Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In recent years, there has been a significant shift towards sustainable electrical infrastructure solutions, with Cast Resin Bus Ducts emerging as a prominent choice in the industry. According to a report by the International Energy Agency (IEA), the demand for energy-efficient electrical systems continues to rise, driven by the need for reducing carbon footprints and enhancing reliability. Cast Resin Bus Ducts offer several advantages, including improved insulation properties and enhanced thermal performance, which not only ensures operational efficiency but also contributes to longer service life. Furthermore, a study by the Energy Research Centre indicates that the implementation of Cast Resin Bus Ducts can lead to energy savings of up to 15% compared to traditional metal bus ducts. This exploration aims to delve deeper into the performance metrics, reliability, and sustainability aspects associated with Cast Resin Bus Ducts, providing a comprehensive understanding of their role in modern electrical systems.

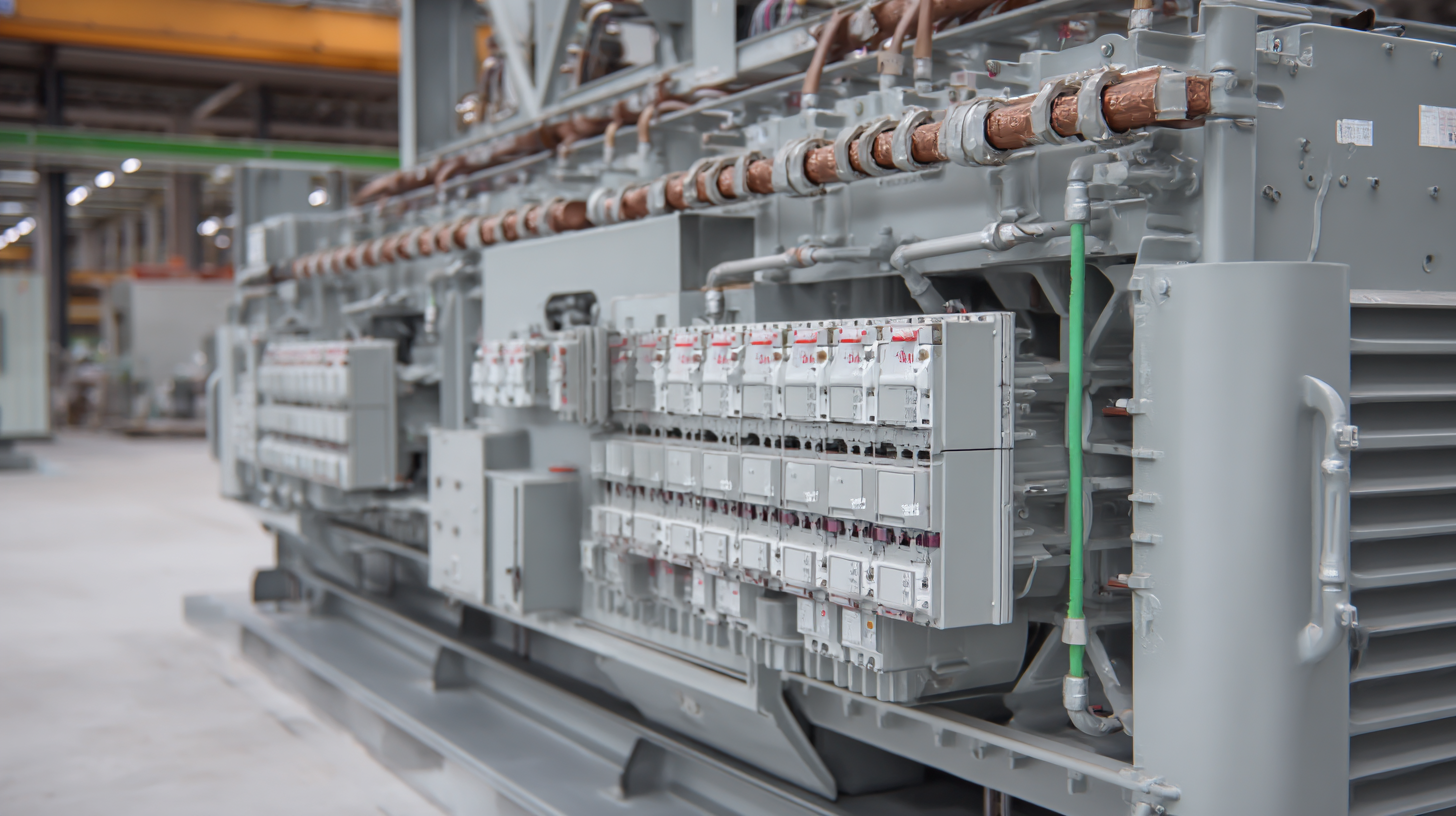

Cast resin bus ducts have gained attention in high-load applications due to their superior thermal performance compared to traditional materials. The unique properties of the cast resin, including its excellent insulation and thermal conductivity, allow these bus ducts to efficiently manage heat generated during peak operations. In environments where electrical loads can fluctuate significantly, maintaining optimal thermal conditions is critical to ensure reliability and extend equipment lifespan.

