Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

Choosing the right lighting busbar for your electrical system is crucial for ensuring both functionality and safety. According to electrical systems expert John Anderson, "The efficiency of your lighting system heavily relies on the quality and suitability of your busbar." With a plethora of options available in the market, understanding the various factors that influence your selection is essential for optimal performance.

A lighting busbar acts as a vital conduit in electrical systems, distributing power efficiently and enabling seamless operation of lighting fixtures. As the demand for energy-efficient solutions grows, so does the complexity of these systems. Therefore, professionals must consider elements such as load capacity, installation environment, and compatibility with existing infrastructure. Making informed choices regarding your lighting busbar can lead to enhanced performance, reduced energy costs, and increased longevity of your electrical installations.

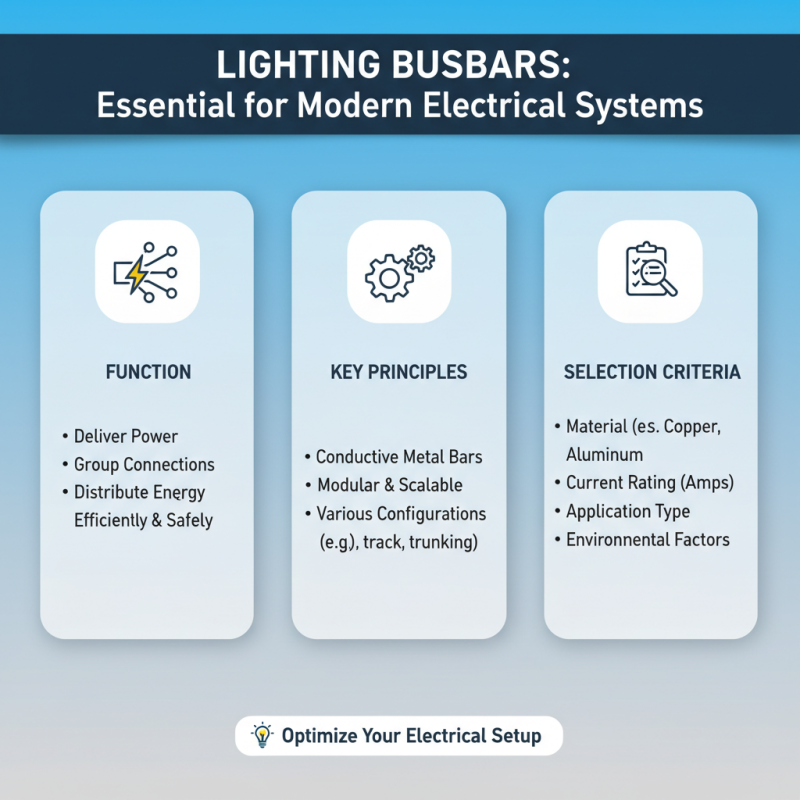

Lighting busbars are crucial components in modern electrical systems, providing a reliable means to deliver power to various lighting fixtures and equipment. These conductive metal bars are designed to group connections and distribute electrical energy with efficiency and safety. Understanding the basic principles behind lighting busbars is essential for selecting the right one for specific applications, as they can come in various configurations, materials, and current ratings.

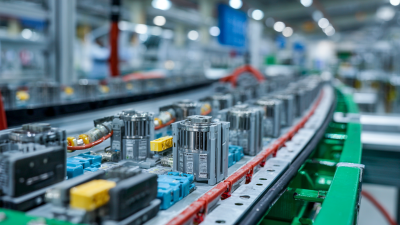

The primary application of lighting busbars is found in commercial and industrial environments where high power demands necessitate optimal energy distribution. They facilitate easy installation and maintenance, reducing the complexity often associated with traditional wiring methods. Furthermore, busbars allow for scalability, as additional lighting systems can be integrated without significant alterations to existing infrastructure. Factors such as load capacity, environmental conditions, and compatibility with existing systems should be carefully considered to ensure that the chosen busbar enhances overall electrical performance while maintaining safety standards.

When selecting the right lighting busbar for your electrical system, several key factors must be taken into account to ensure efficiency and safety. First, consider the current carrying capacity, which is critical for determining how much power your lighting setup will require. According to the International Electrotechnical Commission (IEC) standards, the current rating of a busbar system should be adequately matched with the anticipated load to prevent overheating and potential failure. Generally, a safety margin of 20-30% above the maximum load is recommended to accommodate unforeseen changes in power consumption.

Another important factor is the environmental conditions where the busbar will be installed. Whether in an indoor environment or exposed to the elements, the choice of material and protection standards is vital. A report from the National Fire Protection Association (NFPA) indicates that over 20% of electrical fires are caused by faulty wiring or inadequate connections, underscoring the significance of selecting a busbar with appropriate insulation and weather resistance ratings. Additionally, the layout of the electrical system, including the length of runs and the number of connections, can influence the choice of busbar configuration, impacting both installation complexity and maintenance needs.

| Key Factors | Description | Recommended Specifications | Considerations |

|---|---|---|---|

| Load Capacity | Determine the total load that the lighting systems will draw. | Ensure busbar can handle 20% more than the calculated load. | Future expansion might require higher capacity. |

| Material | Common materials include copper and aluminum. | Copper for lower resistance; aluminum for cost-effectiveness. | Consider corrosion resistance based on environment. |

| Physical Size | Space available for installation | Select a compact design while accommodating required load. | Plan for maintenance access and airflow around busbars. |

| Current Rating | The maximum current the busbar can carry. | Choose a busbar rated at least 10% higher than expected current. | Consider potential load increases and peak currents. |

| Insulation Type | Insulation protects against electrical shorts and environmental factors. | Select insulation rated for voltage levels and environments. | Consider heat dissipation and environmental exposure. |

When selecting the appropriate lighting busbar for an electrical system, it is essential to understand the different types available on the market. Lighting busbars are typically categorized into three main types: copper, aluminum, and composite. Copper busbars are known for their excellent conductivity and durability, making them suitable for high-load applications. According to a report by the International Copper Association, copper busbars can achieve a conductivity rate of up to 95%, leading to lower energy loss and improved efficiency in electrical systems.

