Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

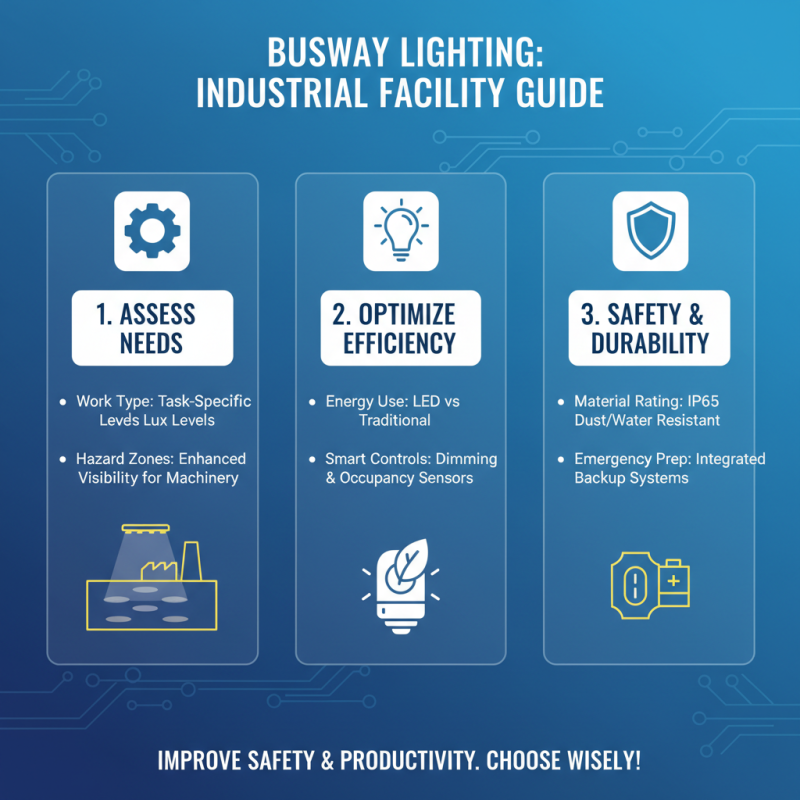

In the pursuit of enhancing operational efficiency and safety in industrial facilities, the selection of appropriate lighting solutions becomes paramount. One critical aspect of this is Busway Lighting, which plays a vital role in illuminating workspaces effectively and promoting productivity. As industrial environments are often complex and varied, choosing the right busway lighting is essential for ensuring that every corner of the facility is adequately lit, thereby reducing the risk of accidents and improving overall visibility.

When considering Busway Lighting, several key factors must be taken into account, including the layout of the facility, the nature of tasks performed, and energy efficiency. The right lighting not only fosters a safer working environment but also contributes to energy savings and reduced operational costs. Moreover, with advancements in technology and design, there are numerous options available that cater to both functional and aesthetic needs. Navigating these options requires a thoughtful approach to ensure that the selected lighting solution aligns with the specific requirements of the industrial space.

Ultimately, making an informed choice about Busway Lighting can have a lasting impact on both safety and productivity levels within industrial facilities. By prioritizing the right lighting solutions, facility managers can create a well-lit, efficient, and safe operational environment conducive to success.

When selecting the best busway lighting for your industrial facility, it's essential to consider several key factors that can significantly impact both safety and productivity. First, evaluate the specific lighting needs based on the nature of your operations. Different areas may require varying levels of illumination, so it's important to assess the work being conducted and the potential hazards present. For instance, areas with heavy machinery may need brighter lighting to ensure visibility, while storage areas might require less intense illumination.

**Tips:** Ensure that the lighting meets the necessary safety standards and is suitable for your facility’s environment. Look for fixtures that are rated for industrial use, as they are designed to withstand harsher conditions, including dust and moisture.

Another important aspect to consider is energy efficiency. High-quality busway lighting options can offer significant energy savings, which not only helps reduce operational costs but also promotes a more sustainable environment. Look for LED options that provide superior durability and longevity compared to traditional lighting systems. Additionally, consider implementing smart lighting controls, which can further optimize energy usage by automatically adjusting brightness based on occupancy.

**Tips:** Perform a thorough audit of your current lighting layout and usage to identify potential areas for improvement. This will help you make informed decisions and select the most appropriate lighting solutions for enhancing both safety and efficiency.

When selecting the best busway lighting for industrial facilities, understanding lumens per watt is crucial for enhancing energy efficiency. Lumens measure the total light output from a fixture, while watts indicate the energy consumed. Therefore, a higher lumens per watt ratio means more light is generated for each unit of energy used, ultimately leading to lower electricity costs. This is especially important in industrial settings where lighting operates for extensive hours each day, significantly impacting overall energy consumption.