Testing has shown that cast resin bus ducts can withstand higher temperatures without compromising their structural integrity. This resilience is particularly essential for industries with demanding energy requirements, such as data centers and manufacturing plants. The ability to dissipate heat effectively helps in preventing overheating, which can lead to equipment failure or costly downtimes.

Moreover, the reduced need for additional cooling systems translates to lower energy consumption and a more sustainable operation overall. As businesses focus on reducing their carbon footprint, the adoption of cast resin bus ducts in high-load settings presents a viable solution to enhance both performance and sustainability.

The comparative analysis between cast resin bus ducts and traditional bus ducts reveals significant differences in energy efficiency. Cast resin bus ducts, known for their robust insulation properties, effectively minimize energy losses during power transmission. Their design allows for a reduction in thermal losses, making them a more sustainable option in the long run. This efficiency not only translates to lower operating costs but also contributes to a reduced carbon footprint, aligning with modern energy policies focused on sustainability.

In contrast, traditional bus ducts often rely on metal enclosures that may lack the same level of insulation and efficiency. These systems can experience higher energy losses due to heat dissipation, leading to increased energy consumption and operational expenses. The choice of materials in traditional designs can also contribute to environmental concerns, as they may not utilize sustainable resources. Overall, the evaluation emphasizes that cast resin bus ducts present a superior alternative, combining enhanced performance with a commitment to sustainable practices in energy management.

The lifecycle sustainability of cast resin bus ducts is a critical consideration in today's industrial landscape. As organizations strive to minimize their carbon footprint, understanding the environmental impact of electrical systems is essential. Cast resin bus ducts offer several advantages, including lower emissions during production and operation, making them a preferable choice for sustainable energy solutions. Their durable nature not only extends their lifespan but also reduces the need for frequent replacements, further decreasing resource consumption and waste.

Tips: When evaluating bus duct systems, consider their material composition and manufacturing processes. Opting for manufacturers that prioritize eco-friendly practices can significantly enhance your project's sustainability. Additionally, regular maintenance and inspections can prolong the lifespan of these systems, indirectly contributing to lower carbon emissions associated with production and waste.

Moreover, the transition to cast resin bus ducts can lead to reduced energy losses compared to traditional alternatives. By insulating effectively and minimizing heat generation, these ducts contribute to better energy efficiency, which in turn translates to a smaller carbon footprint over time. Prioritizing energy-efficient solutions not only benefits the environment but also helps organizations save on operational costs in the long run.

When considering the installation of electrical systems, cast resin bus ducts stand out not only for their performance but also for their cost efficiency in maintenance and installation. According to a report by the International Electrotechnical Commission, cast resin bus ducts typically last longer than traditional alternatives, reducing the need for frequent replacements. This longevity translates to lower long-term costs—an estimated 20-30% reduction in maintenance expenditures over a 20-year lifecycle.

**Tip:** When planning your installation, consider the initial savings from reduced downtime and maintenance, as this can significantly impact overall cost-effectiveness.

Moreover, the installation process for cast resin bus ducts requires less labor and time compared to conventional systems. A recent study by the Institute of Electrical and Electronics Engineers (IEEE) found that installers can complete the setup of cast resin duct systems in about 15-20% less time, thanks to their lightweight and modular design. This not only enhances project timelines but also minimizes associated labor costs.

**Tip:** Ensure your technical team is adequately trained on cast resin installations to leverage these time efficiencies fully.

By investing in cast resin bus ducts, industries can enjoy enhanced performance while benefiting from significant long-term savings, reinforcing their position as a sustainable choice in modern electrical infrastructure.

The advancement of cast resin technology has significantly enhanced the performance and durability of dry-type transformers, a crucial development in the electrical distribution sector. According to industry reports, the global dry-type transformer market is projected to grow at a CAGR of around 6% from 2023 to 2030, driven primarily by the increasing demand for energy-efficient and sustainable solutions.

Cast resin transformers, known for their robust insulation properties and resistance to harsh environments, are becoming increasingly popular in urban infrastructure and renewable energy applications.

Innovative improvements in cast resin technology focus on enhancing operational efficiency and lifecycle sustainability. The introduction of high-performance materials has led to transformers that can withstand higher temperatures and offer better protection against moisture and contaminants. Reports indicate that cast resin transformers have a lifespan exceeding 30 years, significantly reducing the need for replacements, thereby minimizing waste and environmental impact. Moreover, as industries shift toward greener alternatives, the adoption of cast resin bus ducts becomes pivotal, reflecting the industry's commitment to sustainable practices while ensuring reliability in power distribution systems.