Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

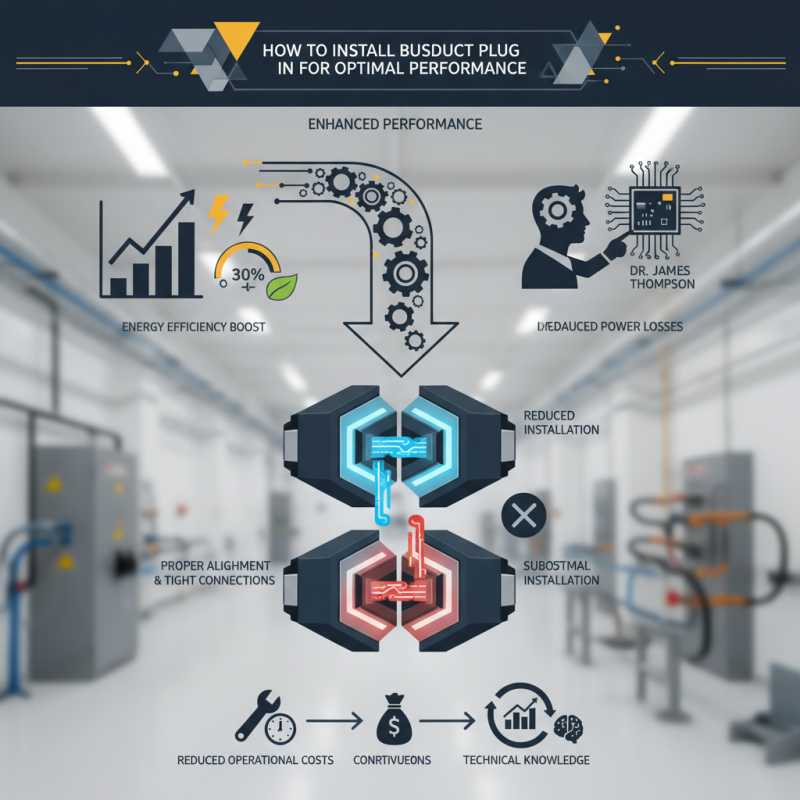

In the world of industrial electrical systems, the integration of Busduct Plug In is crucial for enhanced performance. A recent industry report by the Global Electrical Sector Research Institute highlights that effective Busduct systems can boost energy efficiency by up to 30%. This statistic underscores the importance of proper installation and maintenance of these systems.

Industry expert Dr. James Thompson, a leading authority on electrical distribution, stated, "A well-installed Busduct Plug In can significantly reduce power losses." His insights reflect the growing reliance on advanced technologies to optimize energy management. The repercussions of suboptimal installation can lead to inefficiencies and increased operational costs.

Despite these benefits, many facilities overlook the nuances of Busduct systems. Occasionally, contractors may underappreciate proper alignment and tight connections. Correcting installation errors can be time-consuming and costly. Thus, ensuring optimal performance of Busduct Plug In not only requires technical knowledge but also a commitment to continuous improvement.

The Busduct plug-in is a vital component for efficient electrical distribution. Understanding its key features can help optimize performance. It enables effective connections, allowing for reduced energy losses. This innovation minimizes heat generation and supports higher current capacities. Enhanced safety features are integral, preventing potential hazards.

When installing a Busduct plug-in, consider these tips. Ensure proper alignment of components for an effective fit. Misalignment can lead to inefficiencies. Verify that all connections are secure. Loose connections may cause overheating.

Another feature to note is the flexibility of the Busduct system. It allows for easy adjustments based on changing needs. However, practitioners must regularly monitor connections and inspect for wear. Regular maintenance prevents future complicacies. Failing to address small issues can escalate into bigger problems, impacting overall efficiency.

Preparing for the installation of a busduct plug-in requires a clear understanding of the tools and materials needed. A measuring tape is essential for accurate measurements. You will also need screwdrivers, pliers, and a utility knife. Don't forget a level to ensure everything is aligned properly. Safety gear is crucial as well; wear gloves and safety goggles during installation.

Ensure you have all materials on hand, including connectors and screws. Missing materials can halt progress and lead to frustration. Gather instruction manuals ahead of time. Read them thoroughly before starting. Check each item for defects or missing components. Mistakes can create delays and increase costs.

Once the tools and materials are ready, remember to prepare the workspace. A neat area allows for better focus and efficiency. Maintain a checklist to track progress. Stay organized; it helps prevent errors. Mistakes in installation can affect performance. Review each step carefully before proceeding.

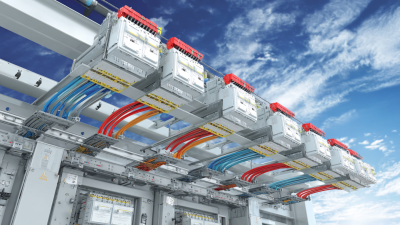

Installing busduct plug-ins can significantly enhance electrical efficiency. This process requires careful planning and execution. Begin by gathering the essential tools. You’ll need basic electrical tools and safety equipment. Wear gloves and goggles throughout. Preparing your workspace is crucial. Ensure there’s good ventilation and no obstructions in the way.

Next, turn off all power sources. This step is vital to avoid accidents. Mark the installation area. Align the busduct with the designated points on the wall or ceiling. Securely fix the plug-in to the busduct. Take your time here; a rushed job can lead to issues later. After connecting, double-check all connections. A small oversight can affect overall performance.

Finally, restore power cautiously. Monitor the system for any unusual sounds or smells. It's easy to miss minor issues at first. If something seems off, revisit your connections. Reflect on the experience. Installation can be a learning curve, and every mistake is an opportunity to improve future projects.

During the installation of busduct plugs, several common issues can arise. Improper alignment is one of the frequent problems. It’s crucial to ensure all components fit snugly together. Gaps may lead to inefficiency or even system failure. Another issue is the inadequate tightening of connection screws. Loose screws may cause overheating and increase the risk of electrical fires. Regularly inspect these connections.

Users often overlook the importance of environmental factors. Dust and debris can interfere with the junctions. Cleaning the installation area before beginning can save time and prevent mishaps. If you notice any unusual sounds during the operation, it may indicate a misaligned component. Your instincts are vital here. Listen closely and check everything.

One common mistake is not consulting the installation manual thoroughly. Skipping steps can lead to significant problems. Take your time to understand the process completely. Lastly, be prepared for unexpected challenges. Sometimes, the components may not behave as expected. Document these occurrences for future reference. Each installation offers lessons that can enhance future performance.

Busducts are essential for energy distribution in modern facilities. They offer efficient solutions, but maintaining their performance is critical. Regular checks help to identify issues early. An IEEE report states that routine inspections can reduce failures by up to 30%. This highlights the importance of proactive maintenance.

Cleaning is a key aspect of busduct upkeep. Dust and debris can cause overheating. Reports indicate that 40% of electrical failures are linked to environmental factors. Ensuring that busducts are free from contaminants can extend their lifespan. Additionally, upgrading components, like connectors, can enhance performance. Industry standards suggest that updating aging infrastructure can yield energy savings of 15-20%.

However, many facilities neglect this aspect. Ignoring minor signs of wear may lead to larger problems. It’s easy to overlook small maintenance tasks. Yet, these tasks can save significant costs in the long run. Reflection on past failures can guide better practices in the future. Investing time now may prevent costly repairs later.