Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

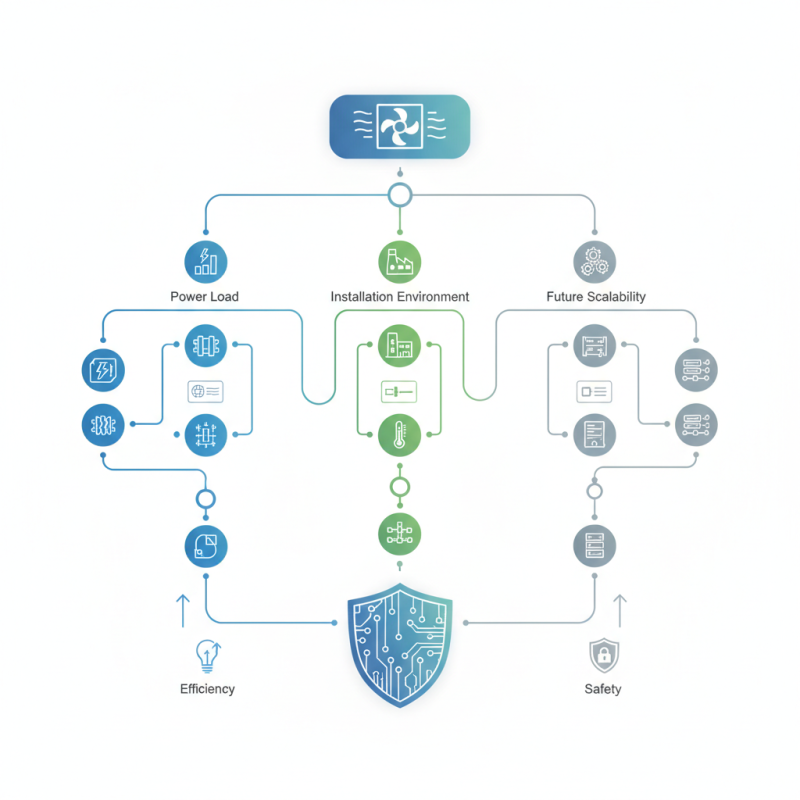

When it comes to designing an efficient electrical system, the choice of busway is crucial. This is especially true for the Air Type Busway, which offers unique advantages in terms of cooling and power distribution. According to John Doe, a leading expert in the busway industry, "Selecting the right Air Type Busway is essential for optimizing electrical performance and ensuring long-term reliability." His insight underscores the importance of understanding the specific needs of your electrical system to make an informed decision.

The Air Type Busway is designed to provide superior airflow and cooling capabilities, making it a popular choice for applications where heat dissipation is a priority. As facilities increasingly rely on complex electrical systems, the demand for efficient and adaptable solutions like Air Type Busway continues to rise. By evaluating factors such as power load, installation environment, and future scalability, designers can select the most suitable busway to enhance system efficiency and safety.

In this article, we will explore the critical considerations when choosing the right Air Type Busway for your electrical system needs. Through expert analysis and practical insights, we aim to equip you with the knowledge required to make the best choice for your specific application, ensuring optimal performance and longevity in your electrical setup.

Air type busways are essential components in electrical distribution systems, providing efficient and flexible solutions for power transmission. Unlike traditional busbars that utilize solid metal conductors, air type busways leverage the natural insulating properties of air, allowing for reduced weight and streamlined installation. They are particularly beneficial in applications where space is a premium, as their modular design enables easy reconfiguration and expansion to accommodate changing electrical loads.

Understanding the basic structure and function of air type busways is crucial for selecting the right system for specific needs. These busways consist of a series of insulated conductive channels that facilitate the flow of electricity while minimizing losses. Their applications range from industrial environments to commercial buildings, supporting various electrical equipment such as transformers, switchgear, and motor control centers. By comprehending the operational principles and advantages of air type busways, engineers and facility managers can make informed decisions that enhance system reliability and performance.

