Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

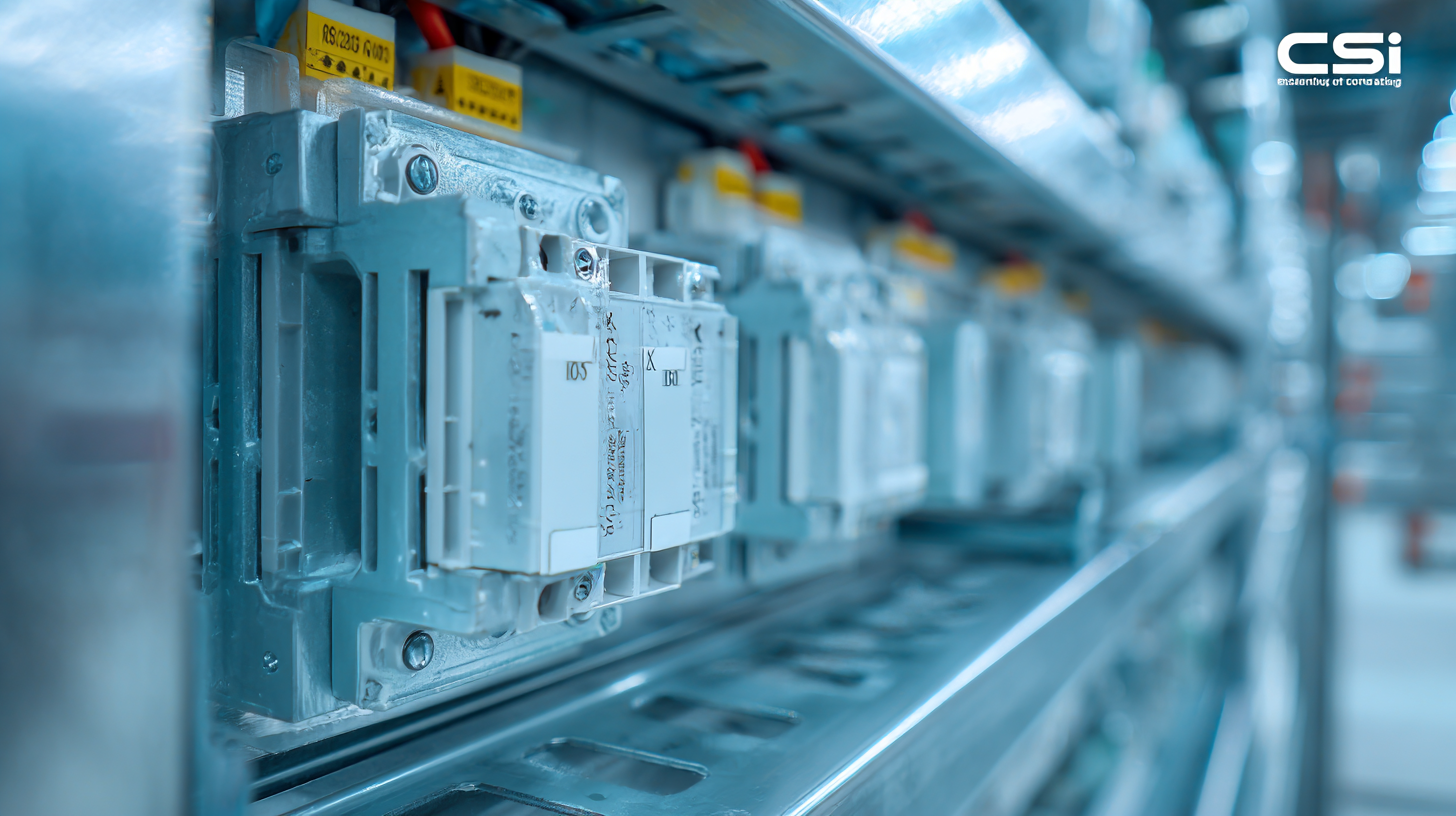

In today's competitive manufacturing landscape, ensuring compliance with global standards has become paramount, especially in the electric distribution sector. The Bus Duct Trunking System plays a critical role in the safe and efficient distribution of electrical power, being utilized extensively across various industries. Recent market analyses project that the global Bus Duct Trunking System market will witness a significant growth rate of approximately 6.5% annually, driven by the increasing demand for efficient energy management solutions and the rising adoption of smart grid technologies.

As outlined in the International Electrotechnical Commission (IEC) standards, effective certifications not only enhance product reliability but also facilitate smoother import and export processes. This blog will guide you through the essential product specifications and certification requirements needed to navigate the complexities of global trade, ensuring that your Bus Duct Trunking System meets both domestic and international compliance standards.