On the other hand, aluminum busbars present a lightweight alternative, which can significantly reduce installation costs, especially in large-scale projects. They are often favored for their corrosion resistance and lower material costs, as outlined in a study by the Aluminum Association, which emphasizes that for straightforward installations requiring less heavy-duty specifications, aluminum can be more economical while still providing adequate performance. Furthermore, composite busbars are emerging as a hybrid solution that combines the benefits of both materials, offering enhanced insulation properties and flexibility in installation, while supporting modern demands for sustainability in electrical infrastructure.

Understanding the specifications and performance characteristics of these busbar types is crucial for optimizing electrical systems. Factors such as load capacity, installation environment, and potential thermal expansion must be considered to ensure a reliable and efficient lighting solution. As the industry evolves, the adoption of innovative materials and designs continues to reshape how lighting busbars are utilized, further enhancing system performance and energy efficiency.

When selecting the right lighting busbar for your electrical system, durability is a critical factor that cannot be overlooked. The materials used in the construction of busbars play a significant role in their overall performance and longevity. Commonly used materials include copper and aluminum, each offering distinct advantages.

Copper, known for its excellent conductivity, provides higher efficiency and lower energy losses. However, it can be more expensive and heavier compared to aluminum, which, while less conductive, is lighter and more cost-effective. Evaluating the specific requirements of your electrical system will help determine the most suitable material for your busbar.

In addition to material choice, the design of the busbar is essential for ensuring durability. Factors such as thermal expansion, environmental resistance, and mechanical strength all influence the lifespan of the busbar. A well-designed busbar should have appropriate insulation to withstand temperature variations and moisture, thereby preventing corrosion. Moreover, robust mechanical designs that accommodate thermal expansion can prevent deformation in high-load situations. By carefully assessing these material and design considerations, you can select a lighting busbar that ensures reliability and performance in your electrical system.

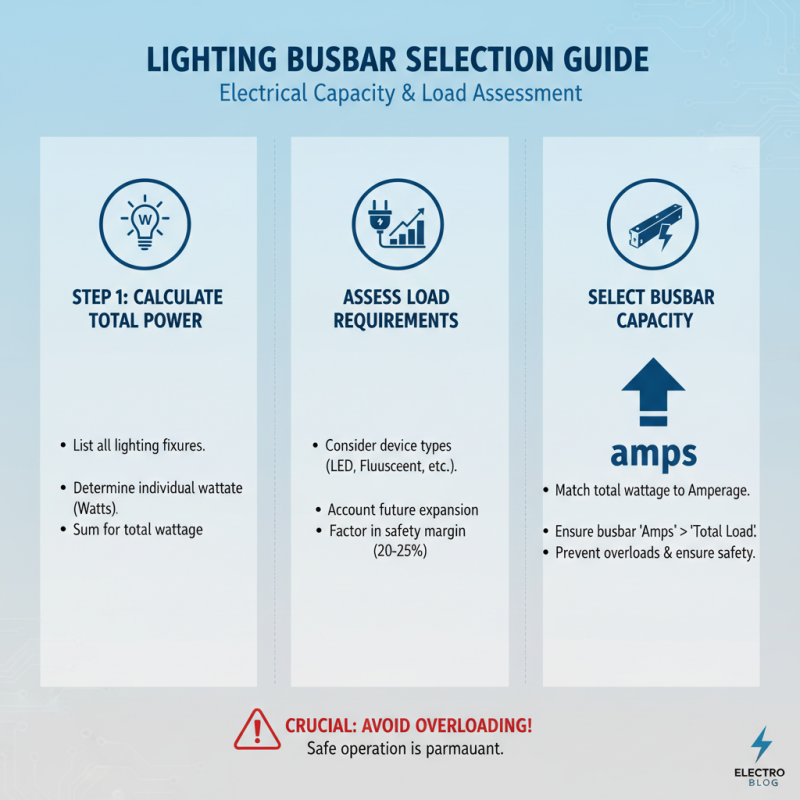

When selecting the appropriate lighting busbar for your electrical system, it is crucial to accurately assess the electrical capacity and load requirements. First, determine the total power consumption of all lighting fixtures and other connected devices. Calculating the wattage demands will allow you to identify the necessary capacity of the busbar, which is essential for ensuring safe operation and avoiding potential overloads. Keep in mind that different types of lighting sources may have different power requirements, and this should be considered when evaluating the overall load.

Additionally, consider the diversity factor in your calculations, which accounts for the fact that not all lighting may be used simultaneously. By using this factor, you can make a more educated estimate of your system's overall load while ensuring that your busbar can handle the peak demands during high usage periods. Once you have a clear understanding of your electrical capacity needs and load requirements, you will be better equipped to select a busbar that meets those specifications, ensuring both performance and safety in your lighting system.