Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the quest for innovative and efficient electrical solutions, Cast Resin Busbars have emerged as a pivotal technology, offering a reliable and versatile option for modern power distribution systems. As industries evolve and the demand for sustainable and resilient energy infrastructure grows, the exploration of alternative options for Cast Resin Busbars becomes increasingly relevant. This blog delves into the various alternatives available, highlighting their unique benefits and applications. Whether you are considering a switch for performance optimization, environmental impact reduction, or budget considerations, understanding these options can aid in making informed decisions that address diverse needs. Join us as we uncover practical tips and insights to navigate the landscape of Cast Resin Busbars and their alternatives, ensuring that your electrical systems are both efficient and adaptable to future challenges.

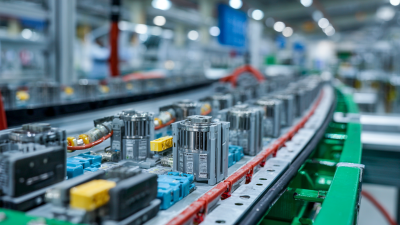

Cast resin busbars are increasingly recognized for their exceptional benefits and versatility in various applications. Unlike traditional busbars, which often use metals like copper or aluminum, cast resin busbars are manufactured using a special resin that offers outstanding electrical insulation properties. This makes them ideal for environments where moisture, dust, and chemicals are present, ensuring reliable operation and a longer lifespan.

Moreover, the applications of cast resin busbars are broad, spanning from industrial settings to commercial buildings. In renewable energy systems, such as solar and wind power installations, these busbars provide efficient power distribution while minimizing energy losses. They are also gaining traction in urban infrastructure projects, where space limitations demand compact and lightweight solutions. By exploring alternative options for cast resin busbars, manufacturers can cater to diverse needs, offering customized solutions that enhance both performance and safety in electrical systems.

In the quest for efficient power distribution, the evolution of busbar production has seen a marked shift towards innovative materials and technologies. Traditional copper and aluminum busbars, while effective, often fall short in terms of weight, durability, and resistance to environmental factors. As the industry searches for alternatives, cast resin materials have emerged as a promising solution. These advanced composites not only offer superior electrical insulation but also exhibit enhanced resistance to corrosion and mechanical stress, making them ideal for diverse applications in harsh environments.

The integration of smart manufacturing technologies in busbar production further amplifies these advantages. Techniques such as additive manufacturing and automation allow for the creation of complex shapes that traditional methods cannot achieve. This flexibility enables the design of lightweight, high-performance busbars that cater to the specific needs of various industries, including renewable energy and electric vehicles. By exploring and implementing these innovative materials and technologies, manufacturers can meet the increasing demand for customized solutions that prioritize efficiency, sustainability, and reliability in power distribution systems.

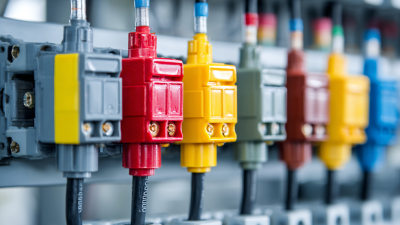

When evaluating busbar options for electrical distribution, a comparative analysis between cast resin busbars and traditional alternatives reveals key differences that cater to various application needs. Cast resin busbars are renowned for their enhanced dielectric properties and resistance to environmental factors. This makes them particularly advantageous in settings where moisture, dust, and corrosive elements are a concern, thereby extending the lifespan and reliability of electrical systems. Their lightweight design also facilitates easier installation and reduced structural support requirements.

In contrast, traditional busbars, often made of copper or aluminum, excel in conductivity and are typically favored for high power applications. However, they can be prone to corrosion and require more frequent maintenance in harsh environments. Additionally, the heat dissipation characteristics of traditional busbars may necessitate additional cooling measures, increasing overall system costs. As industries shift towards more specialized solutions, understanding these distinctions is crucial for selecting the right busbar option to ensure safety, efficiency, and longevity in electrical applications.

| Feature | Cast Resin Busbars | Traditional Busbars |

|---|---|---|

| Material Composition | Epoxy resin, fiberglass | Copper or aluminum |

| Weight | Lighter | Heavier |

| Corrosion Resistance | High | Moderate |

| Insulation Properties | Excellent electrical insulation | Good, but less effective in humid conditions |

| Fire Resistance | High fire resistance | Moderate fire resistance |

| Installation Complexity | Easier installation due to lightweight | More complex due to weight |

| Lifespan | Longer lifespan with reduced degradation | Standard lifespan subject to oxidation |

In today’s ever-evolving industrial landscape, the demand for tailored solutions has never been more critical. Cast resin busbars stand out as a versatile option, but the true potential lies in their customization to meet specific industry requirements. Each sector—be it renewable energy, telecommunications, or manufacturing—has unique electrical characteristics and environmental conditions that necessitate bespoke designs. By leveraging advanced materials and manufacturing techniques, engineers can create busbars that not only fit dimensional specifications but also enhance performance and reliability.

Customization options for cast resin busbars extend beyond mere size adjustments. Manufacturers can incorporate features such as improved insulation properties, enhanced thermal resistance, and corrosion protection depending on the application. For instance, in high-humidity environments, specialized coatings can be applied to ensure longevity and reduce maintenance needs. Furthermore, customizable busbars can facilitate easier installation and integration into existing systems, making them an attractive choice for projects aiming for reduced downtime and increased efficiency. Embracing these tailored approaches allows businesses to optimize their operations while ensuring safety and compliance within their respective industries.

When selecting busbars for electrical systems, sustainability has become a paramount consideration in design and material choice. Traditional materials, while effective, often pose environmental challenges, from resource extraction to end-of-life disposal. As industries shift towards greener practices, exploring alternative options such as cast resin busbars highlights the potential for more sustainable electrical solutions. These options not only reduce the carbon footprint associated with conventional materials but also enhance energy efficiency, resulting in long-term environmental benefits.

Moreover, the design of busbars needs to incorporate eco-friendly practices without compromising performance. Innovative approaches, such as utilizing recycled materials or those that are easily recyclable, help to minimize waste. Additionally, advancements in technology have led to the development of cast resin solutions that are robust and high-performing while being designed for sustainability. The focus on lifecycle assessments further ensures that the environmental impact is considered from production to disposal, making these alternatives relevant not just for immediate functionality but also for future ecological considerations in the electrical industry.