Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

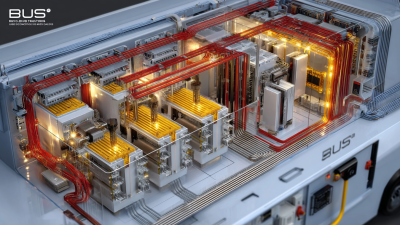

In the ever-evolving landscape of electrical distribution systems, maximizing efficiency is crucial for operational success. One innovative solution that has emerged is the Sandwich Bus Duct, a compact and versatile system designed to optimize power distribution while minimizing energy losses. According to a recent industry report by MarketsandMarkets, the global bus duct market is projected to grow from $2.76 billion in 2020 to $4.08 billion by 2025, reflecting a compound annual growth rate (CAGR) of 8.5%. This surge can be attributed to the increasing demand for reliable and efficient power distribution in various sectors, including manufacturing, commercial buildings, and data centers. Implementing Sandwich Bus Duct solutions not only enhances electrical efficiency but also simplifies installation and maintenance, ultimately leading to reduced operational costs and improved system reliability. As organizations strive to enhance their infrastructure, understanding how to effectively leverage Sandwich Bus Duct technology becomes essential for achieving optimal performance.

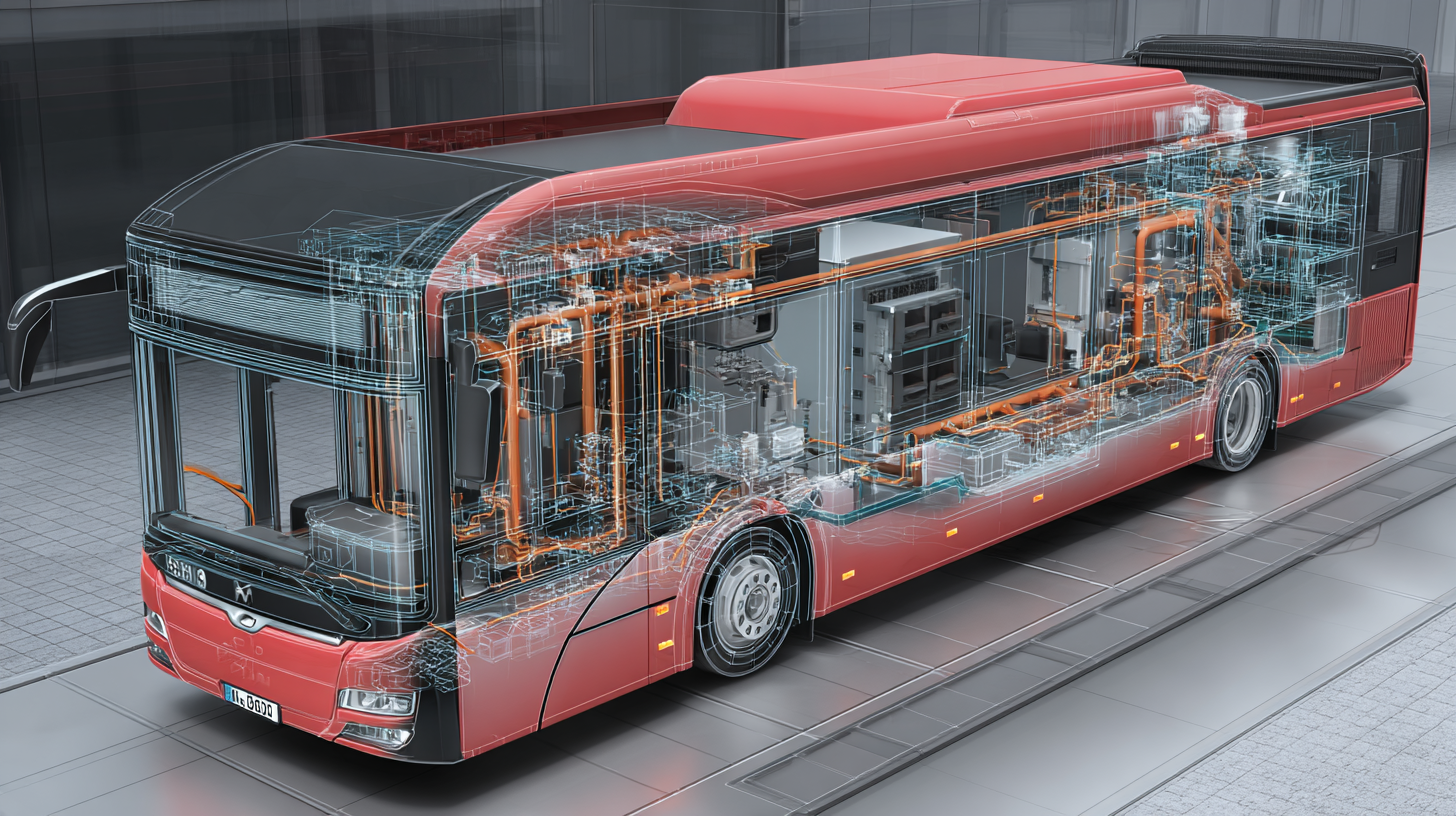

Sandwich bus duct systems present a unique and efficient solution for electrical power distribution in various industrial settings. These systems are characterized by their compact design, which not only saves space but also allows for easier installation and maintenance compared to traditional bus systems. According to industry reports, the use of sandwich bus ducts can reduce installation time by up to 30%, which is crucial in projects where time is of the essence. Additionally, their inherent modularity enables seamless scalability, making them ideal for businesses anticipating future growth.

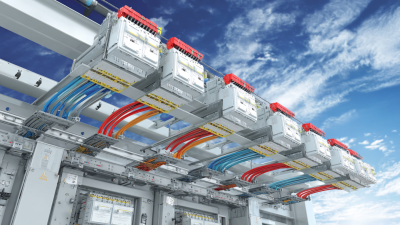

The benefits of sandwich bus duct solutions extend beyond space-saving and rapid installation. They provide enhanced safety features, such as reduced risk of overheating due to their ventilated design, which aligns with industry standards for electrical infrastructure. A recent study highlighted that the use of advanced materials in these systems can improve thermal performance by as much as 15%, ensuring consistent operational efficiency and longevity. As corporations increasingly seek sustainable solutions, integrating sandwich bus duct systems can ensure compliance with energy efficiency regulations while minimizing operational costs.

When selecting sandwich bus duct solutions, several key factors play a crucial role in maximizing efficiency. First, the power rating of the bus duct is essential; it must match the electrical load requirements of the facility. Industry reports indicate that mismatching can lead to overheating, which affects energy efficiency and can result in significant downtime. For optimum performance, choosing sandwich bus ducts with a higher ampacity rating than necessary can accommodate future expansion or unexpected load increases.

