Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

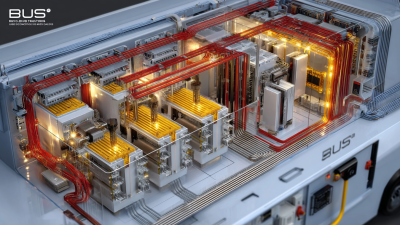

When embarking on an electrical project, one of the critical decisions involves selecting the appropriate Bus Duct Electrical system. This system plays a pivotal role in distributing electrical power efficiently and safely within various infrastructures, from industrial facilities to commercial buildings. The right choice can significantly enhance performance, reduce installation time, and minimize maintenance costs, ultimately leading to a more reliable power supply.

Understanding the different types of Bus Duct Electrical options available, including their designs, capacities, and installation requirements, is essential for project success. Factors such as the specific electrical load demands, environmental conditions, and future scalability must be carefully considered to ensure optimal functionality. Moreover, integrating the right Bus Duct Electrical system can lead to improved energy efficiency and safety measures, aligning with modern sustainability goals.

In this article, we will guide you through the key considerations and steps to selecting the right Bus Duct Electrical system tailored to your project's unique needs. By examining essential criteria and highlighting best practices, we aim to equip you with the knowledge necessary for making informed decisions that will contribute to the long-term success of your electrical installations.

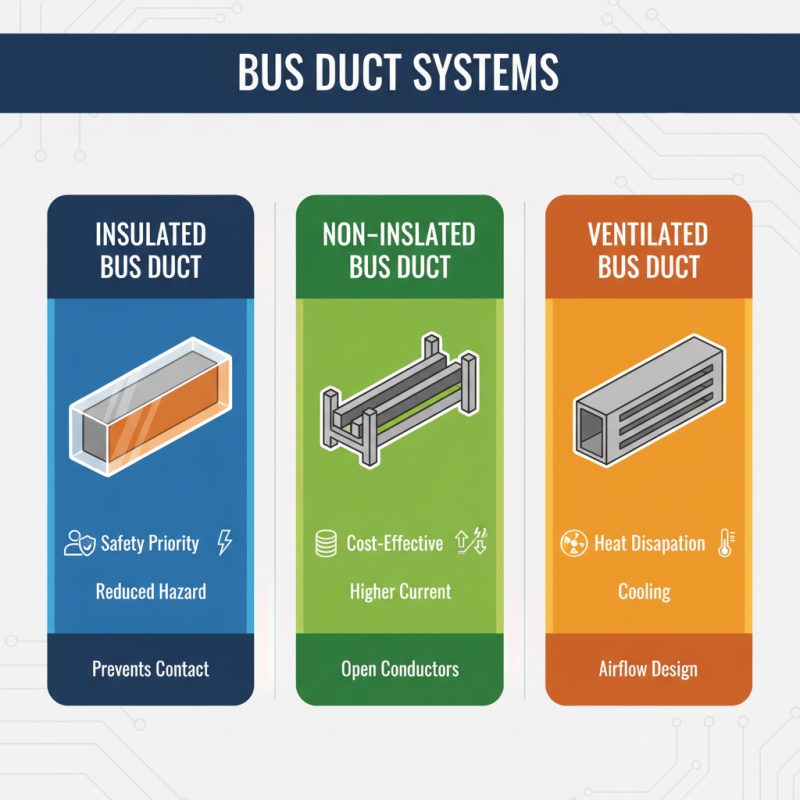

Bus duct systems are vital components in electrical distribution, providing a convenient and efficient means to transfer power in various industrial and commercial settings. These systems mainly come in three types: insulated bus ducts, non-insulated bus ducts, and ventilated bus ducts. Insulated bus ducts are encased in a material that prevents accidental contact and reduces the risk of electrical hazards, making them ideal for environments where safety is a priority. Non-insulated bus ducts, while requiring more careful placement to avoid contact, can carry higher currents efficiently and are often chosen for their cost-effectiveness in large installations.

The applications of bus duct systems are diverse, ranging from large manufacturing plants to office buildings and data centers. In industrial settings, insulated bus ducts are frequently utilized due to their robustness and ability to withstand demanding conditions. In contrast, non-insulated bus ducts might be employed in spaces where airflow and thermal management are crucial, as they allow for natural ventilation. Ventilated bus ducts are specially designed to dissipate heat effectively, making them suitable for high-power applications. Selecting the appropriate type of bus duct system involves considering factors such as space constraints, environmental conditions, and specific electrical load requirements.

When selecting a bus duct electrical system for your project, there are several key factors that must be carefully evaluated to ensure reliability, efficiency, and safety. First and foremost, consider the load requirements of your application. It's essential to assess the current carrying capacity and future expansion needs to determine the appropriate size and configuration. Additionally, ensure that the selected system can handle the environmental conditions it will face, such as temperature fluctuations, humidity, and potential exposure to corrosive elements.

Another critical factor is the installation and maintenance process. Opt for a bus duct that offers straightforward installation, minimizing labor costs and time delays. Accessibility for future maintenance is equally important; a well-designed system allows for easy inspection and servicing without disrupting the entire setup.

Tips: When analyzing your options, make use of simulation tools to forecast performance under different loads. Furthermore, consult with industry professionals to gather insights into the best practices associated with bus duct systems. Remember, the long-term performance and operational efficiency of your facility depend significantly on making the right choice today.

