Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

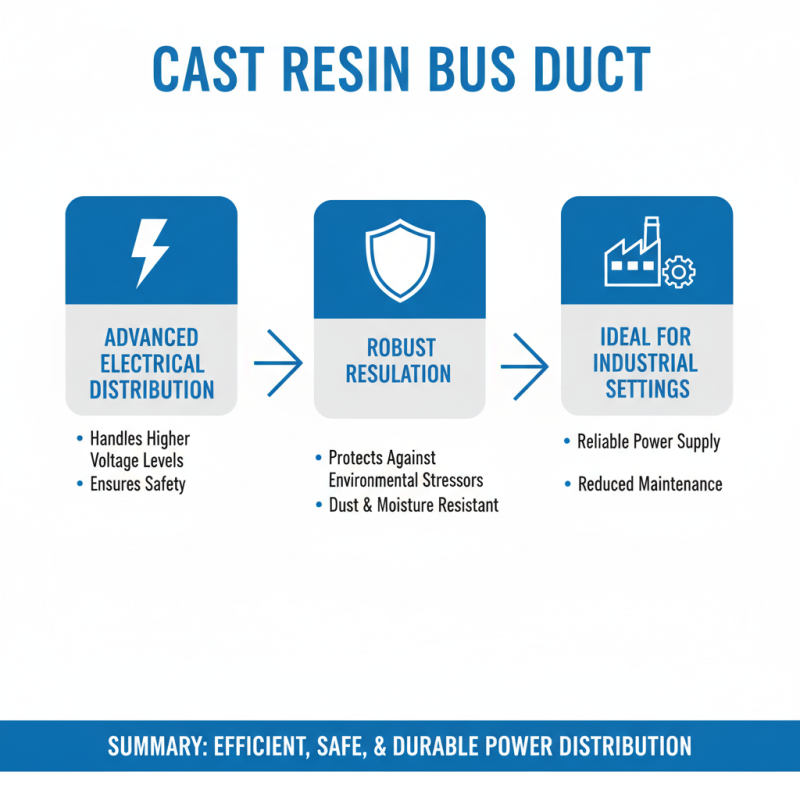

In today's electrical distribution landscape, efficiency is paramount. The demand for reliable energy solutions is increasing. According to industry reports, the global bus duct market is expected to reach $4.7 billion by 2026, growing at a CAGR of 7.4%. This highlights the rising importance of effective systems like Cast Resin Bus Duct.

Cast Resin Bus Duct offers several advantages. It is resistant to moisture and chemicals, ensuring longevity in various environments. Furthermore, its installation can improve energy efficiency by reducing transmission losses. However, challenges remain in the installation process. Improper handling can lead to performance issues and project delays.

To ensure optimal performance, careful planning is essential. Understanding the specifics of Cast Resin Bus Duct installation can make a significant difference. While many projects are completed smoothly, others fall into common pitfalls. Continuous reflection on installation practices is vital. The benefits are clear, but cautious execution is necessary for success.

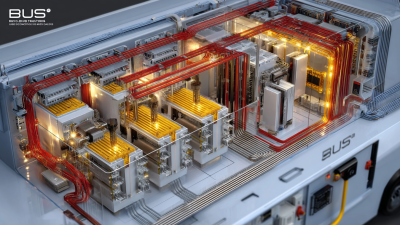

Cast resin bus duct is an advanced electrical distribution system. It effectively handles higher voltage levels while ensuring safety. The resin insulation is robust, protecting against environmental stressors. This feature is essential for industrial settings.

One significant advantage is its compact design. It requires less space than traditional systems. This makes installation easier in tight areas. However, planning the layout can be challenging. Ensuring optimal alignment and access points is critical. Mistakes here can lead to performance issues.

Cast resin bus ducts also have a longer lifespan. This reduces maintenance needs, but improper installation can negate these benefits. Regular inspections are necessary to maintain efficiency. Many users overlook this aspect, leading to potential failures. Adopting a proactive approach is crucial for longevity and reliability in electrical infrastructure.

