Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

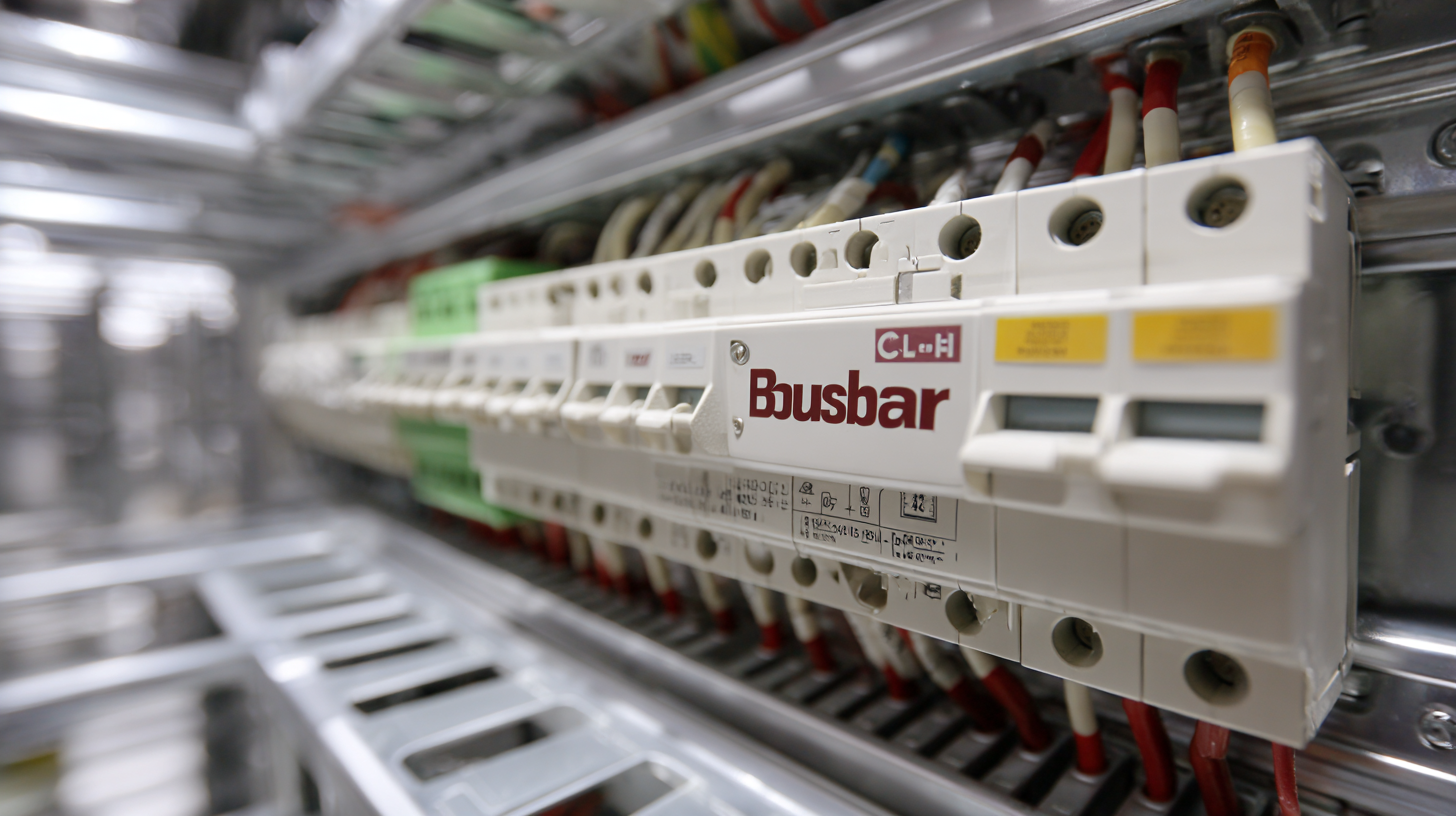

In today’s rapidly evolving electrical infrastructure landscape, the selection of the optimal Busbar Busduct is critical for enhancing efficiency and safety within various projects. According to the latest report by the Global Busbar Market, the demand for Busbars is projected to grow at a CAGR of 5.1% from 2022 to 2027, driven by increased investments in renewable energy and smart grid technologies. The Busbar Busduct system not only facilitates the efficient transfer of electrical power but also offers flexibility in installation and maintenance processes. With a variety of configurations and materials available, making an informed choice can significantly impact the overall performance and operational costs of electrical systems. This checklist aims to outline the top strategies for choosing the best Busbar Busduct for your project, ensuring you connect with industry standards and maximize your system's potential.

When selecting a busbar busduct for your project, understanding the technical specifications is crucial. An effective busduct system should comply with industry standards and ensure reliability and safety in power distribution. Key factors to consider include the current-carrying capacity, which indicates how much electrical load the busduct can handle without overheating. Additionally, the design and materials used in the construction can significantly impact the overall performance and lifespan of the system. With the market for commercial bus duct systems projected to exceed $1 billion in 2023, it is essential to make informed decisions based on these technical parameters.

