Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

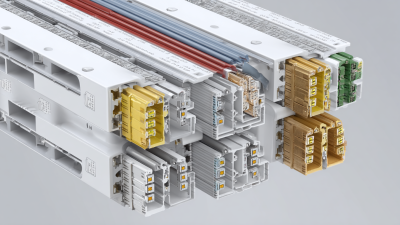

In today's increasingly electrified world, Busbar Distribution systems have gained substantial traction in commercial and industrial settings due to their high efficiency, space-saving design, and reduced installation costs. According to a report by the International Electrotechnical Commission (IEC), the global demand for busbar trunking systems is projected to reach $1.9 billion by 2026, highlighting their critical role in modern electrical distribution.

However, despite their advantages, these systems are not without challenges. Common issues such as thermal overload, poor connectivity, and maintenance difficulties can significantly impact system performance and reliability. Understanding these issues is essential for optimizing Busbar Distribution and ensuring uninterrupted power supply, which is a cornerstone of operational efficiency in today’s fast-paced environments.

Busbar distribution systems are critical components in modern electrical infrastructure, yet they often face several common issues that can significantly impact their performance. One of the prevalent problems includes overheating, which occurs due to inadequate sizing, poor connections, or overloading. When busbars operate at elevated temperatures, the efficiency of the electrical system diminishes, and there is an increased risk of failure, leading to costly downtime and repairs.

Another common issue is corrosion, particularly in environments with high humidity or pollutants. Corrosion can degrade the conductive materials, resulting in higher resistance and heat generation, further exacerbating the overheating issue. Regular maintenance and monitoring are essential to mitigate these risks. Additionally, improper installation can lead to misalignment, which creates hotspots and increases the likelihood of short circuits. Addressing these concerns through preventive measures and employing quality materials can enhance the reliability and longevity of busbar distribution systems, ensuring they operate at optimal performance levels.

Electrical overloading in busbar configurations is a critical issue that can lead to severe consequences for both equipment and system reliability. The primary cause of overloading is often an increase in electrical demand that exceeds the busbar’s rated capacity. This can occur in commercial and industrial settings where operational loads fluctuate significantly. Additionally, faulty design or improper maintenance may also contribute to overloading, as underestimating demand can lead to insufficient capacity being allocated to manage peak loads effectively.

The consequences of electrical overloading can be detrimental. Overloaded busbars can operate at elevated temperatures, leading to insulation degradation and potential failure of electrical components. This not only poses a risk of downtime and expensive repairs but also increases the likelihood of fire hazards. Furthermore, frequent overloading can cause excessive wear on the system, ultimately shortening the lifespan of the busbar and connected equipment. Therefore, it is crucial for engineers and facility managers to carefully monitor loads and implement robust design practices to mitigate the risk of electrical overloading in busbar distribution systems.

Thermal management is a critical aspect of busbar distribution systems, as heat generated during operation can significantly affect performance and safety. As current flows through the busbars, resistive losses convert electrical energy into heat, which can lead to overheating. This phenomenon not only decreases efficiency but also risks damaging components, reducing the system's lifespan. Thus, effective thermal management strategies are essential for ensuring reliable operation.

To address these challenges, various solutions can be implemented. One effective approach involves utilizing materials with high thermal conductivity for busbar construction, allowing for better heat dissipation. Additionally, incorporating heat sinks or fans can enhance cooling in high-load scenarios. Advanced monitoring systems can also play a vital role in thermal management by providing real-time temperature data, allowing for proactive adjustments to the system.

By combining these strategies, busbar distribution systems can maintain optimal performance while minimizing the risks associated with thermal issues.

Corrosion and material degradation are critical issues in busbar distribution networks that can lead to significant operational failures and safety hazards. Studies indicate that corrosion can reduce the life expectancy of busbars by up to 30%, impacting their conductivity and overall performance. A report from the International Electrotechnical Commission highlights that over 20% of electrical faults in industrial settings are attributed to degraded busbar systems. The presence of moisture, pollutants, and temperature fluctuations exacerbates these risks, leading to increased maintenance costs and unexpected downtimes.

**Tips:** Regular inspections are essential; ensure busbars are cleaned and free from any corrosion-inducing contaminants. Consider using protective coatings or corrossion-resistant materials, which can extend the lifespan of the system significantly. Additionally, maintaining optimal environmental conditions in distribution areas can mitigate the risk of degradation.

In addition to corrosion, thermal fatigue also poses a considerable threat to busbars. The expansion and contraction of materials during thermal cycles can result in micro-cracks that compromise conductivity and mechanical integrity. According to a study by the IEEE, approximately 15% of unplanned outages in electrical distribution networks can be traced back to thermal-related failures. Keeping busbars properly torqued and ensuring adequate ventilation can help alleviate these issues.

**Tips:** Implement a regular thermal imaging inspection program; this helps identify hot spots that may indicate developing issues. Consistently monitor load levels to prevent overheating and ensure that your busbar system operates well within its thermal capacity.

Maintaining busbar distribution systems is crucial to ensure their efficiency and longevity. Regular inspections can help identify potential issues before they escalate into major failures. A systematic approach can aid in spotting corrosion, overheating, and loose connections, all of which are common culprits in busbar systems. Implementing routine thermal imaging scans can reveal hotspots that may indicate electrical imbalances or inadequate connections.

Tip: Schedule thorough inspections at least twice a year to maintain optimal performance. Use advanced diagnostic tools to catch issues early—this proactive maintenance can save considerable costs in the long run.

In addition to inspections, proper cleaning routines are vital. Dust and grime accumulation can impede performance, so it’s important to keep busbars clean. Utilize non-abrasive materials and ensure power is disconnected during cleaning to prevent electrical shock.

Tip: Implement a cleaning schedule that aligns with your inspection timeline to make efficiency a priority. Educating staff on the correct cleaning procedures and the importance of maintenance best practices can also reduce risks significantly.