When preparing for the installation of cast resin bus duct, gathering the right tools and materials is vital. You'll need insulated tools, such as pliers and screwdrivers. Also, a torque wrench plays a crucial role in ensuring connections are secure. Make sure you have a level, measuring tape, and a utility knife handy. These tools will help you achieve precision and accuracy during installation.

In addition to tools, be prepared with high-quality materials. This includes the bus duct sections, connectors, and mounting brackets. Ensure you have proper insulation materials as well. It's often overlooked, but having the right amount of cable ties will assist in organizing wiring neatly. Sometimes, workers forget to check for corrosion on older equipment. This can create unexpected challenges.

The workspace should be clear and well-lit. Lack of visibility may lead to mistakes. Rushing through can result in incorrect fittings. Take time to read through instructions before starting. Although it can be tedious, this step can prevent costly errors later on. Having a checklist can help ensure all necessary items are on hand. This preparation phase is crucial for a successful installation.

Installing cast resin bus duct involves several essential steps for efficient electrical distribution. Start by assessing the installation site. Ensure that the area is clean and free from any obstruction. A study from the Electrical Power Research Institute highlights that a clutter-free environment can reduce installation errors by 30%. Preparation is key. Gather all necessary tools and materials. Make sure you have appropriate personal protective equipment.

Next, lay out the bus duct components according to the design specifications. Measure carefully to avoid misalignment. Misalignment can lead to overheating and power loss. According to the National Electrical Manufacturers Association, improper installation can cause up to a 15% decrease in system performance. Secure each segment properly. Use appropriate fasteners to ensure durability. Any negligence in this step could result in future maintenance challenges.

When connecting the bus duct sections, follow the manufacturer's guidelines. Over-tightening can damage components. Remember to check connections regularly post-installation. It's essential to perform periodic testing to identify any potential issues early. Reports indicate that timely testing can prevent 70% of electrical failures in distribution systems. Although the process may seem straightforward, attention to detail is crucial. Small mistakes can lead to significant consequences.

When installing cast resin bus ducts, safety is paramount. Ensure your workspace is organized. Remove any hazards, like loose materials or tools. Wear proper personal protective equipment (PPE). This includes gloves, goggles, and hard hats. Electrical work can be risky, and taking precautions can save lives.

During the installation process, be cautious when handling heavy duct sections. Teamwork is crucial here. Have a partner assist in lifting and positioning the sections. Miscommunication can lead to accidents. So, establish clear signals in advance.

Tips: Always double-check connections before powering up the system. Proper alignment of sections is vital for efficiency. Additionally, inspect the duct before and after installation to identify potential flaws. Remember, if something feels off, take a step back. It's better to reassess than rush into a decision.

Regular testing and maintenance of cast resin bus ducts enhance their efficiency and prolong their lifespan. According to a 2022 industry report, well-maintained bus ducts can reduce energy losses by up to 30%. Regular inspections are crucial. Check for signs of wear and tear, such as insulation damage or loose connections. These issues can lead to overheating or electrical failures. Monitoring temperature is essential. Elevated temperatures can indicate problems and should trigger immediate investigation.

Maintenance should include cleaning and securing connections. Dust and debris can obstruct performance, resulting in inefficiencies. A study by the Electrical Safety Foundation found that 25% of electrical fires occur due to poorly maintained equipment. Routine checks and timely repairs can mitigate risks. Consider implementing a maintenance schedule. This proactive approach prevents minor issues from becoming costly repairs. A focus on these details will ultimately lead to optimal performance and reliability in your electrical distribution system.

| Dimension | Unit | Value | Notes |

|---|---|---|---|

| Current Rating | A (Amperes) | 6000 | Typical for medium voltage applications |

| Rated Voltage | kV (Kilovolts) | 0.4 | Common in industrial settings |

| Temperature Rating | °C (Degrees Celsius) | 90 | Max operational temperature |

| Length of Duct | m (Meters) | 5 | Standard length for installation |

| Weight | kg (Kilograms) | 150 | Weight including insulation |

| Installation Method | - | Mounting Brackets | Use proper support for installation |

| Maintenance Frequency | - | Annual | For optimal performance |