Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the rapidly evolving landscape of modern industries, efficiency and reliability have become paramount. One of the key advancements facilitating these requirements is the adoption of Busbar Electrical systems. These innovative power distribution solutions offer unparalleled advantages, particularly in terms of space efficiency, enhanced safety, and streamlined maintenance. As industries strive to optimize their electrical infrastructures, understanding the core benefits of Busbar Electrical systems becomes essential. This blog will delve into five essential benefits that underscore the importance of Busbar Electrical systems for modern industrial applications, highlighting how this technology is shaping the future of electrical distribution and empowering industries to achieve greater operational excellence.

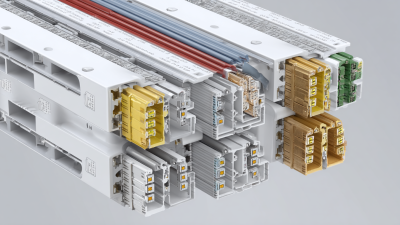

Busbar electrical systems have become a crucial component in modern industrial setups, providing a robust solution for electrical distribution across various applications. These systems utilize conductor materials like copper, aluminum, and various alloys, each offering unique advantages in terms of conductivity, cost, and mechanical strength. The choice of conductor material is often influenced by the specific requirements of the installation, including factors like power rating, environmental conditions, and the nature of the load.

Insulation plays a vital role in the functionality and safety of busbar systems. Depending on the application, options such as air insulation or sandwich insulation can be employed to enhance performance and ensure reliability. Moreover, busbars are categorized based on their power ratings, ranging from low to high power applications, making them versatile for use in residential, commercial, and industrial environments. As industries continue to evolve, the demand for efficient and compact electrical solutions further underscores the necessity of busbar systems in achieving optimal energy management and operational efficiency.

In modern industrial facilities, space efficiency is a critical factor that significantly impacts operational efficiency and cost-effectiveness. Busbar electrical systems offer a compact alternative to traditional wiring methods, allowing organizations to optimize their layout by utilizing vertical and horizontal spaces more effectively. By consolidating electrical distribution into streamlined busbar systems, industries can minimize the footprint of their electrical infrastructure, paving the way for greater design flexibility within manufacturing and processing environments.

Moreover, the reduced space requirement of busbars translates into enhanced safety and accessibility. With fewer cables and connections cluttering the workspace, maintenance personnel can work more efficiently and comfortably, reducing the risk of accidents. The organized nature of busbar installations not only facilitates better airflow and cooling but also contributes to a cleaner environment, allowing for straightforward modifications or expansions in line with evolving industrial needs. Ultimately, the advantages of space efficiency provided by busbar electrical systems play a crucial role in propelling modern industries toward more sustainable and productive futures.

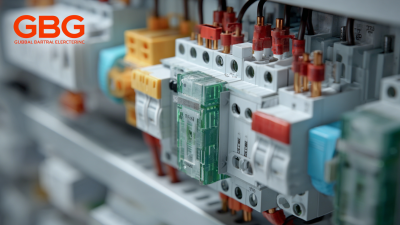

In today’s industrial landscape, the safety of workplace environments is paramount. Busbar electrical systems are revolutionizing how industries enhance safety standards. These systems offer robust electrical distribution, minimizing the risks of electrical faults that can lead to severe hazards. According to a report by the International Electrotechnical Commission (IEC), improper electrical installations account for over 20% of industrial accidents. By implementing busbar systems, industries can considerably reduce these percentages, ensuring a safer working environment.

Utilizing busbar systems allows for efficient heat dissipation and overload management, which are vital for maintaining equipment integrity. A study by the National Fire Protection Association (NFPA) indicates that 25% of electrical fires are linked to overloaded electrical circuits. Busbars can handle higher loads with lower fire risks, thereby protecting both personnel and assets.

**Tip 1:** Regularly monitor and maintain busbar connections to ensure optimal performance and safety.

**Tip 2:** Incorporate thermal imaging technology to identify potential hot spots and prevent overheating in busbar systems.

Implementing these systems not only enhances safety but also contributes to operational efficiency, making them indispensable in modern industries.

Busbar systems are increasingly recognized for their cost-effectiveness in electrical installations across modern industries. According to a report by Research and Markets, busbar trunking systems can save up to 30% in installation costs compared to traditional wiring methods. This significant reduction is due to the simplified design and reduced labor requirements, as busbars can minimize the complexity of interconnections and streamline the installation process.

Furthermore, a study by the International Council on Large Electric Systems (CIGRÉ) highlights that busbar systems also reduce long-term operational costs by improving energy efficiency. With lower resistive losses and better load management, industries using busbars can experience a drop in energy consumption by approximately 15%. This not only translates into decreased energy bills but also contributes to a more sustainable operation in an era where energy efficiency is paramount. By investing in busbar technology, modern industries can achieve significant savings while improving overall performance and reliability.

| Benefit | Description | Cost Reduction (%) |

|---|---|---|

| Simplified Installation | Busbar systems are easier and faster to install compared to traditional wiring, reducing labor costs. | 15% |

| Space Efficiency | Busbars require less physical space, allowing for more efficient use of industrial facilities and reducing overall installation costs. | 10% |

| Reduced Material Costs | Busbar systems use less copper and aluminum compared to traditional cabling, leading to lower material costs. | 20% |

| Lower Maintenance Costs | Busbars require less maintenance over time, translating to savings on service costs. | 25% |

| Enhanced Safety | The design of busbars improves safety, reducing the likelihood of electrical incidents that can incur costs. | 5% |

In the rapidly evolving landscape of modern industries, flexibility and scalability have become critical factors in the design and implementation of electrical systems. Busbar electrical systems offer a versatile solution that adapts seamlessly to varying operational demands. These systems allow for easy modifications and expansions, making them ideal for industries that anticipate growth or changes in production requirements. With busbars, companies can efficiently integrate new technologies and equipment without the need for extensive reconfiguration of existing electrical setups.

Moreover, the modular nature of busbars enhances scalability by enabling industries to expand their electrical capacity as needed. As businesses grow or transition into new markets, busbar systems can be adjusted to accommodate additional loads or more complex distribution needs. This proactive approach not only maximizes space and resources but also reduces downtime associated with upgrades. By leveraging busbar technology, industries can ensure they are poised for future challenges while maintaining operational efficiency and minimizing costs.