In the rapidly evolving global market for electrical distribution, identifying high-quality bus duct trunking system suppliers requires a keen understanding of both product specifications and manufacturer credentials. A critical first step is to verify that the suppliers meet international standards and certifications relevant to the industry. This includes ensuring compliance with ISO standards, which reflect not only the quality of their products but also their commitment to safety and environmental management.

Moreover, it's essential to conduct thorough research on potential suppliers’ reputations within the industry. Look for suppliers with a proven track record, supported by customer testimonials and case studies. Engaging with industry trade shows and forums can provide valuable insights, allowing buyers to connect with reliable manufacturers and gain firsthand knowledge of their offerings. By focusing on these key aspects, stakeholders can effectively navigate the complexities of the global market and source bus duct trunking systems that not only meet their operational needs but also adhere to the highest standards of quality and safety.

When dealing with bus duct systems, understanding the import and export certification requirements is crucial for ensuring compliance and achieving success in the global marketplace. Different countries have varying standards, and manufacturers must familiarize themselves with these regulations to avoid costly delays and penalties. Certifications such as UL, CE, and IEC provide assurance of the system's safety, performance, and suitability for specific applications. This not only helps in gaining trust from customers but also opens up new markets.

Moreover, the documentation process for certifications can be complex and time-consuming. Companies must prepare technical files that include design specifications, testing data, and adherence to national and international standards. It is essential to engage with third-party testing and certification bodies early in the development stage to align the product design with required standards. Understanding these compliance requirements not only streamlines the import-export process but also enhances the overall quality and reliability of the bus duct trunking system.

When evaluating bus duct trunking manufacturers, several key factors need to be considered to ensure the selection of a quality system that meets global standards. Firstly, it is crucial to assess the manufacturer’s compliance with international certifications. These certifications not only validate the safety and reliability of the products but also reflect the manufacturer's commitment to maintaining high-quality standards. A robust certification portfolio can significantly enhance a manufacturer's credibility in the competitive market of electrical busbar trunking systems.

Moreover, the recent research on the electrical busbar trunking system market indicates a growing demand projected to rise substantially by 2025-2033. The report highlights that technological advancements and the increasing need for energy-efficient solutions are driving this trend. Therefore, when choosing a manufacturer, it is wise to consider their ability to innovate and adapt to these market demands.

Factors such as customer service quality also play a vital role in the decision-making process, revealing how responsive and supportive the manufacturer can be throughout a project's lifecycle. Overall, a thorough assessment of these elements will aid in identifying the most suitable bus duct trunking solution for various applications.

In today's interconnected world, compliance with global standards is crucial for businesses involved in the import and export of bus duct trunking systems. Each country may have its own regulations, but adhering to internationally recognized standards, such as IEC and UL, is essential for fostering trust and ensuring product safety. Companies can navigate these complexities by developing effective compliance strategies that include thorough research on applicable standards, engaging with regulatory bodies, and staying updated on changes in legislation.

One effective strategy is to establish a dedicated compliance team that continuously monitors regulations in key markets. This team can conduct regular audits of products and processes to ensure alignment with global standards. Additionally, investing in training programs for staff can help cultivate a culture of compliance within the organization, ensuring that everyone from design to production understands the importance of adhering to standards. By prioritizing compliance, businesses not only enhance their reputation but also minimize the risk of costly recalls and fines that can arise from non-compliance.

This chart illustrates the number of countries that have adopted various global certifications for bus duct trunking systems. Understanding these certifications is crucial for ensuring compliance with international standards.

Building long-term partnerships with reliable bus duct suppliers is vital for ensuring consistent quality and compliance with international standards in the electrical industry. When selecting a supplier, it’s essential to evaluate their certifications and adherence to global standards. A supplier that possesses the right certifications demonstrates their commitment to quality and safety, which directly impacts the performance and reliability of the bus duct trunking systems. Engaging with certified suppliers not only mitigates risks but also enhances the overall efficiency of your projects.

Moreover, fostering a strong relationship with your suppliers can lead to more favorable terms and better support throughout the project lifecycle. This synergy allows for collaborative problem-solving and innovation, resulting in customized products that meet specific needs. As the market for bus duct systems continues to evolve, having a dependable supplier who understands the importance of adaptability and responsiveness can give your business a competitive edge. By prioritizing these partnerships, companies can ensure that they have access to the latest technologies and solutions, ultimately contributing to long-term success in the industry.