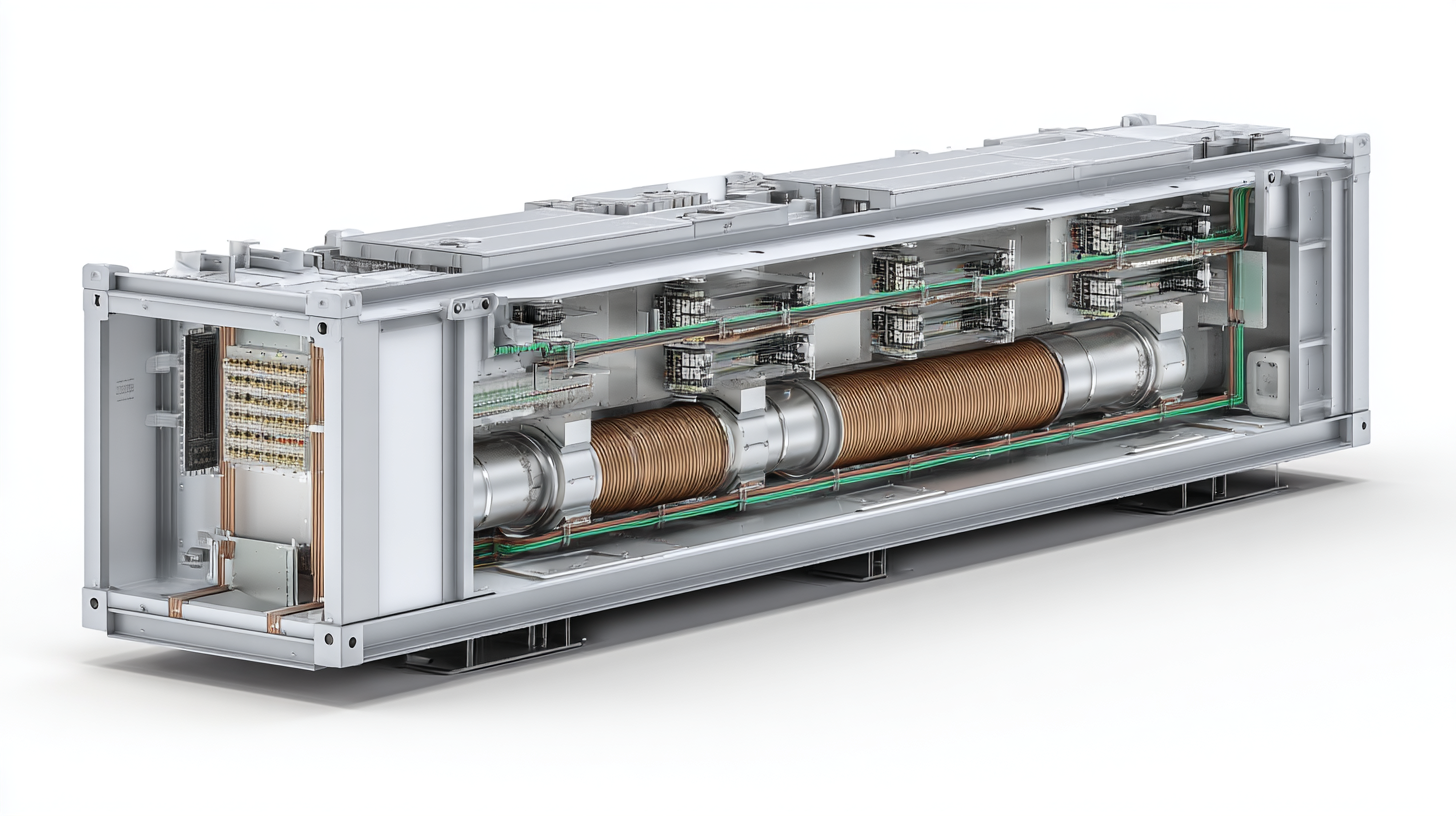

Another important consideration is the thermal management capabilities of the bus duct. According to a study by the Electric Power Research Institute, properly designed sandwich bus ducts can reduce thermal losses by up to 30% compared to traditional bus systems. This is achieved through effective insulation materials and design that maintain lower operating temperatures, thus enhancing overall system efficiency. Additionally, the ease of installation and maintenance should not be overlooked; modular sandwich bus duct systems can reduce installation time by 50%, translating to lower labor costs and faster project turnarounds.

When it comes to maximizing efficiency with sandwich bus duct solutions, the installation and maintenance practices are critical for ensuring optimal performance. According to a recent report by Research and Markets, the global bus duct market is expected to grow at a CAGR of 6.4% from 2021 to 2026. This growth is largely driven by the increasing demand for efficient power distribution systems in industrial applications. Proper installation techniques, such as ensuring adequate support and alignment with voltage requirements, can enhance the duct's performance and longevity.

Regular maintenance of sandwich bus ducts is equally vital. The National Electrical Manufacturers Association (NEMA) recommends inspecting bus ducts for signs of wear or damage at least once a year. This includes checking for any loose connections, corrosion, and ensuring that the insulation remains intact. According to a study from the Institute of Electrical and Electronics Engineers (IEEE), up to 20% of electrical failures in industrial settings can be traced back to inadequate maintenance practices. By following best maintenance protocols, organizations can not only extend the lifespan of their sandwich bus ducts but also minimize outages and costly repairs, leading to a more efficient power distribution system.

Sandwich bus duct systems have become a critical component in modern electrical distribution, providing efficient power transmission in industrial and commercial applications. Innovative technologies are enhancing the performance of these systems by improving their thermal efficiency, reducing installation space, and increasing their overall reliability. Advanced materials used in the construction of sandwich bus ducts allow for better thermal management, minimizing heat generation and losses, which is essential for maintaining optimal operational conditions.