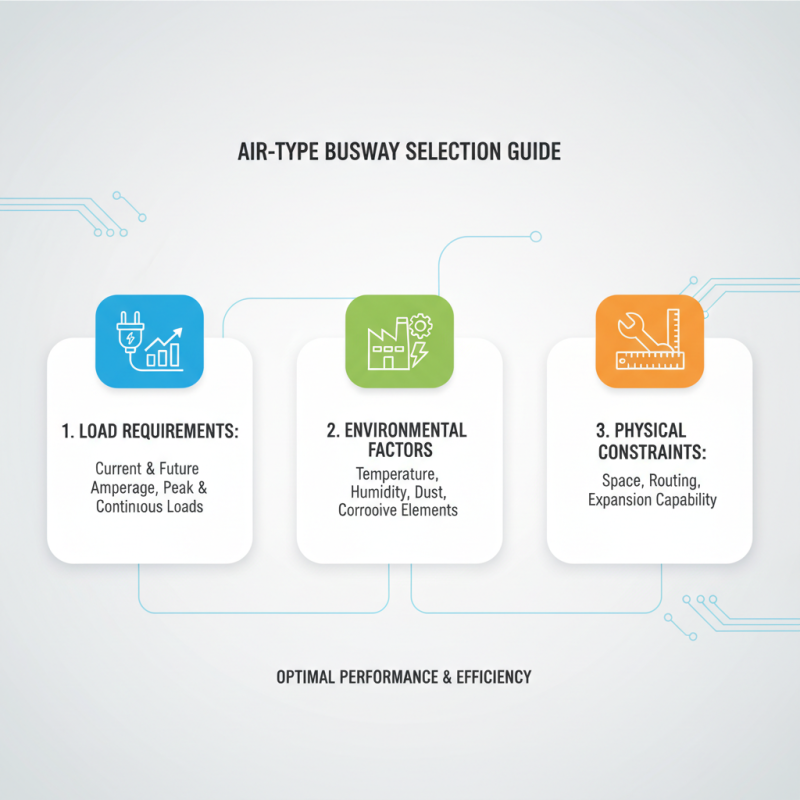

When selecting an air type busway for your electrical system needs, several key factors should be considered to ensure optimal performance and efficiency. First, it's important to assess the current and future load requirements of your electrical system. This involves evaluating the total amperage that will flow through the busway throughout its expected lifespan. Understanding both peak and continuous loads will help in determining the appropriate size and configuration of the busway needed to handle the demands without overheating or failing.

Another critical factor is the environmental conditions in which the busway will be installed. Consideration should be given to the ambient temperature, humidity, and potential exposure to dust or moisture. Air type busways must be designed with materials and features that can withstand these conditions, ensuring reliable operation over time. Additionally, the layout and installation space available will influence your choice; flexibility in design can ease installation and maintenance requirements, making it essential to select a busway that fits well within your allocated space while allowing for easy access during service.

When evaluating the specifications of different air type busway models, it is crucial to consider several critical parameters that will impact the performance and efficiency of your electrical system. One of the primary specifications to examine is the current rating, typically expressed in amperes (A). Most air type busway systems come with ratings that can range from 100 A to over 5000 A, allowing for versatility in accommodating various power needs. According to a recent industry report, systems designed to handle higher current loads demonstrate improved efficiency and reduced heat losses, optimizing overall operational costs.

Another essential specification is the mechanical strength and environmental ratings of the busway. Air type busways are often subjected to varying environmental conditions, and their resilience is evaluated through standards such as NEMA ratings. Systems with a higher NEMA rating will typically offer better protection against dust, moisture, and other environmental factors, enhancing longevity and reliability. Notably, the IEEE 141 standard emphasizes the importance of these ratings to ensure safety and effectiveness in industrial applications, where maintaining uninterrupted power supply is critical.

Additionally, the thermal management capabilities of air type busways should not be overlooked. Effective heat dissipation is fundamental to avoid overheating, which can lead to performance degradation and system failure. In a study published by the Electrical Power Research Institute, it was highlighted that air type busways equipped with optimal heat sink designs can reduce operational temperatures by up to 20%. This not only extends the lifespan of the busway but also supports better overall system reliability, making it an essential consideration during the selection process.

When selecting the appropriate Air Type Busway for your electrical system, it’s crucial to assess its compatibility with your existing infrastructure. According to a report by the Electric Power Research Institute (EPRI), nearly 30% of electrical system failures can be traced back to improper integration of busway systems. This statistic underscores the importance of ensuring that the busway you choose can effectively work with your current power distribution configuration. Key factors such as load requirements, environmental conditions, and installation space should be evaluated to avoid any potential conflicts that may arise due to system inadequacies.

