Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

The evolution of electrical systems is significantly influenced by innovations in Bus Bars, which have become pivotal in enhancing efficiency and reliability. Recent industry reports indicate that the global Bus Bar market is projected to reach approximately $13 billion by 2026, driven by increasing demand in sectors such as renewable energy, electric vehicles, and efficient power distribution systems. As businesses prioritize energy efficiency and sustainable practices, advances in materials and design of Bus Bars are leading to improved thermal conductivity, reduced weight, and enhanced installation flexibility. With the rising adoption of smart grids and the Internet of Things (IoT) in electrical infrastructure, Bus Bars are set to play an even more critical role in optimizing electrical distribution and management. This exploration delves into the innovations in Bus Bar technology that are shaping the future of electrical systems, ensuring they meet the demands of a rapidly changing energy landscape.

The evolution of bus bars in electrical systems has been significantly influenced by the adoption of innovative materials that enhance conductivity while reducing weight. Traditional copper bus bars, while widely used for their excellent conductivity, can be heavy and costly. Recent studies indicate that the integration of materials such as aluminum and composite plastics is reshaping the landscape. According to a report by Research and Markets, the global bus bar market is expected to grow at a compound annual growth rate (CAGR) of 5.4% from 2021 to 2026, highlighting the increasing demand for lightweight and efficient electrical solutions.

Advanced materials like high-conductivity aluminum alloys are emerging as robust alternatives that deliver comparable performance to copper but at a significantly reduced weight—up to 50% lighter in some cases. This weight reduction not only facilitates easier installation and transport but also contributes to overall energy efficiency within electrical systems. The International Electrotechnical Commission (IEC) emphasizes that innovations in bus bar technology are critical for future applications in renewable energy sectors, such as solar and wind, where space and weight are at a premium. As industries move toward more sustainable practices, these innovative materials are proving to be pivotal in enhancing the effectiveness and efficiency of electrical systems.

