Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

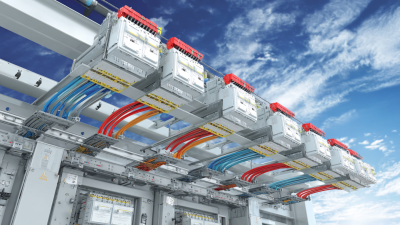

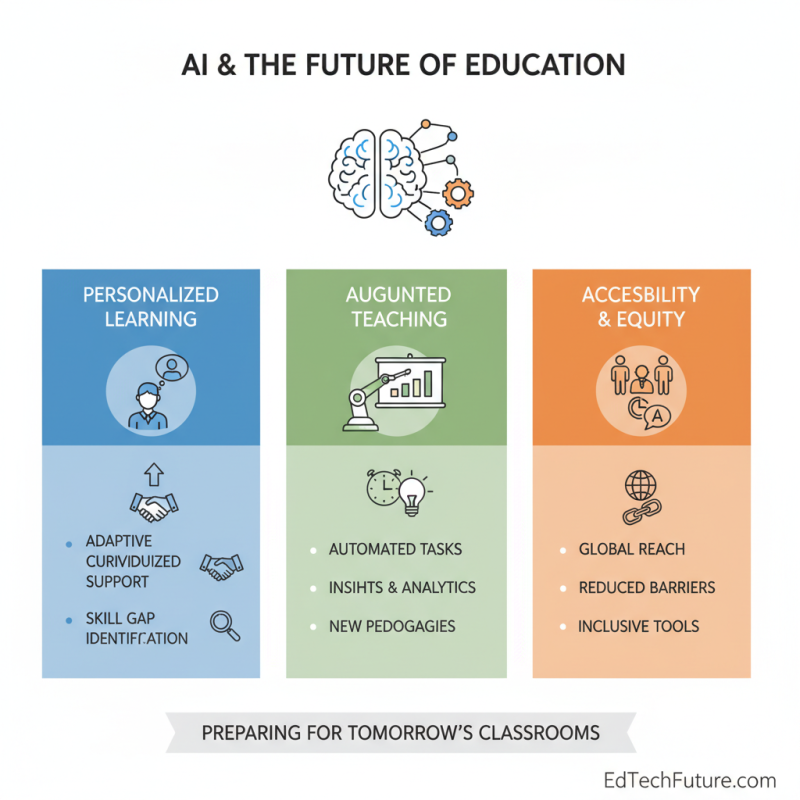

In the evolving landscape of electrical distribution, bus bars play a crucial role. "Bus bars are the backbone of any electrical system," says industry expert Dr. James Collins. According to a recent market analysis by Research and Markets, the global bus bar market size is projected to reach $7.2 billion by 2026, driven by the increasing demand for efficient power distribution.

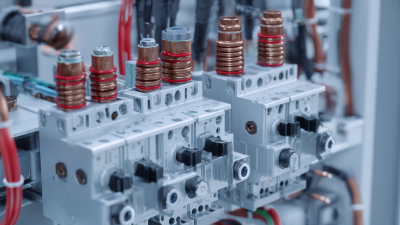

Bus bars are electrical conductors that facilitate the distribution of electricity in various applications, from industrial facilities to commercial buildings. Their design offers significant advantages, including compactness and high conductivity. However, selecting the right type of bus bar can be challenging. Factors like material, current rating, and installation environment must be considered to avoid inefficiencies. Reports indicate that non-optimized bus bar systems can lead to energy losses of up to 30%.

Despite advancements, the industry faces imperfections. Many are still unaware of the potential risks associated with improper bus bar installations. As we explore the different types of bus bars in 2026, understanding their applications will be essential for enhancing safety and performance in electrical systems.

Bus bars are essential components in electrical distribution systems. They help in conducting electricity between various parts. Understanding their types and materials is important for selecting the appropriate one for specific applications.

Bus bars can be categorized into several types: copper, aluminum, and steel. Copper bus bars are known for high conductivity and durability. They often handle high current loads, making them popular in industrial settings. Research shows that copper bus bars can conduct more electricity over a longer period than their competitors.

