Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

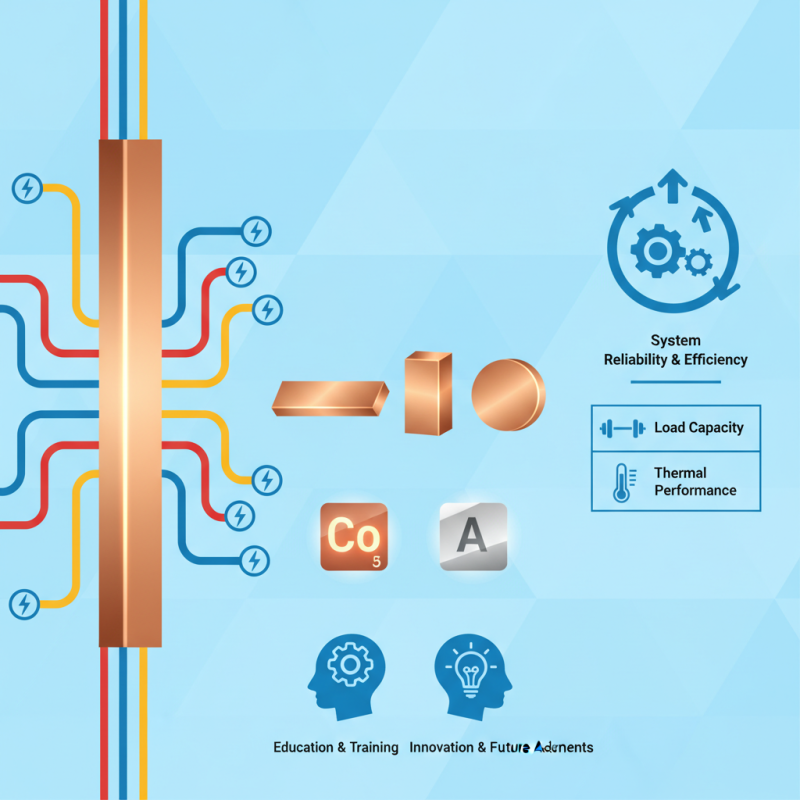

In the world of electrical engineering, the term "Bus Bar" often comes up. A Bus Bar is a critical component that distributes electrical power effectively. It serves as a conductive material that connects multiple circuits. According to Dr. James Carter, an expert in electrical systems, "A well-designed Bus Bar can enhance system reliability and efficiency." This idea emphasizes the importance of Bus Bars in modern electrical applications.

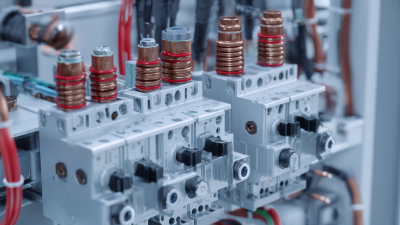

Bus Bars come in various shapes and sizes to suit different needs. They can be made of copper or aluminum, depending on specific requirements. However, misconceptions about Bus Bars exist. Some people assume they are all the same, which is far from true. The design and insulation affect their effectiveness.

Understanding how Bus Bars work is vital for engineers and technicians. They must consider load capacity and thermal performance. Failing to do so could lead to inefficiencies or accidents. This highlights the necessity of proper education and training in the field. A reflective approach to learning and innovation about Bus Bars is essential for future advancements.