Additionally, recent developments in smart monitoring technologies contribute significantly to maximizing the efficiency of sandwich bus ducts. These systems utilize sensors and IoT connectivity to provide real-time data on voltage, current, and temperature fluctuations. This not only helps in predictive maintenance but also allows for immediate corrective actions that can prevent downtime. The integration of automation and control systems enhances load balancing across the ducts, further optimizing energy use and ensuring that performance remains at its peak even under varying operational demands.

Sandwich bus duct solutions have been successfully implemented in various industries, showcasing their efficiency and reliability. One notable case study involves a large manufacturing facility that transitioned from traditional cabling to sandwich bus duct systems. This shift not only streamlined their power distribution but also significantly reduced installation time and labor costs. The facility reported a 30% decrease in downtime during the installation period, allowing for smoother operations and faster project completion.

Sandwich bus duct solutions have been successfully implemented in various industries, showcasing their efficiency and reliability. One notable case study involves a large manufacturing facility that transitioned from traditional cabling to sandwich bus duct systems. This shift not only streamlined their power distribution but also significantly reduced installation time and labor costs. The facility reported a 30% decrease in downtime during the installation period, allowing for smoother operations and faster project completion.

Another compelling example comes from the data center sector, where a company adopted sandwich bus duct solutions to meet their high-density power requirements. The installation of this advanced system provided enhanced thermal management and optimized space utilization. As a result, the data center was able to increase its capacity without expanding its physical footprint, proving that sandwich bus ducts can be a game-changer in environments where space is at a premium. Feedback from the implementation showed improved energy efficiency and a decrease in maintenance needs, highlighting the long-term benefits of this innovative solution.