On the other hand, aluminum bus bars are lightweight and economical. They are ideal for applications requiring mass efficiency, such as in transportation. Steel bus bars, while less conductive, offer superior strength and stability. Many industries utilize steel bus bars for their mechanical support in harsh environments.

It's essential to choose the right material, as it affects both performance and cost. Data indicates that improper selection can lead to significant operational issues. This emphasizes the need for careful evaluation and sometimes, trial and error. Balancing performance and cost remains a key challenge for many professionals in the field.

Bus bars play a critical role in electrical systems across various industries. These conductive bars serve as common connections for multiple circuits. They distribute electricity efficiently, which is essential for energy management. According to a recent industry report, the bus bar market is projected to reach $10 billion by 2026. This growth indicates a rising demand for effective power distribution solutions.

In manufacturing and renewable energy sectors, bus bars are particularly vital. They ensure safety and reliability in high-voltage applications. For instance, in solar power plants, bus bars connect photovoltaic panels to inverters effectively. However, some projects may overlook proper material selection. Using inappropriate materials can lead to overheating and inefficiencies. Over time, inadequate maintenance can also impair performance, resulting in costly downtime.

The automotive sector is also increasingly adopting bus bar technology. As electric vehicles become more popular, the demand for compact and efficient bus bars is growing. These components not only save space but also reduce overall weight. Nevertheless, manufacturers face challenges, such as balancing design efficiency with cost-effectiveness. Such dilemmas highlight the need for innovative solutions in bus bar applications.

In the world of electrical engineering, bus bar designs play a crucial role in determining operational efficiency. Recent reports suggest that bus bars account for up to 20% of power distribution losses. Copper and aluminum are the most common materials. However, their efficiency can vary significantly based on design and application. For example, copper has a lower resistivity than aluminum. This means it can handle higher currents with less heat generation.

Despite these advantages, the cost of copper may deter some applications. A study by the International Energy Agency shows the increasing adoption of aluminum bus bars due to their lower initial costs. However, they require larger cross-sectional areas to match copper's capacity. This can lead to inefficient use of space. When considering long-term efficiency, copper often proves beneficial despite the upfront expense.

Specific applications, such as substations or industrial environments, demand more robust solutions. A 2022 study revealed that innovative bus bar designs, like the flat bus bar, can reduce air resistance. This results in improved thermal performance. Nonetheless, these advancements are not without challenges. It is essential to examine not just the materials used but also the application context to ensure optimal performance.

The future of bus bar technology is evolving quickly. Innovations are shaping how electrical systems operate. Lightweight materials are gaining traction. Copper and aluminum are being enhanced for improved performance. Lightweight bus bars show promise in reducing overall weight and improving efficiency. Designers are experimenting with hybrid materials too.

Smart bus bars are emerging. These integrate sensors for real-time monitoring. They can detect overheating or faults. This automated feedback improves safety and reliability. However, there’s a learning curve to implement such systems effectively. Not all installations are suited for smart technology yet.

Thermal management remains a challenge. Even with advancements, overheating is still a concern. New cooling methods are under consideration. Natural cooling systems, for example, could reduce energy consumption. Still, not every solution will fit every situation. Continuous research is vital to finding the right balance. Innovations can lead to unexpected complexities, necessitating careful planning.

Bus bar installations are crucial for electrical distribution. Proper maintenance ensures safety and efficiency. Regular inspections are vital. Look for signs of wear, corrosion, or overheating. These can signal potential failures. It’s essential to address issues promptly to prevent accidents.

Safety protocols must be a priority. Workers should wear appropriate protective gear. Electrical hazards are a serious concern. Using insulated tools reduces risk. Always follow lockout/tagout procedures during maintenance. These practices prevent accidental re-energization and enhance safety.

Training for staff is equally important. They should understand the specific requirements of bus bar systems. Encouraging a culture of safety helps in identifying risks early. There’s always room for improvement in safety measures. Reflecting on past incidents can help develop better protocols. Proper attention to these details minimizes risks and promotes longevity in electrical installations.