Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the ever-evolving landscape of electrical systems, the selection of the right components is crucial for ensuring efficiency and reliability. One such component that has gained significant attention in recent years is the Flexible Busbar. According to industry expert John Thompson, a leading specialist in electrical design, "Choosing the right Flexible Busbar is not merely about specifications; it’s about optimizing performance and ensuring safety across your electrical systems." This statement underscores the importance of understanding the various factors involved in the selection process.

Flexible Busbars provide versatility and adaptability, making them ideal for a wide range of applications, from renewable energy systems to commercial electrical installations. However, with numerous options available on the market, professionals face the challenge of identifying the most suitable type for their specific needs. Factors such as electrical load, environmental conditions, and installation space must be carefully considered to make an informed decision.

As we delve deeper into the process of selecting a Flexible Busbar, we will explore the key considerations, advantages, and best practices that can help streamline your choice. Ultimately, the right Flexible Busbar can enhance the efficiency of your electrical systems while ensuring that safety standards are met and exceeded.

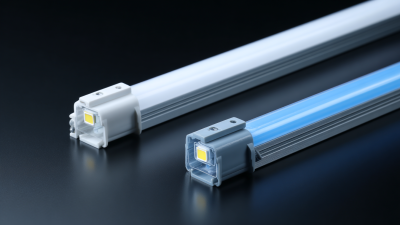

Flexible busbars are crucial components in electrical systems, providing a reliable means of power distribution while accommodating the movement inherent in various applications. These busbars are designed to offer both electrical conductivity and mechanical flexibility, making them ideal for environments where vibration, thermal expansion, and mechanical stress are prevalent. Their unique structure allows for easy installation and maintenance, which is essential in minimizing downtime and maintaining system efficiency.

The applications of flexible busbars are diverse, ranging from automotive and aerospace industries to renewable energy systems and industrial automation. In automotive systems, for instance, they facilitate the complex routing of electrical connections required for modern vehicles, enabling efficient energy management. In renewable energy, flexible busbars support solar panel connections and energy storage systems, adapting to the dynamic layouts often required in these setups. The adaptability of flexible busbars not only enhances the versatility of electrical systems but also contributes to overall safety and reliability, ensuring that power delivery remains smooth and uninterrupted across various operational conditions.

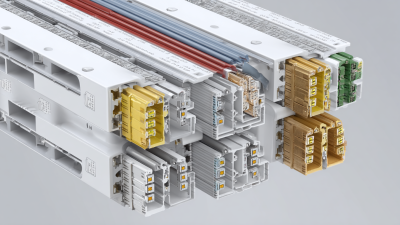

| Busbar Type | Material | Application | Current Rating (Amps) | Flexibility |

|---|---|---|---|---|

| Copper Busbar | Copper | Power Distribution | 600 | Highly Flexible |

| Aluminum Busbar | Aluminum | Renewable Energy Systems | 400 | Moderately Flexible |

| Flat Flexible Busbar | Copper/Aluminum | Industrial Machines | 500 | Very Flexible |

| Modular Busbar | Copper | Data Centers | 800 | Flexible |

| Insulated Busbar | Copper/Aluminum | Substations | 300 | Moderately Flexible |

When selecting the right flexible busbar for electrical systems, several key factors must be considered to ensure optimal performance and reliability. The first essential factor is the current carrying capacity. According to data from the Electric Power Research Institute (EPRI), the busbar’s conductor material, typically copper or aluminum, significantly influences this capacity. Copper busbars offer higher conductivity, meaning they can handle more current with reduced heat generation compared to aluminum. It's critical to assess the specific application requirements to match the busbar’s capacity with the expected electrical load, including any potential future expansion.

Another important factor is the environmental conditions in which the busbar will operate. Flexible busbars are often exposed to various temperatures and humidity levels, which can affect their longevity and performance. A report from the National Electrical Manufacturers Association (NEMA) indicates that busbars used in high-temperature environments may require specialized insulation materials or coatings to prevent degradation. Furthermore, the ease of installation and maintenance should not be overlooked; flexible designs often facilitate quicker assembly and modifications, contributing to overall system efficiency. Therefore, evaluating these factors in conjunction with current and future operational demands will lead to more informed decisions when choosing flexible busbars for electrical systems.