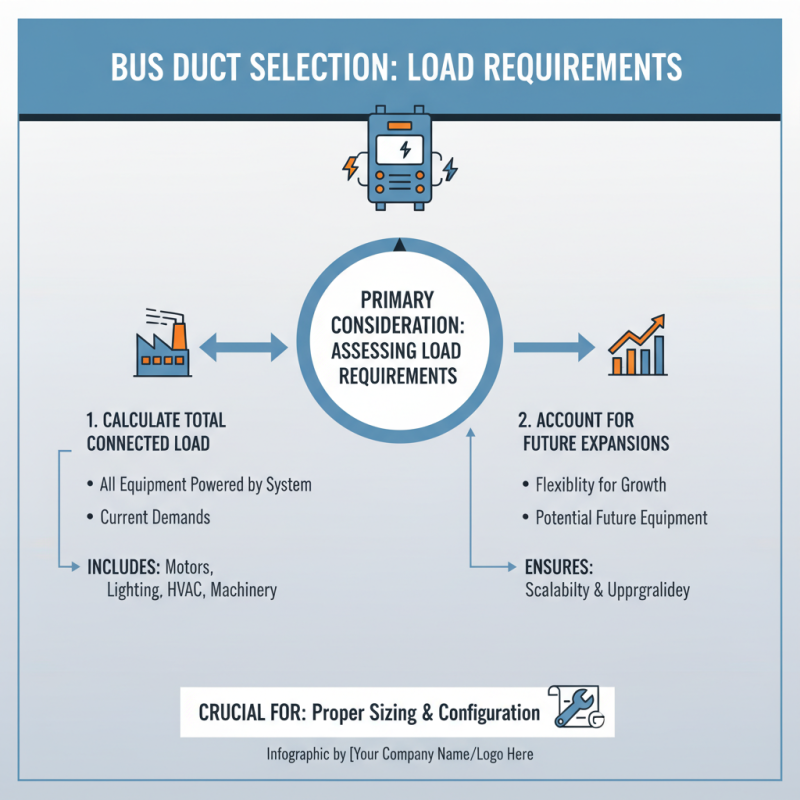

When selecting a bus duct electrical system for your project, one of the primary considerations lies in assessing the load requirements. Understanding the electrical load that your system will need to support is crucial in determining the appropriate size and configuration of the bus duct. Start by calculating the total connected load, which includes all equipment that will be powered by the system, as well as any potential future expansions. This not only ensures that the system can handle the current demands but also provides flexibility for future growth.

Additionally, it is important to account for load distribution across the bus duct. Different areas within the facility may have varying power requirements, and consequently, careful planning is needed to balance these loads effectively. This involves evaluating the peak load conditions and considering any transient load situations that might occur during operation. By accurately assessing and documenting these load requirements, you can select a bus duct system that is both efficient and reliable, ultimately enhancing the performance of your electrical infrastructure.

When selecting the right bus duct electrical system for your project, a thorough evaluation of the installation space and environmental conditions is crucial. The physical dimensions of the installation area will dictate the size and type of bus duct to be used. For instance, if the installation space is confined, a compact bus duct system may be necessary. According to industry research, optimal space utilization can improve overall system efficiency by up to 15%. It's essential to assess the ceiling height, access for maintenance, and potential obstacles such as piping or ductwork when planning your installation.

Environmental conditions play a significant role in determining the suitable bus duct system as well. Factors such as temperature fluctuations, humidity levels, and exposure to dust or corrosive substances must be considered. Reports indicate that systems exposed to harsh environments, such as coastal areas with high salinity, may need additional protective coatings or specialized materials, which can enhance durability and performance. Regular evaluations of these conditions can prevent unexpected failures, as a staggering 30% of premature electrical failures are linked to environmental stressors.

Tips: Always consult with an electrical engineer to ensure that your bus duct system not only meets the design requirements but also aligns with local regulations and safety standards. Furthermore, consider future expansion needs during the planning phase, which can save time and costs down the road. Investing in a comprehensive site evaluation prior to installation can lead to more informed decisions and ultimately a more reliable electrical distribution system.

| Criteria | Considerations | Recommended Specifications |

|---|---|---|

| Installation Space | Available ceiling height and floor area | Minimum clearance of 12 inches; width vs. height ratio 1:3 |

| Environmental Conditions | Temperature and humidity levels | Operating temp range: -20°C to +50°C; humidity < 95% |

| Load Type | Type of application (light, medium, heavy) | Heavy loads require higher amp ratings (up to 5000A) |

| Future Expansion | Anticipated growth in power needs | Choose a system that can support an additional 25% load |

| Safety Standards | Compliance with local and national codes | Must meet NEC standards and any additional local codes |

When budgeting for a bus duct electrical system, it is essential to consider several factors that can significantly impact overall costs. The initial investment will include materials and installation. Bus ducts typically require high-quality conductive materials, which can vary in price based on the system's specifications and capacity. It's advisable to obtain quotes from multiple suppliers to ensure you're receiving the best value for materials, as well as to weigh the benefits of various design configurations that might affect performance and durability.

In addition to material costs, labor expenses are a crucial consideration. Installation complexity will influence labor rates, so understanding the project's scope beforehand can help in accurate budgeting. Engaging experienced professionals can mitigate risks and potentially reduce long-term costs associated with maintenance and troubleshooting.

Lastly, it's important to factor in any potential future scalability in the planning stages. While initial costs may seem higher, investing in a system designed for growth can provide financial benefits down the line, as it minimizes the need for extensive modifications or complete overhauls as project demands evolve.

By carefully evaluating these cost components, you can make an informed decision that best aligns with your project's financial constraints and goals.