Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the evolving landscape of energy management, optimizing Busbar Distribution systems has emerged as a critical focus for enhancing efficiency and reliability. According to the Global Energy Management Report 2023, businesses implementing advanced busbar solutions have reported up to a 20% reduction in energy losses, underscoring the pivotal role of innovative electrical distribution methods. By harnessing the potential of Busbar Distribution, enterprises can not only streamline their energy consumption but also significantly reduce operational costs, paving the way for a more sustainable future.

As highlighted by Dr. Emily Zhao, a leading expert in electrical engineering, "The future of energy management lies in the intelligent design and optimization of Busbar Distribution systems." Dr. Zhao’s insights reflect a growing consensus among industry leaders that integrating new technologies and materials in busbar design can lead to superior performance and enhanced energy savings. As businesses increasingly seek reliable and efficient energy solutions, understanding the intricacies of Busbar Distribution will be essential for achieving operational excellence and sustainability objectives.

Busbar distribution systems are critical for efficient energy management in both industrial and commercial applications. These systems serve as the backbone for electrical distribution, providing a centralized method to distribute electrical power from transformers to various loads. Understanding the layout and operation of busbar systems is essential for optimizing energy usage and ensuring reliability. A well-designed busbar distribution system can improve energy efficiency, reduce losses, and enhance the overall reliability of the electrical network.

**Tips for Optimization:** First, conduct regular maintenance checks on busbars to identify any wear and tear that might affect performance. Second, ensure that the busbar design is appropriately sized for the load it will carry; this helps prevent overheating and increases longevity. Lastly, consider integrating smart monitoring systems to track real-time energy usage and identify any inefficiencies within the distribution network.

Investing in proper busbar distribution not only enhances energy management but also contributes to a more sustainable operation. By prioritizing busbar efficiency, businesses can significantly lower their energy costs and reduce their carbon footprint, all while maintaining a stable and safe electrical supply.

| Dimension | Description | Value |

|---|---|---|

| Voltage Level | Standard operating voltage for busbar systems | 400V |

| Current Rating | Maximum current the busbar can handle | 1000A |

| Material Used | Material used for the busbar construction | Copper |

| Heat Dissipation | Heat dissipation capacity | 50W/m² |

| Length of Busbar | Standard length of the busbar | 2m |

| Safety Standards | Standards that the busbar conforms to | IEC 61439 |

| Installation Type | Type of installation for the busbar system | Indoor |

Effective energy management is crucial for optimizing busbar distribution, particularly as energy demands grow. One key factor in achieving this is understanding the load characteristics of the system. By analyzing current and forecasted demand, energy managers can design busbar configurations that cater to specific load profiles. This proactive approach allows for better efficiency, reduced losses, and the ability to accommodate fluctuating energy needs without compromising performance.

Additionally, technology integration plays a vital role in enhancing energy management. Implementing advanced monitoring and control systems enables real-time data collection and analysis, leading to informed decision-making. Smart meters and energy management software allow operators to track energy flow and identify inefficiencies in the distribution network. By leveraging these technologies, organizations can streamline operations, minimize energy waste, and proactively address potential issues before they escalate. Ultimately, optimizing these factors contributes significantly to a more sustainable and efficient energy management strategy.

In optimizing busbar design and layout for efficient energy management, several key strategies can be employed. First, selecting the appropriate materials is crucial. Using high conductivity materials such as copper or aluminum reduces resistive losses, thereby improving overall efficiency. Additionally, the geometry of the busbar should be designed to minimize the path length for electrical current, which also helps in lowering energy losses.

Another important aspect is the careful planning of the busbar layout. This entails ensuring that the busbars are arranged to reduce electromagnetic interference and thermal effects. Spacing and orientation play significant roles in maintaining optimal performance, as they can impact both cooling and the potential for short circuits. Furthermore, incorporating modular designs can allow for future scalability and flexibility, accommodating changes in energy demand without requiring complete system redesigns. By focusing on these strategies, energy management systems can achieve higher efficiency and reliability.

