Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

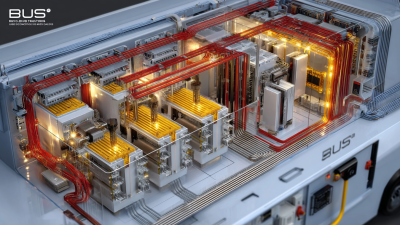

In recent years, the demand for reliable and efficient electrical distribution systems has surged, prompting many industries to seek out the best solutions for their power supply needs. Among these solutions, "Bus Duct in Electrical" applications has gained prominence due to its ability to accommodate high current capacity while enhancing safety and reducing space requirements. According to a report by the Global Bus Duct Market, the sector is projected to experience a CAGR of over 6% from 2021 to 2026, driven by the growing need for efficient power distribution in commercial and industrial facilities. This guide outlines the top strategies for sourcing high-quality bus ducts, emphasizing the importance of material selection, design, and supplier reliability to ensure optimal performance and longevity in demanding electrical environments. By leveraging expert insights and industry data, stakeholders can make informed decisions that support their operational goals while maintaining compliance with stringent safety standards.

Bus ducts, also known as busway systems, play a critical role in modern electrical applications by providing a reliable and efficient means of conducting electrical current across various components. According to a recent report by ResearchAndMarkets, the global bus duct market is anticipated to grow from USD 3.5 billion in 2022 to USD 5.2 billion by 2027, driven by increasing demand in commercial buildings and industrial setups. This surge is attributed to the continuous advancements in energy systems and the necessity for efficient power distribution in a landscape that is increasingly leaning towards sustainable energy solutions.

A comprehensive overview of bus ducts reveals their significance in enhancing electrical reliability while minimizing the required footprint. Bus ducts are preferred over traditional wiring for several reasons, including their ability to manage high currents with reduced electrical losses. Industry data shows that bus duct systems can lower energy losses by up to 30% compared to conventional cables, making them an attractive option for reducing operational costs. Furthermore, they facilitate ease of installation and adaptability, allowing for future modifications as electrical demands evolve. As organizations strive to optimize their energy infrastructures, understanding the advantages and best sourcing strategies for high-quality bus duct systems becomes paramount.

This bar chart illustrates the distribution of bus duct materials used in various electrical applications. The data represents the percentage usage of different types of bus ducts based on industry research.

When sourcing high-quality bus duct for electrical applications, several key factors must be taken into consideration to ensure optimal performance and longevity. First and foremost, material selection plays a critical role. According to the “2023 Electrical Components Market Report,” aluminum and copper are the predominant materials used in bus duct construction due to their excellent conductivity and resistance to environmental factors. Choosing the right type can significantly impact the efficiency and heat dissipation of the electrical system.

Another important factor is the design and configuration of the bus duct. A well-designed bus duct system not only maximizes space utilization but also minimizes installation costs and enhances system reliability. The report highlights that systems designed with modular configurations can reduce installation time by up to 30%. Additionally, it is crucial to evaluate the manufacturer's reputation and adherence to industry standards, such as those set by the International Electrotechnical Commission (IEC). Engaging with suppliers who emphasize compliance can lead to improved safety and performance outcomes, as highlighted in various studies showcasing reduced failure rates in certified products.

Lastly, attention to environmental factors and application-specific requirements cannot be overlooked. Bus duct systems exposed to harsh conditions may require coatings or enclosures that safeguard against corrosion. The data shows that investing in high-quality protection can extend the lifespan of electrical systems by as much as 20%. In sum, considering materials, design, manufacturer standards, and environmental adaptability are essential strategies for sourcing top-notch bus duct solutions in electrical applications.

When searching for reliable bus duct solutions in electrical applications, it’s crucial to consider the manufacturers and brands that lead the industry. According to a recent market analysis report by Mordor Intelligence, the global bus duct market is projected to reach USD 6.32 billion by 2026, growing at a compound annual growth rate (CAGR) of 5.4%. This substantial growth highlights the increasing demand for high-quality bus ducts, especially in sectors like manufacturing, commercial construction, and renewable energy.

Leading manufacturers such as Eaton, Siemens, and Schneider Electric are renowned for their commitment to innovation and quality. Eaton, for instance, offers bus duct systems that are designed to enhance energy efficiency, which is a growing concern in modern electrical infrastructure. Their energy-efficient models can reduce operational costs and enhance system reliability. Similarly, Siemens provides an extensive range of bus duct solutions that comply with rigorous safety standards, ensuring durability and performance. As industries pivot towards sustainable solutions, exploring these top brands will not only provide access to quality products but also align with the growing trend of eco-friendly practices in electrical applications.

When sourcing high-quality bus duct for electrical applications, evaluating its quality and specifications is paramount. According to the International Electrotechnical Commission (IEC) standards, the quality of bus duct systems can significantly impact energy efficiency and safety in electrical installations. A well-designed bus duct should meet or exceed these standards, ensuring optimal conductivity and minimal energy loss. Reports indicate that using high-quality materials can reduce operational failures by up to 30%, which underscores the importance of thorough evaluations.

When assessing bus ducts, it's crucial to consider several key specifications, including thermal ratings, current carrying capacity, and environmental resistance. The latest industry data reveals that manufacturers offering bus ducts with a thermal rating of at least 120°C can improve energy efficiency by 15% in high-load scenarios. Additionally, examining the corrosion resistance properties can ensure longevity, particularly in harsh environments; materials like aluminum and stainless steel have shown superior performance in tests conducted by the National Electrical Manufacturers Association (NEMA). A thorough assessment of these factors not only facilitates compliance with regulatory requirements but also enhances the reliability of electrical systems in diverse applications.

When considering the long-term performance of electrical systems, investing in premium bus duct is a strategic move that pays off. Reports from industry experts indicate that quality bus duct can reduce overall operational costs by up to 20% over its lifespan. This is primarily due to its durability and enhanced efficiency in power distribution.

High-quality materials resist degradation and corrosion, which translates to fewer maintenance interventions and longer replacement cycles, ultimately leading to significant savings.

Moreover, energy efficiency is a major factor in the decision to invest in premium bus duct. According to a study by the National Electrical Manufacturers Association (NEMA), facilities using high-grade bus duct systems report lower energy losses, with some models achieving efficiencies exceeding 95%. This not only contributes to a facility's operational bottom line but also aligns with sustainability initiatives by reducing energy consumption. Therefore, while the upfront cost may be higher for premium products, the long-term benefits—including reduced maintenance, lower operational costs, and enhanced energy efficiency—make it a wise investment for any electrical application.