G | 2000 | 2000 | Aluminum | IP67 | Heavy Machinery |

| Unit H | 2500 | 2200 | Copper | IP65 | Railway Systems |

| Unit I | 3000 | 2500 | Aluminum | IP68 | Renewable Energy |

| Unit J | 3500 | 3000 | Copper | IP65 | Data Centers and Labs |

Busbar end feed units play a crucial role in modern electrical systems, offering numerous advantages that enhance overall performance and reliability. One of the primary benefits of using these units is their ability to optimize electrical distribution. By connecting multiple busbars efficiently, they ensure that electrical power is transmitted effectively throughout a facility. This minimizes energy loss and enhances the overall efficiency of the electrical system, which is particularly important in large industrial settings where power demands can fluctuate significantly.

In addition to improving efficiency, busbar end feed units also contribute to enhanced safety and ease of maintenance. They are designed to accommodate current fluctuations and environmental changes, reducing the risk of overheating and potential electrical faults. Moreover, their compact design allows for more flexible installation options, making it easier to integrate them into existing electrical infrastructures. This translates into reduced downtime and lower maintenance costs, as technicians can access and service the units more easily. Overall, the incorporation of busbar end feed units in electrical systems leads to a streamlined and reliable distribution network, supporting both operational efficiency and safety standards.

This chart illustrates the efficiency ratings of the top 10 busbar end feed units in electrical systems. Higher efficiency ratings contribute to enhanced performance in electrical distribution.

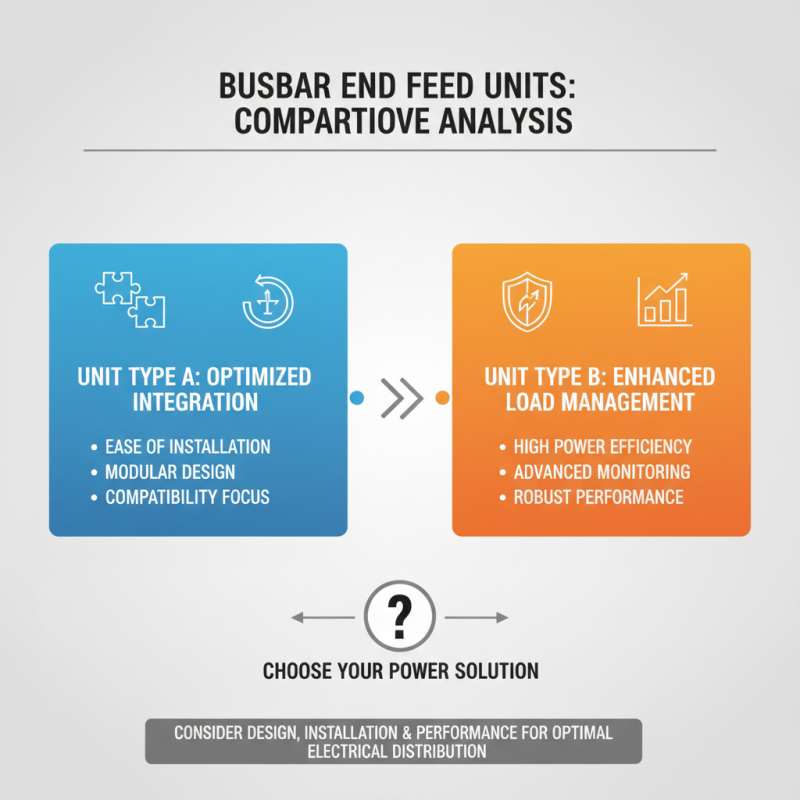

When exploring the market for busbar end feed units, it's essential to consider various factors that contribute to their efficiency and functionality in electrical distribution. A comparative analysis reveals that not all units are made equal; differences in design, installation requirements, and performance can significantly impact the overall electrical distribution system. Some units prioritize ease of integration, while others focus on enhanced load management capabilities, making it crucial for engineers and procurement managers to assess their specific needs before making a choice.

Tips: Always check for compatibility with existing infrastructure when selecting a busbar end feed unit. Look for units that offer flexible installation options to accommodate different space limitations and layout configurations. Additionally, pay attention to the manufacturer's specifications regarding load capacity and thermal management, as these factors are vital for maintaining system reliability and safety.

In addition, consider the maintenance requirements of the busbar end feed units you are evaluating. Units that allow for easier access and routine inspections can save time and costs in the long run. Moreover, exploring user reviews and expert opinions can provide valuable insights into real-world performance, helping to make a more informed purchasing decision.