Another important aspect is the compatibility of the busbar busduct with existing infrastructure. As utility companies around the world undertake significant upgrades to their grids, ensuring that your selected busduct aligns with these changes will be key to future-proofing your energy distribution system. Factors such as ease of installation, maintenance requirements, and the ability to adapt to evolving regulations are critical to sustaining operational efficiency in the long run. By prioritizing these considerations, you can enhance the durability and effectiveness of your power distribution solution.

When choosing the best busbar busduct for your project, adhering to material and manufacturing standards is paramount for ensuring reliability and durability. Recent industry insights highlight that manufacturers are increasingly focused on investing in their digital and data infrastructures to drive innovation and navigate the skills gap. This shift is essential not only for improving production efficiency but also for enhancing product quality. In the realm of bus ducts, sourcing materials that meet stringent standards can significantly impact their performance and longevity.

Tips for selecting the right busduct include examining certifications such as CSA C800-2025, which outlines reliability and quality assurance criteria necessary for energy storage solutions. This standard’s emphasis on safety and performance can be a benchmark for busduct manufacturing, ensuring that your selection will withstand operational stresses over time. Additionally, consider conducting a life cycle assessment during the selection process to evaluate the environmental impact and sustainability of the materials used in your busduct.

Investing in high-quality materials and adhering to recognized manufacturing standards not only safeguards the operational integrity of your electrical systems but also aligns with broader sustainability goals evident in today’s manufacturing landscape. Proper due diligence in choosing the right components lays the groundwork for a robust and durable infrastructure, essential for the demands of modern energy needs.

As the global energy landscape evolves, innovations in busbar technology are becoming increasingly pivotal. China, as a leader in manufacturing and technological development, is at the forefront of these changes. The country’s commitment to enhancing energy efficiency and integrating renewable sources has spurred significant advancements in busbar design and production. These innovations not only improve the operational efficiency of electrical systems, but also contribute to the reduction of energy losses and increased safety standards.

Recent market insights reveal that modular busduct systems are gaining traction due to their flexibility and ease of installation. This trend reflects a growing preference for customizable solutions that can be tailored to specific project requirements. Additionally, advancements in materials, such as lightweight alloys and high-conductivity copper, are enhancing the performance and durability of busbar systems. With a focus on sustainability, manufacturers are also exploring eco-friendly options to meet international standards, making it essential for project planners to stay informed about these developments when selecting busbar solutions for their applications.

When selecting the best busbar busduct for your project, cost analysis is a crucial aspect that cannot be overlooked. Balancing budget constraints against the requirement for high-quality solutions is essential for ensuring the long-term success and efficiency of your electrical systems. With the rapid growth of the smart manufacturing market in the U.S., projected to reach $145.7 billion by 2030, investing in reliable busduct solutions can yield significant returns by optimizing energy distribution and facilitating better operational efficiency.

As organizations increasingly rely on advanced technologies such as AI and cloud data warehousing for operational insights, the importance of high-quality electrical components becomes even more pronounced. The role of busbars in these systems is often overshadowed by more glamorous technology, yet they are fundamental to supporting the infrastructure that powers innovative solutions. A thorough evaluation of the costs associated with various busduct options, while considering their durability and efficiency, will ultimately lead to informed decisions that enhance the value of your project. Investing wisely now can help harness the full potential of your system, ensuring it meets both current and future demands.

| Criteria | Details | Cost Range (per meter) | Quality Rating (1-5) |

|---|---|---|---|

| Material Type | Aluminium | $20 - $30 | 4 |

| Material Type | Copper | $30 - $50 | 5 |

| Current Rating | 800A | $25 - $35 | 4 |

| Current Rating | 1200A | $40 - $60 | 5 |

| Installation Type | Surface Mount | $15 - $25 | 4 |

| Installation Type | Flush Mount | $25 - $45 | 5 |

When it comes to selecting a busbar busduct for your project, understanding safety standards and compliance regulations is crucial. The installation of busbars often involves electrical components that can pose significant hazards if not designed and implemented according to established guidelines. Familiarizing yourself with national and international safety standards, such as the IEC (International Electrotechnical Commission) and NEC (National Electrical Code), will ensure that your project meets all necessary compliance requirements to safeguard both personnel and equipment.

In addition to regulatory standards, it is essential to assess the specific environmental conditions of your installation site. Factors such as temperature fluctuations, humidity levels, and potential exposure to corrosive elements must be considered to select the right type of busbar. Implementation of adequate protective measures, such as insulation and grounding, not only adheres to safety regulations but also enhances system reliability. By prioritizing compliance with safety standards during the selection and installation process, you can significantly mitigate risks and optimize the operational efficiency of your electrical systems.

This chart illustrates the compliance rates of various safety standards relevant to busbar installations. Ensuring adherence to these standards is crucial for project safety and efficiency.