Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

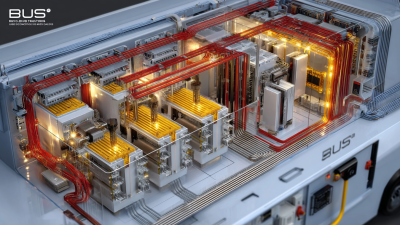

In the evolving landscape of electrical distribution, the importance of efficient and reliable systems cannot be overstated. Among the various methods of distributing electrical power, bus ducts have emerged as a preferred choice due to their ability to facilitate high-capacity power distribution while minimizing space requirements. As industries strive for greater energy efficiency and improved safety protocols in their operations, selecting the right bus duct becomes paramount.

In 2023, the advancements in technology and design have further enhanced the functionality and performance of bus ducts, catering to a diverse range of applications in commercial, industrial, and institutional settings. The growing trend towards modular systems highlights the flexibility and scalability that modern bus ducts offer, making them an ideal solution for facilities undergoing expansion or retrofitting. This article will explore the top 10 bus ducts that exemplify efficiency in electrical distribution, showcasing innovations that not only align with contemporary energy standards but also contribute to streamlined operations and cost savings.

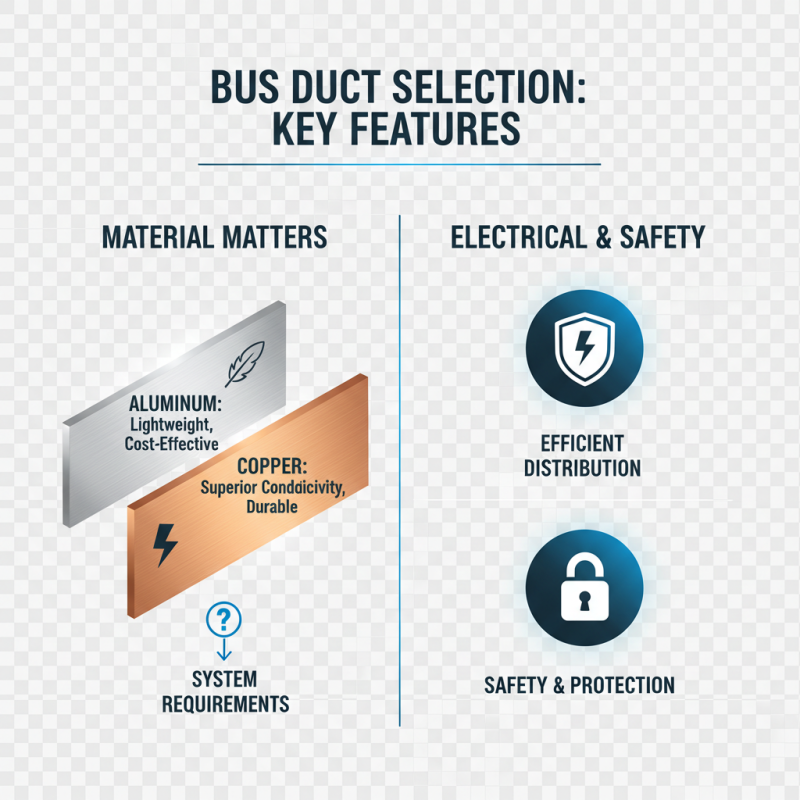

When selecting bus ducts for electrical systems, several key features should be prioritized to ensure efficient distribution and safety. Firstly, the material used in the bus duct is crucial. Aluminum and copper are the most common options, each with its own advantages. Aluminum is lightweight and cost-effective, while copper offers superior conductivity. Understanding the specific electrical and environmental requirements of your system will help in choosing the right material.

Another important consideration is the bus duct's insulation. High-quality insulation is essential to prevent electrical losses and ensure safety in various operating conditions. Look for insulation that can withstand temperature variations and has the appropriate dielectric strength for your application. Additionally, the design of the bus duct should facilitate easy installation and maintenance, including modular sections that can be expanded or modified based on future needs. Lastly, evaluate the bus duct’s rating capabilities to ensure they can handle your system's load requirements efficiently without overheating or causing system failures.

Bus ducts have emerged as a preferred choice for electrical distribution systems in modern facilities, offering numerous advantages over traditional methods. One significant benefit is their ability to reduce installation complexity and save space. Bus ducts can be easily routed along ceilings or walls, minimizing the need for extensive cable layouts and optimizing available square footage. This streamlined installation not only helps in maintaining a neat appearance but also reduces labor costs associated with installation.

Additionally, bus ducts provide improved safety and efficiency in electrical distribution. Unlike traditional wire runs, which may require more frequent checks and maintenance, bus ducts are designed for durability and offer increased protection against environmental factors. This makes them less prone to faults, reducing downtime and enhancing overall reliability.