In addition, thermal management is a significant consideration when assessing compatibility. The Institute of Electrical and Electronics Engineers (IEEE) recommends that busway systems should maintain a temperature rise of no more than 30°C over ambient conditions to ensure optimal performance. If your electrical system has high load fluctuations, opting for a busway with enhanced cooling capabilities can mitigate the risk of overheating and extend the system's longevity. Understanding the thermal characteristics and load-handling capabilities of different air type busways will allow you to make a more informed decision that aligns with your operational requirements and improves overall reliability.

| Parameter | Description | Recommended Value | Remarks |

|---|---|---|---|

| Current Rating | The maximum current the busway can handle | 100A - 5000A | Choose based on load requirements |

| Voltage Rating | Input voltage level for the busway | 120V - 600V | Ensure compatibility with system voltage |

| Construction Material | Material used for the busway housing | Aluminum or Copper | Aluminum is lighter, Copper is more conductive |

| Environmental Rating | Protection against dust and moisture | IP20 to IP66 | Consider installation location |

| Length and Configuration | Overall length and layout of the busway | Customizable | Match with installation space |

| Ease of Maintenance | Maintenance requirements over time | Low to Moderate | Choose designs allowing easy access |

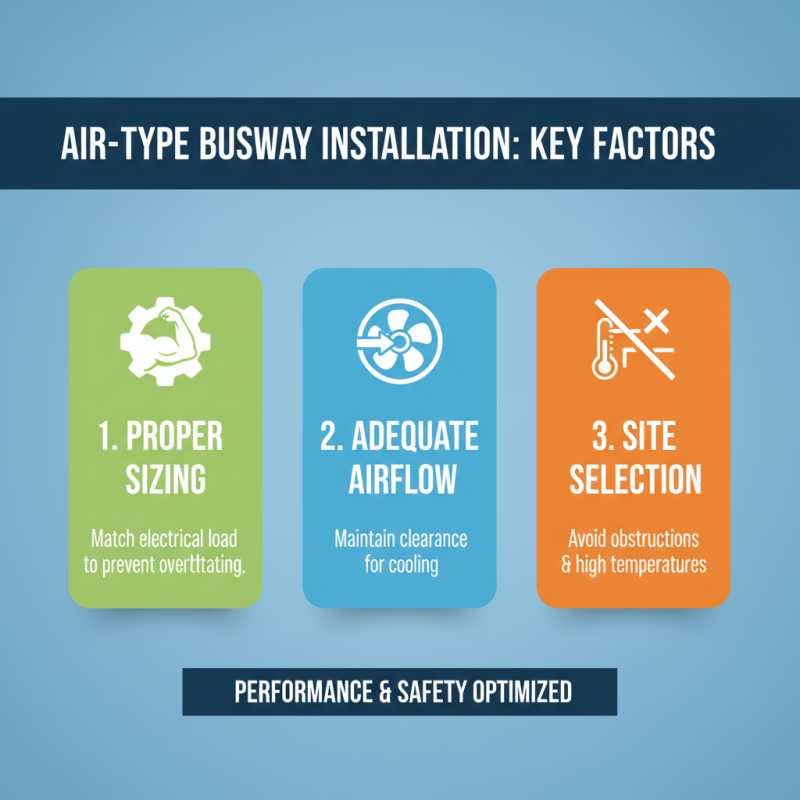

When installing air type busways, it is essential to consider several key factors that can impact both performance and safety. Firstly, proper sizing is crucial; ensuring the busway can handle the expected electrical load without overheating is vital. Adequate airflow must be maintained around the busway to facilitate cooling, which means careful planning of the installation site. Avoiding locations that could become obstructed or subject to high ambient temperatures is also necessary to uphold efficiency.

Maintenance of air type busways is equally important for long-term reliability. Regular inspections should be conducted to check for signs of wear, dirt accumulation, or damage. Cleaning should be performed as needed, as dust and debris can hinder airflow and contribute to overheating. Furthermore, ensuring that all connections remain secure is essential to prevent electrical faults. Establishing a routine maintenance schedule can help identify and resolve potential issues before they lead to system failures, thereby enhancing the lifespan of the busway and ensuring optimal performance.