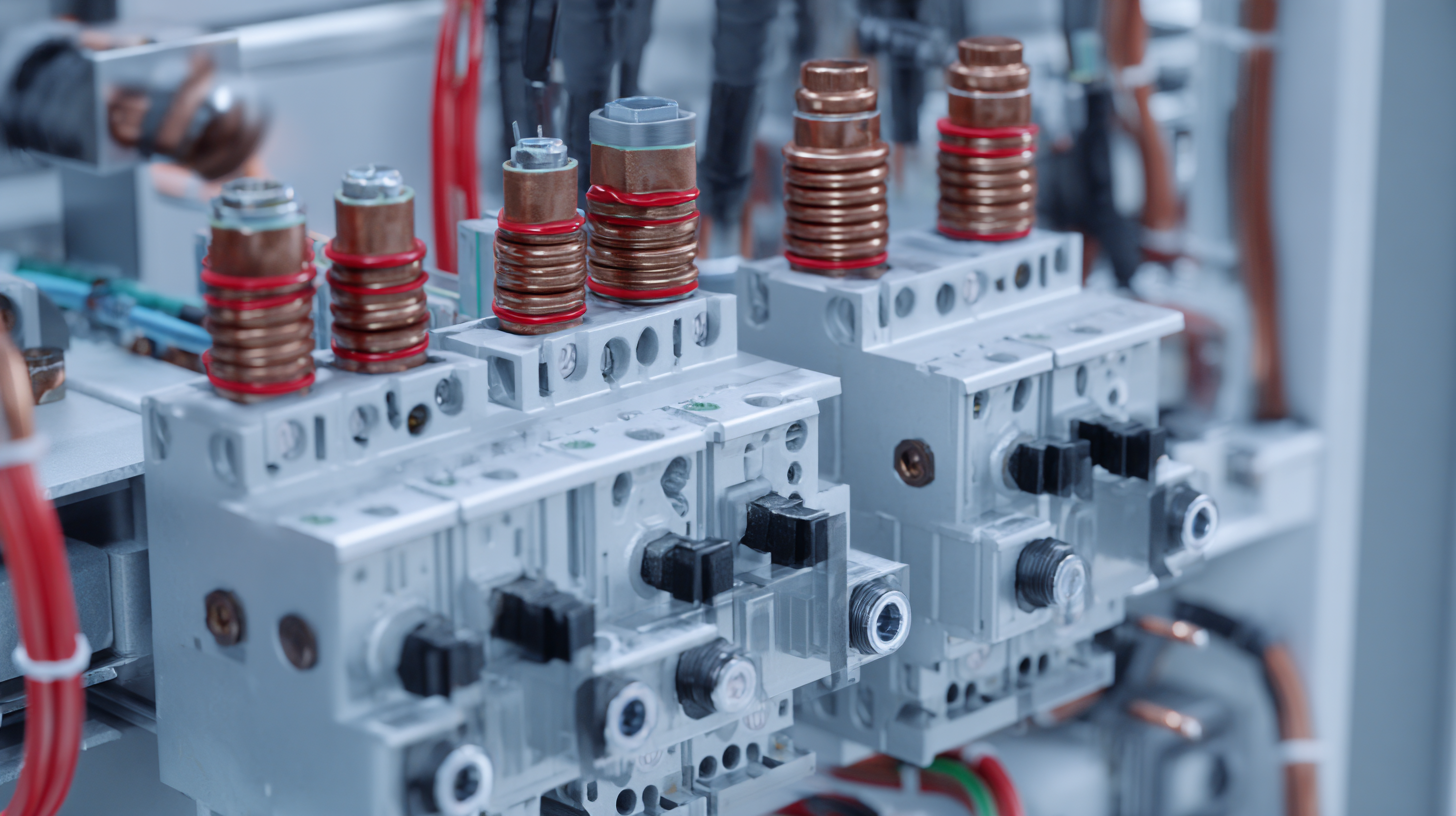

The integration of smart technologies into bus bar systems is revolutionizing how electrical systems are monitored and managed in real-time. Traditionally, bus bars have been critical for distributing electrical power efficiently but often lacked advanced monitoring capabilities. However, the advent of Internet of Things (IoT) devices and artificial intelligence (AI) now allows for continuous data collection and analysis. Sensors embedded within bus bar systems can provide real-time insights into temperature fluctuations, load levels, and overall performance, enabling proactive maintenance and quick response to potential issues.

Furthermore, these smart technologies facilitate better energy management and optimization. By utilizing advanced analytics, operators can identify usage patterns, predict energy demands, and enhance the overall efficiency of the electrical system. For instance, if certain bus bars are identified as underperforming, adjustments can be made to redistribute loads or enhance cooling measures. This not only extends the lifespan of the equipment but also significantly reduces operational costs, making modern electrical systems more robust and reliable while paving the way for smarter and more efficient power distribution networks.

