Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

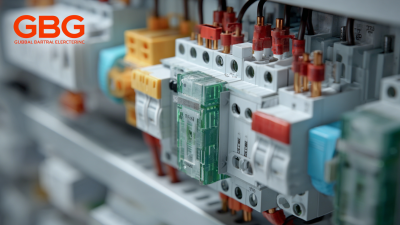

In the realm of electrical engineering and power distribution, Busbar Systems play an integral role in ensuring efficient and reliable transmission of electricity across various applications. As a crucial component of electrical infrastructure, busbars enable the conduction of high currents in a compact and organized manner, facilitating the connection between power sources, transformers, and distribution units. In this article, we delve into the top 10 busbar systems that are essential for optimizing power distribution in modern facilities.

With the increasing demands for energy efficiency and sustainability, understanding the diverse types of busbar systems available can empower engineers and facility managers to make informed decisions for their projects. From traditional copper busbars to innovative aluminum options, each system has its unique advantages that cater to specific operational requirements. Additionally, advancements in technology have led to the emergence of specialized busbar designs that enhance safety, reduce installation time, and improve overall performance.

Join us as we explore these top busbar systems, highlighting their features and applications to guide you towards the best solutions for efficient power distribution.

When selecting modern busbar systems for efficient power distribution, it's crucial to consider several essential features. One of the primary aspects is the thermal conductivity of the materials used. High conductivity materials, such as copper or aluminum, are vital as they minimize energy loss during transmission and enhance overall system performance.

Additionally, the busbar's insulation quality plays a significant role; robust insulation materials can prevent power leakage and protect the system from short circuits, thus ensuring safety and reliability.

Another important feature to evaluate is the busbar's mechanical strength and flexibility. A well-designed busbar system should withstand thermal expansion and mechanical stresses without compromising its integrity.

Furthermore, modular design options provide ease of installation and maintenance, allowing for seamless upgrades or modifications in response to changing power demands. Lastly, consider advanced monitoring capabilities that some systems offer, which help track performance metrics and facilitate proactive maintenance, ultimately enhancing operational efficiency and longevity of the power distribution system.

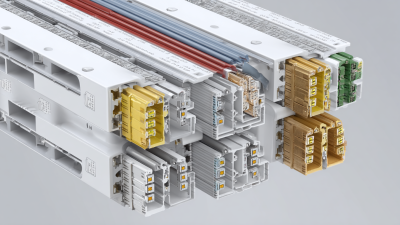

When it comes to power distribution, one of the critical decisions is selecting the appropriate type of busbar system. Insulated busbars and exposed busbars each have distinct advantages and disadvantages that can impact overall efficiency and safety. Insulated busbars are encased in protective layers, which reduce the risk of electrical faults and accidental contact. This added layer of safety makes them ideal for applications in environments where exposure to moisture or human interaction is a concern. Furthermore, insulated busbars typically require less space and can be installed in tighter configurations, making them suitable for modern, compact electrical designs.

On the other hand, exposed busbars offer their own benefits, particularly in terms of heat dissipation and maintenance. With open designs, they allow for better air circulation, which can be advantageous in high-load applications to avoid overheating. Additionally, exposed busbars are often easier to inspect and repair, enabling quicker maintenance and lower operational downtime. However, they come with a higher risk of electrical hazards, making strict safety protocols essential. Ultimately, the choice between insulated and exposed busbars will depend on the specific requirements of the installation, including safety considerations, space constraints, and maintenance needs.

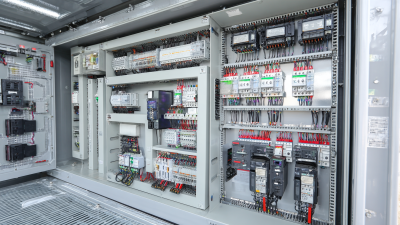

Implementing busbar systems in power distribution offers several key benefits that enhance efficiency and reliability. Firstly, busbars provide a compact and organized way to conduct electricity, allowing for higher current capacity compared to traditional cabling systems. This reduction in space not only leads to lower installation costs but also enables better utilization of available space in substations and industrial facilities. Furthermore, the streamlined design minimizes electrical losses, ensuring that more power reaches its destination without waste.

Another significant advantage of busbar systems is their adaptability and scalability. As energy demands evolve, busbars can be easily reconfigured or expanded to accommodate additional circuits or loads. This flexibility is crucial for modern electrical systems that require ongoing modifications to meet changing operational needs. Additionally, busbar systems are typically easier to maintain than extensive wiring networks, leading to reduced downtime and lower operational risks. The robustness of these systems also contributes to enhanced safety, minimizing the likelihood of electrical fires or failures.

| Busbar System | Material | Current Rating (A) | Temperature Rating (°C) | Application Area |

|---|---|---|---|---|

| Aluminum Busbars | Aluminum | 1000 | 80 | Industrial Facilities |

| Copper Busbars | Copper | 1200 | 90 | Commercial Buildings |

| Insulated Busbars | Insulated Copper | 800 | 70 | Data Centers |

| Flexible Busbars | Copper | 600 | 75 | Renewable Energy |

| Busway Systems | Aluminum | 2000 | 100 | Large Scale Plants |

| Modular Busbars | Copper/Aluminum | 1500 | 85 | Factory Automation |

| Vertical Busbars | Copper | 1800 | 95 | Commercial Installation |

| High Voltage Busbars | Copper | 3000 | 150 | Power Generation |

| Low Voltage Busbars | Aluminum | 400 | 60 | Building Electrical Systems |

Innovative busbar technologies are reshaping the landscape of energy management, providing smarter and more efficient solutions for power distribution. These advancements not only enhance the performance of electrical systems but also contribute to energy savings and operational reliability. Modern busbar systems utilize lightweight materials and modular designs, which facilitate easier installation and maintenance while minimizing energy losses. As industries move toward sustainability, integrating these advanced busbar technologies becomes essential for optimizing energy usage and reducing carbon footprints.

Tip: When evaluating busbar systems, consider their thermal management capabilities. Effective heat dissipation can prolong the lifespan of the equipment and enhance overall system efficiency.

Furthermore, the adoption of smart technologies in busbar systems allows for real-time monitoring and diagnostics. This capability enables facility managers to quickly identify potential issues, ensuring minimal downtime and maximizing productivity. Innovations such as IoT integration and advanced sensor technology are pivotal in driving this shift, as they provide vital insights into power distribution patterns.

Tip: Ensure that your busbar system is compatible with smart monitoring technology to leverage full operational benefits and enhance energy management strategies.

Maintaining busbar systems is crucial for ensuring their longevity and efficiency in power distribution. Regular inspections are essential; according to the International Electrotechnical Commission (IEC), over 30% of power distribution failures can be traced back to inadequate maintenance practices. Implementing a scheduled maintenance routine that includes visual inspections, cleaning, and thermal imaging can help identify potential issues before they escalate. This proactive approach not only reduces the likelihood of equipment failures but also enhances the overall reliability of the power distribution network.

In addition to routine inspections, it's vital to monitor the thermal performance of busbar systems. A report by the IEEE indicates that thermal degradation can cause a reduction in performance efficiency by up to 20% if left unaddressed. Utilizing thermal cameras to detect hotspots and conducting regular continuity tests can help ensure that the busbars are operating within their optimal temperature range. Furthermore, maintaining proper connections and ensuring that the busbars are clean and free from corrosion will significantly contribute to their operational efficiency and lifespan. By adhering to these maintenance tips, organizations can effectively minimize downtime and enhance the reliability of their power distribution systems.