**Tips for Effective Use of Bus Ducts:**

1. Ensure proper sizing based on your facility's power requirements to prevent overheating and maximize efficiency.

2. Regularly inspect and maintain bus ducts to uphold their performance and longevity.

3. Consider future expansion needs when selecting bus ducts to facilitate easy upgrades without significant investment.

By opting for bus ducts, organizations can enhance their electrical infrastructure, ensuring efficiency and reliability for years to come.

| Bus Duct Model | Current Rating (A) | Length (m) | Material | Advantages |

|---|---|---|---|---|

| Model A | 800 | 3.0 | Aluminum | Lightweight, Efficient Heat Dissipation |

| Model B | 1000 | 4.0 | Copper | High Conductivity, Durable |

| Model C | 1200 | 5.0 | Steel | Robust, Fire Resistant |

| Model D | 1500 | 6.0 | Aluminum | Corrosion Resistant, Lightweight |

| Model E | 1800 | 7.0 | Copper | Efficient Power Distribution, High Capacity |

| Model F | 2000 | 8.0 | Aluminum | Cost Effective, Easy Installation |

| Model G | 2200 | 9.0 | Copper | Highly Efficient, Compact Design |

| Model H | 2400 | 10.0 | Aluminum | Low Maintenance, High Reliability |

| Model I | 2600 | 11.0 | Copper | Superior Performance, High Capacity |

| Model J | 2800 | 12.0 | Aluminum | Eco-Friendly, Energy Efficient |

When it comes to electrical distribution, bus ducts serve as a vital component in ensuring power is delivered efficiently and safely. In 2023, various types of bus ducts have emerged, each designed to meet specific operational demands. The most common types include insulated bus ducts, air-insulated bus ducts, and hybrid solutions that combine both insulation and air-cooling technologies. Insulated bus ducts are prized for their compact design and ability to minimize thermal losses, making them ideal for facilities with limited space. On the other hand, air-insulated options typically feature larger profiles and provide exceptional heat dissipation, which can be advantageous in high-load applications.

Moreover, advancements in materials and construction techniques have led to the development of modular bus ducts, allowing for easy expansion and scalability. These systems permit quick modifications to electrical layouts without extensive downtime, catering to the evolving needs of modern infrastructures. Additionally, some manufacturers are now offering protective features against environmental factors, such as corrosion and extreme temperatures, providing enhanced durability and reliability. As industries continue to demand greater efficiency and flexibility in electrical distribution, understanding the distinct characteristics of each bus duct type will be crucial for selecting the appropriate system for specific applications.

In the rapidly evolving landscape of electrical distribution, bus ducts have emerged as a pivotal component, facilitating efficient power transmission in commercial and industrial settings. In 2023, key manufacturers are leading the charge in innovative bus duct technology, driven by a growing demand for energy efficiency and reliability. According to a recent market research report, the global bus duct market is anticipated to grow at a CAGR of approximately 6.2% from 2023 to 2028, reflecting the increasing adoption of advanced electrical distribution systems.

The top manufacturers are focusing on the development of modular and scalable bus duct solutions, which cater to the diverse needs of modern infrastructures. Industry experts indicate that these innovations not only enhance installation efficiency but also significantly reduce maintenance costs over time. Moreover, manufacturers are prioritizing sustainability by incorporating eco-friendly materials and design practices in their products. A report from a leading energy consultancy highlights that up to 30% of facility energy usage can be optimized through the integration of advanced bus duct systems, underscoring their critical role in achieving energy-efficient operations.

Additionally, these manufacturers are increasingly leveraging digital technologies for monitoring and management purposes. The introduction of smart bus duct systems, equipped with IoT capabilities, allows for real-time performance monitoring and predictive maintenance, which can lead to reduced downtime and improved operational efficiency. As the focus on sustainable and efficient electrical distribution grows, these key players in the bus duct market are well-positioned to shape the future of power distribution systems across various sectors.

The landscape of bus duct design is evolving rapidly, driven by the increasing demand for efficient electrical distribution systems. Future trends indicate a significant push towards the integration of smart technologies within bus ducts. These innovations will not only enhance monitoring capabilities but also enable real-time data collection on energy consumption, load distribution, and overall system performance. As industries become more focused on sustainability, the incorporation of energy-efficient materials and designs is expected to reduce waste and improve operational longevity.

Moreover, modular designs are set to gain traction in bus duct applications. This approach allows for easier customization and scalability, addressing the growing need for flexible electrical distribution solutions in diverse environments, from industrial facilities to commercial buildings. Improved thermal management solutions are also anticipated, ensuring higher efficiency and safety by minimizing overheating risks. Ultimately, these trends reflect a broader commitment to advancing electrical distribution technologies, aiming for greater efficiency and reliability in modern infrastructure.