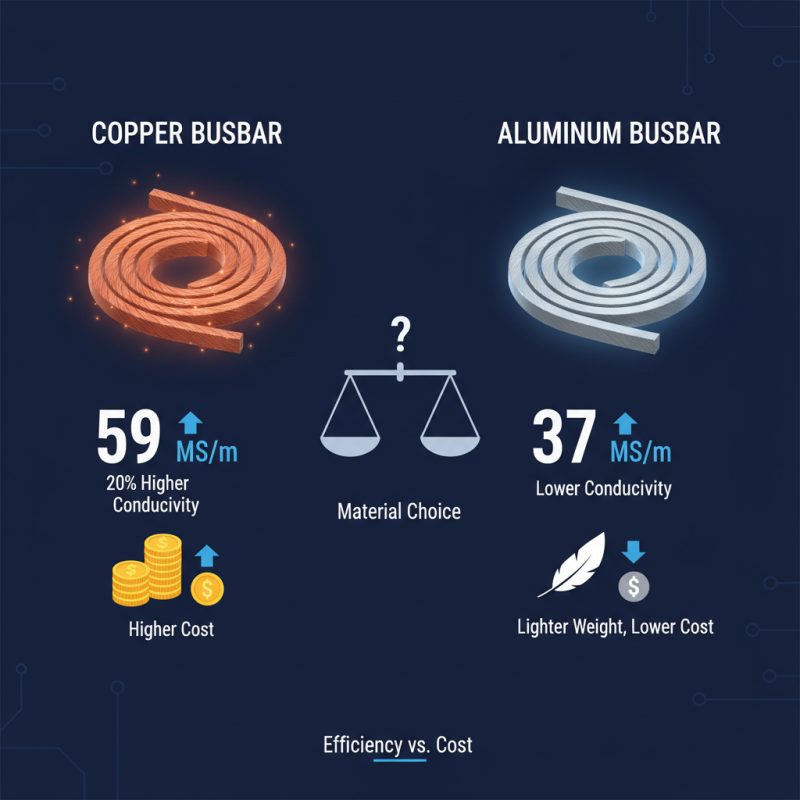

When selecting a flexible busbar for electrical systems, the choice of material plays a crucial role, particularly when comparing copper and aluminum. Copper is well-known for its superior conductivity, with a conductivity rating of approximately 59 MS/m, which is about 20% higher than that of aluminum. This makes copper an ideal choice for applications where efficient energy transfer is essential. However, copper's higher cost can be a significant factor for large-scale projects, prompting many engineers to consider aluminum, which, despite its lower conductivity rating of about 37 MS/m, is considerably lighter and often more cost-effective.

Aluminum's lightweight nature enables easier handling and installation, which can lead to reduced labor costs during installation. Additionally, aluminum busbars exhibit better resistance to corrosion, especially in high-humidity environments, making them suitable for certain applications. According to industry reports, the use of aluminum busbars can lead to a 30% reduction in material costs compared to copper options, influencing many decisions in the commercial and industrial sectors.

Tips: When deciding between copper and aluminum, consider the specific requirements of your system, such as the expected current load, environmental factors, and budget constraints. Additionally, evaluate the potential logistical advantages offered by aluminum in terms of installation processes. Finally, always ensure that the busbar selection aligns with the overall efficiency goals of your electrical system to achieve optimal performance.

When selecting a flexible busbar for electrical systems, design specifications play a vital role in ensuring maximum efficiency and safety. One of the primary considerations is the electrical conductivity of the materials used. High conductivity materials, such as copper or aluminum, minimize resistive losses and enhance the overall performance of the electrical system. Additionally, the busbar's cross-sectional area should be adequately sized to handle the required load currents while ensuring minimal overheating. This involves calculations based on the expected load, ambient temperature, and operating conditions to prevent failures.

Another critical factor is the insulation and protective coatings on the busbar. Proper insulation not only prevents electrical short circuits but also protects against environmental factors such as moisture, dust, and corrosion. The choice of insulation materials must be compatible with the operating voltage and temperature ranges to maintain reliability. Furthermore, flexibility should not compromise rigidity; hence, the design should facilitate ease of installation and adaptability to various configurations within the electrical system. By prioritizing these design specifications, engineers can create flexible busbars that provide both safety and operational efficiency, ultimately leading to more robust electrical systems.

This chart illustrates the current capacity distribution for various types of flexible busbars used in electrical systems. Proper selection of busbars based on current ratings can enhance efficiency and safety in electrical installations.

When it comes to maintaining and installing flexible busbars, several best practices can enhance both safety and efficiency in electrical systems. First and foremost, it’s essential to handle flexible busbars with care during installation. Ensure that the environment is clean and free of contaminants that could lead to corrosion or electrical failures. When connecting the busbars, use proper tools and techniques to avoid physical damage, as improper handling can compromise their performance. Additionally, it's important to follow manufacturer specifications for torque settings and connection methods to maintain optimal conductivity and mechanical integrity.

Regular maintenance of flexible busbars is equally crucial. Schedule routine inspections to check for signs of wear, corrosion, or loose connections. Look for any discoloration or heat-related damage, as these can indicate underlying issues that need addressing. Cleaning the busbars periodically with a non-abrasive cloth can help prevent buildup that may impede functionality. It’s also beneficial to monitor the electrical load and ensure it stays within the rated capacity of the busbars, preventing overheating and prolonging their lifespan. By adhering to these installation and maintenance best practices, you can ensure reliable performance and extend the operational life of your electrical systems.