To evaluate lighting efficiency effectively, consider the specific tasks and spaces within the facility. Different areas may require varying light intensities and qualities. For instance, workstations that involve intricate tasks benefit from brighter, more focused light, while larger storage areas may only need ambient illumination. By assessing lumens per watt ratings for different fixtures, facility managers can identify options that not only meet the required light levels but also align with sustainability goals. This assessment can lead to long-term savings and improved working conditions, fostering productivity and safety within the industrial environment.

| Lighting Type | Lumens per Watt (Lm/W) | Average Lifespan (Hours) | Energy Efficiency Rating |

|---|---|---|---|

| LED | 80-120 | 25,000 - 50,000 | A+ |

| Fluorescent | 35-100 | 7,000 - 15,000 | B |

| Metal Halide | 65-120 | 15,000 - 20,000 | C |

| High-Pressure Sodium | 80-140 | 24,000 - 36,000 | C |

The color temperature of lighting plays a crucial role in the industrial workplace, influencing both safety and productivity levels. Color temperature, measured in Kelvin (K), determines whether light appears warm or cool. A lower color temperature (around 3000K) emits a warmer, yellowish light that can create a cozy atmosphere but may lead to decreased alertness and focus. Conversely, higher color temperatures (above 5000K) produce a cooler, bluish light that mimics daylight, enhancing visibility and reducing eye strain. This cooler light spectrum is particularly beneficial in environments that require precision and heightened awareness, such as manufacturing assembly lines or quality control areas.

Moreover, the psychological effects of different color temperatures should not be underestimated. Studies indicate that lighting with a higher color temperature can increase productivity by improving concentration and reducing fatigue. In facilities where shift work is common, cooler lighting can help regulate circadian rhythms, combatting the sluggishness associated with night shifts. However, it is essential to balance these benefits with the potential for glare and discomfort. Properly designed lighting systems that incorporate adjustable color temperature settings can provide employees with the necessary illumination while fostering a safe and efficient working environment.

When selecting busway lighting for industrial facilities, durability and reliability are paramount. Harsh environments, often characterized by extreme temperatures, dust, and vibrations, necessitate lighting solutions designed to withstand these challenges. According to the U.S. Department of Energy, industrial lighting accounts for about 25% of total energy consumption in manufacturing facilities. Therefore, choosing high-quality, robust lighting can lead to significant energy savings and reduced maintenance costs.

Research from the Illuminating Engineering Society indicates that LED lighting is particularly effective in industrial settings due to its longevity and resistance to environmental factors. LED fixtures have a lifespan of 50,000 hours or more, compared to traditional lighting options that may only last 10,000 hours. This is crucial for facilities where maintenance can lead to costly downtime. Furthermore, selecting fixtures with appropriate ingress protection (IP) ratings ensures that the lighting can endure exposure to dust, moisture, and corrosive elements, which are common in many industrial environments.

With the rise of smart lighting systems, integrating controls and sensors can further enhance the efficiency and reliability of busway lighting. Studies show that facilities implementing smart lighting strategies can achieve up to 30% energy reduction, while also improving safety and productivity through better illumination. By investing in durable and reliable lighting solutions tailored for harsh industrial environments, facilities can not only improve operational efficiency but also enhance worker safety and satisfaction.

When designing lighting systems for industrial facilities, compliance with established standards is essential to ensure

safety,

efficiency, and effectiveness. The

American National Standards Institute (ANSI) and the Illuminating Engineering Society (IES) play vital roles in setting these standards.

ANSI provides a framework for safety and performance, establishing guidelines that govern the

minimum requirements for lighting installations in diverse environments. These standards help to mitigate risks associated with inadequate lighting,

such as accidents and operational inefficiencies.

American National Standards Institute (ANSI) and the Illuminating Engineering Society (IES) play vital roles in setting these standards.

ANSI provides a framework for safety and performance, establishing guidelines that govern the

minimum requirements for lighting installations in diverse environments. These standards help to mitigate risks associated with inadequate lighting,

such as accidents and operational inefficiencies.

The

IES complements ANSI standards by focusing on performance criteria specifically related to lighting output,

energy efficiency, and visual comfort. Their guidelines help lighting designers

determine optimal illumination levels based on the tasks performed in specific areas within an industrial facility.

By adhering to IES recommendations, facilities can enhance worker productivity and safety while also supporting energy conservation initiatives.

Understanding and applying these compliance standards ensures that your busway lighting not only meets regulatory requirements

but also fosters a well-designed, efficient workspace.

IES complements ANSI standards by focusing on performance criteria specifically related to lighting output,

energy efficiency, and visual comfort. Their guidelines help lighting designers

determine optimal illumination levels based on the tasks performed in specific areas within an industrial facility.

By adhering to IES recommendations, facilities can enhance worker productivity and safety while also supporting energy conservation initiatives.

Understanding and applying these compliance standards ensures that your busway lighting not only meets regulatory requirements

but also fosters a well-designed, efficient workspace.