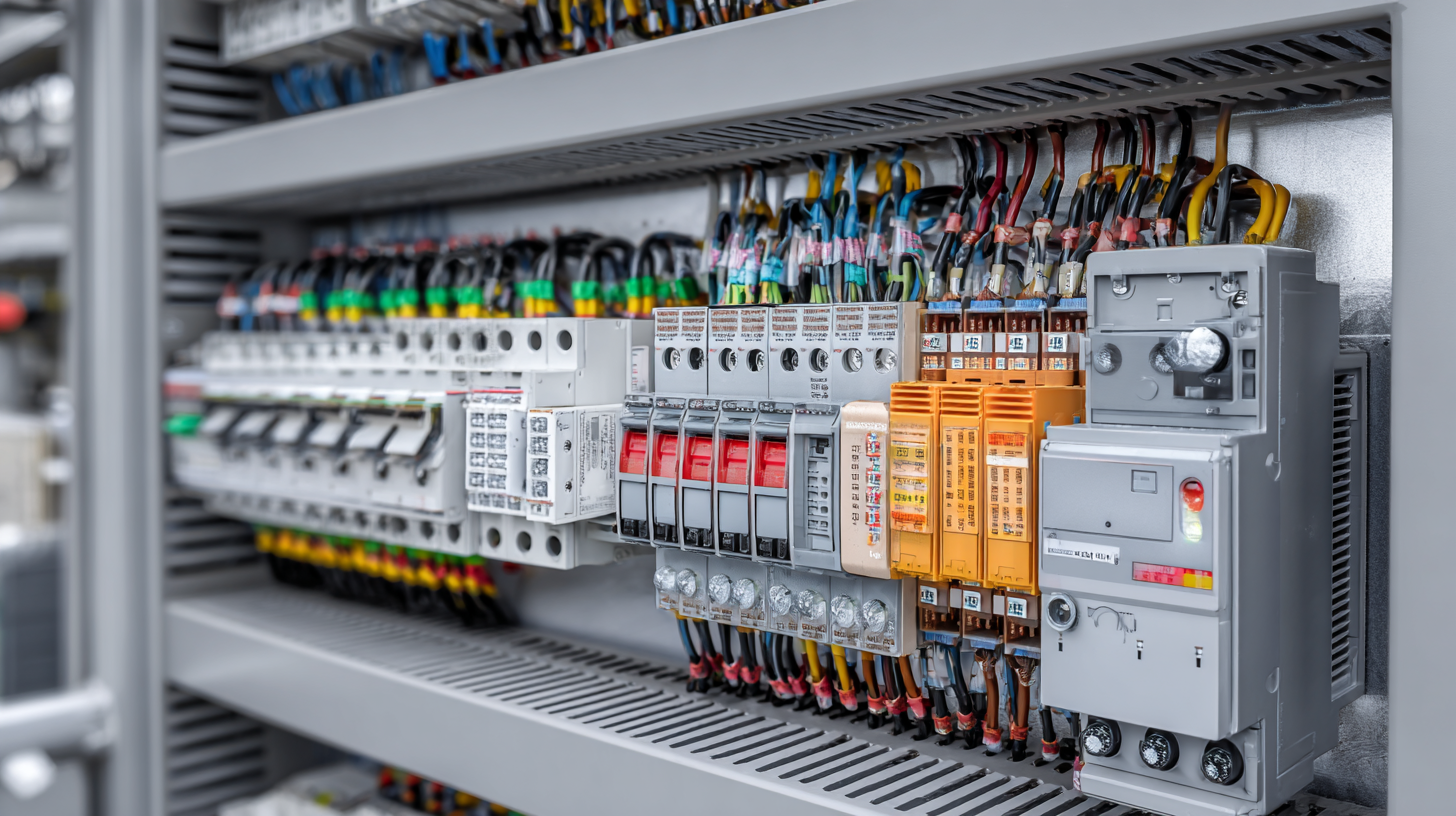

The evolution of electrical systems has led to a significant shift in the design and implementation of bus bars, especially with the emergence of modular bus bars. Traditional bus bars, characterized by their rigid and static structure, often face challenges related to heat dissipation and installation complexity. According to a recent report by MarketsandMarkets, the global bus bar market is expected to grow from USD 19.4 billion in 2021 to USD 27.5 billion by 2026, highlighting the increasing demand for more efficient and adaptable electrical solutions.

Modular bus bars, in contrast, provide a more flexible and scalable approach to electrical distribution. They allow for quick configuration and reconfiguration, catering to the dynamic needs of modern electrical grids. A study from the International Energy Agency (IEA) found that systems utilizing modular bus bar technology can improve energy efficiency by up to 25%, significantly reducing operational costs. Their lightweight design and easier installation also contribute to faster project timelines, making them an attractive choice for both utility companies and infrastructure projects looking to minimize downtime and extend system life.

Bus bars are crucial in modern electrical systems, serving as the backbone for power distribution. As the demand for efficient energy systems grows, manufacturers are exploring advanced production processes that not only enhance performance but also reduce environmental impact. According to a report by MarketsandMarkets, the global bus bar market is expected to reach USD 16.3 billion by 2026, highlighting the industry's shift towards incorporating sustainable practices in manufacturing.

The environmental impact of advanced bus bar manufacturing processes is multifaceted. Traditional methods often involve significant energy consumption and material waste, contributing to carbon emissions. However, innovations such as the adoption of recyclable materials and energy-efficient production techniques can mitigate these effects. A study from the International Energy Agency (IEA) indicates that adopting green manufacturing practices could reduce the carbon footprint of bus bar production by up to 30%. Furthermore, the use of modular bus bar systems can minimize material waste, as they are designed for easy reconfiguration and scalability, thereby extending the product's lifecycle and promoting sustainability in electrical infrastructure.

Investing in these advanced manufacturing processes not only aligns with global sustainability goals but also meets the growing regulatory demands for greener energy solutions. As the industry continues to evolve, it is essential that manufacturers prioritize these innovations to enhance both efficiency and environmental responsibility in electrical systems.

Compact bus bar solutions are set to play a critical role in the evolution of sustainable energy systems. According to a recent report by Grand View Research, the global bus bar market is expected to reach $16.78 billion by 2025, driven by the increasing demand for efficient electrical distribution in industries like renewable energy and electric vehicles. These modern bus bars not only offer space-saving benefits but also provide enhanced thermal management, which is vital in high-power and compact electrical applications.

The integration of compact bus bar solutions facilitates improved energy efficiency and reliability. The International Energy Agency (IEA) predicts that by 2030, electric vehicles will represent 30% of total vehicle sales, necessitating the development of more efficient power distribution systems. Compact bus bars can significantly reduce energy losses and heat generation in these systems, leading to lower operational costs and a smaller carbon footprint. As industries move towards greener technologies, the emphasis on innovation in electrical components like bus bars will be key to supporting a sustainable energy future.

| Aspect | Current Trends | Future Innovations | Impact on Efficiency |

|---|---|---|---|

| Material Used | Copper and Aluminum | Advanced Alloys and Conductive Polymers | Increased conductivity and reduced heat loss |

| Size and Compactness | Standard sizes | Miniaturization Technology | More space efficiency in designs |

| Thermal Management | Basic cooling solutions | Active and Passive Cooling Systems | Enhanced performance and lifespan |

| Integration with Renewable Energy | Limited integration | Smart Bus Bar Systems | Greater synergy with solar/wind technologies |

| Safety Features | Basic safeguards | Enhanced Fault Detection Systems | Reduced risk of failures and accidents |