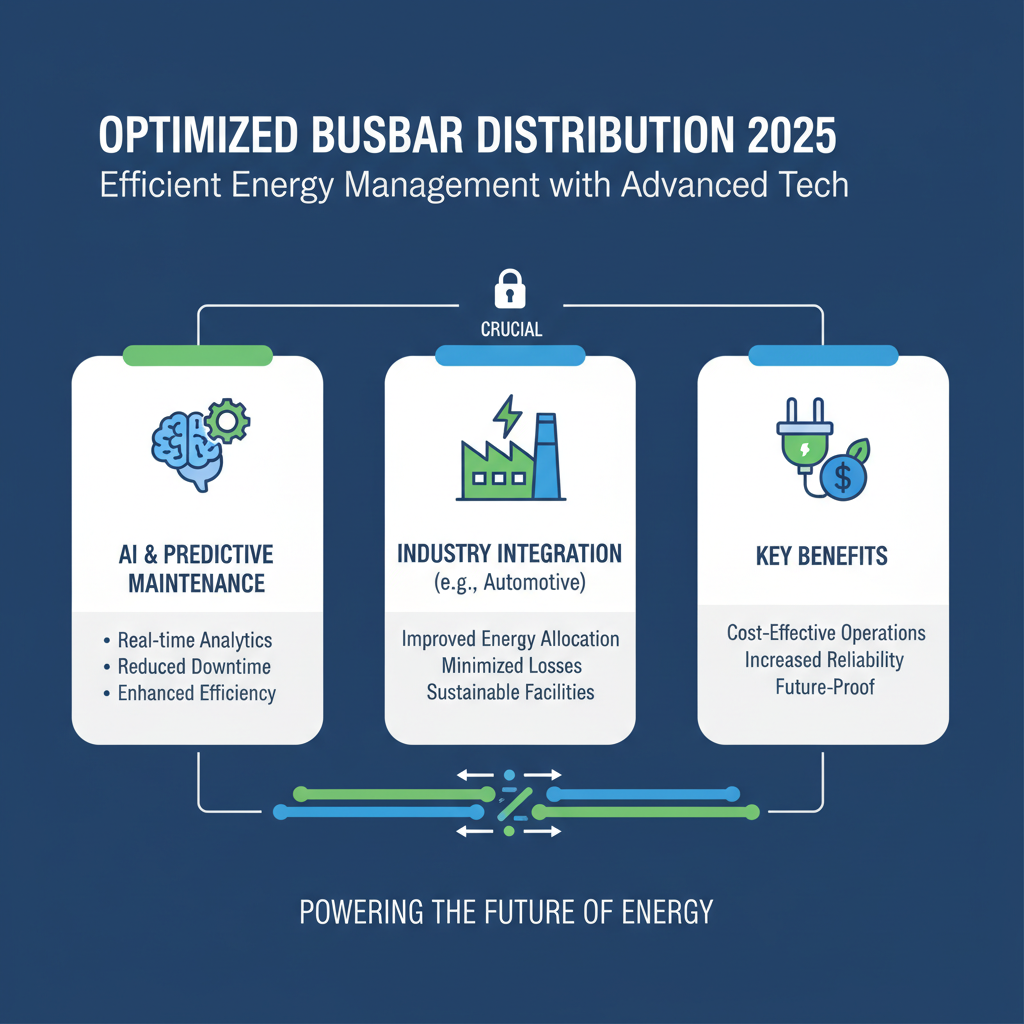

In 2025, optimizing busbar distribution is crucial for efficient energy management, especially as advanced technologies become integral to various industries. The implementation of cutting-edge solutions like AI and predictive maintenance has been proven to enhance operational efficiency. For instance, in the automotive sector, AI technologies facilitate real-time analytics, leading to significant reductions in downtime and waste. Integrating these technologies into busbar systems can similarly improve energy allocation and minimize losses, making facilities more sustainable and cost-effective.

Tips: Emphasize data analytics for real-time monitoring of energy consumption. Regular maintenance schedules powered by AI can identify potential faults before they escalate into significant issues.

Furthermore, as industries explore the potential of advanced automation, the application of AI in energy management is becoming increasingly relevant. From smart grid solutions to automated monitoring systems, these technologies enable businesses to respond dynamically to energy demands. By adopting such innovative approaches, companies can ensure their energy distribution systems are not only efficient but also resilient against fluctuating operational requirements.

Tips: Incorporate AI algorithms to analyze and predict energy usage patterns. Collaborating with tech innovators can provide businesses with tailor-made solutions that enhance energy management strategies.

In the realm of energy management, effective monitoring and maintenance practices are crucial for optimizing busbar distribution systems. According to the International Energy Agency (IEA), over 40% of global energy losses in industrial sectors can be attributed to inefficient electrical distribution systems. By implementing robust monitoring solutions, organizations can gain real-time insights into their busbar operations, allowing for timely adjustments to enhance efficiency. Technologies such as IoT sensors and advanced metering can help detect anomalies in voltage and current, reducing downtime and preventing potential failures.

Routine maintenance is another critical component in ensuring sustainable performance. The Electric Power Research Institute (EPRI) states that predictive maintenance strategies can lead to a 25-30% reduction in maintenance costs and an increase in system reliability. Regular inspections and testing, coupled with data analytics, enable facility managers to pinpoint areas in need of immediate attention. By prioritizing maintenance tasks based on real-time data, businesses can extend the lifespan of their busbar systems while minimizing the environmental impact associated with energy waste.