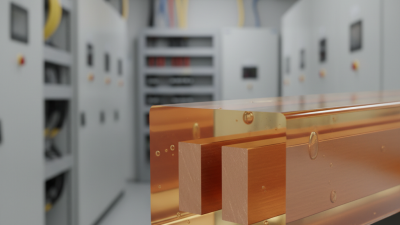

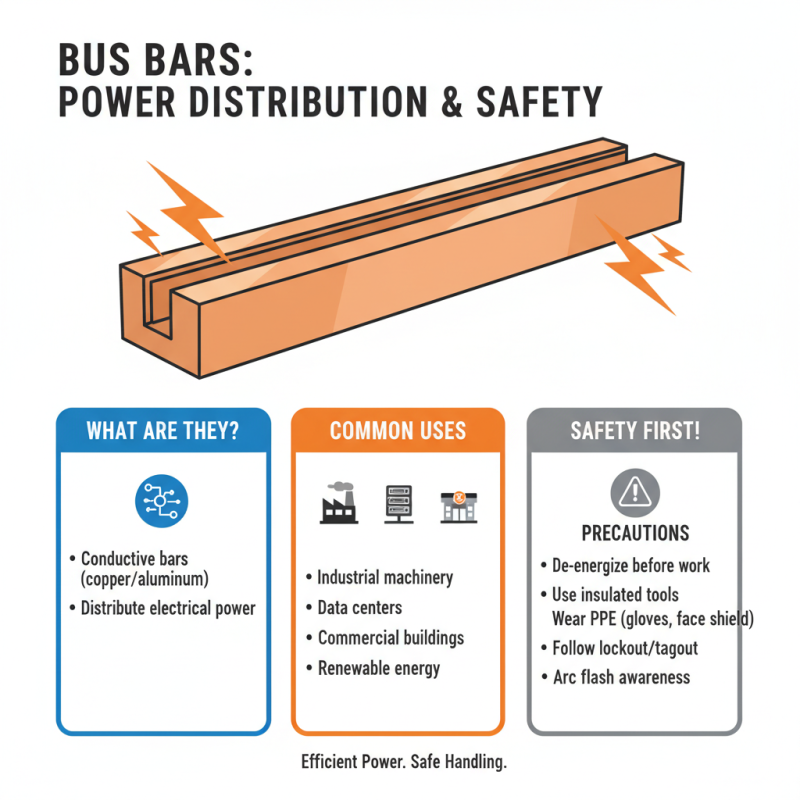

A bus bar is a metal strip or rod that conducts electricity. It is essential in electrical systems. Bus bars connect multiple circuits and distribute power efficiently. They come in various shapes, typically rectangular or cylindrical. Common materials include copper and aluminum, known for their excellent conductivity.

Key characteristics of a bus bar include its current-carrying capacity. According to industry reports, copper bus bars can carry up to 1,000 amperes per square inch. This capacity makes them suitable for high-load applications. Thermal management is another crucial aspect. Improper heat dissipation can lead to failures.

Many engineers overlook the importance of regular inspections. Wear and tear can compromise performance. A study showed 30% of electrical failures were due to inadequate maintenance of bus systems. Investing in robust design and routine checks can enhance reliability. A well-maintained bus bar system ensures safety and efficiency.

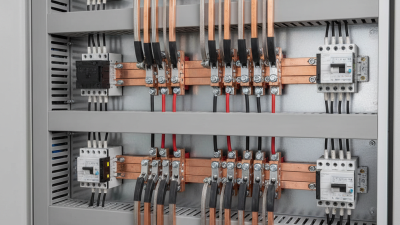

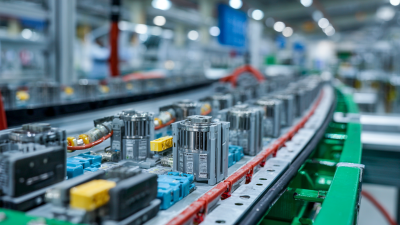

Bus bars are critical components in electrical systems. They act as conductors that distribute power across various circuits. Different types of bus bars are used for differing applications. Each type serves a unique purpose based on design and material.

Metallic bus bars are the most common.

They are usually made from copper or aluminum. Copper provides excellent conductivity. Aluminum is lighter and often less expensive. In some systems, insulated bus bars are used. These prevent accidental contact and enhance safety. They are especially important in high voltage applications.

Tip:

Always check the specifications for your system. Not every bus bar suits every application.

Another type is compact bus bars. These are designed to save space while handling high current loads. They are often used in tight industrial settings. Busducts are long and have multiple tap-off points. This flexibility is beneficial in large facilities.

Tip:

Make sure to consider the size. Overcrowded spaces can lead to overheating risks.

Choosing the right bus bar improves system efficiency. It can prevent costly maintenance down the line. It's essential to match the bus bar type to your electrical needs.

Bus bars play a crucial role in electrical distribution systems. These conductive bars help in efficiently distributing electricity across various components. They are typically made from materials like copper or aluminum. This reduces resistive losses and improves overall efficiency. Reports show that effective bus bar designs can enhance system reliability by up to 25%.

In commercial buildings, bus bars allow for flexible and modular layouts. They provide an easy way to connect transformers, switchgear, and other essential equipment. Their compact design often saves space. However, improper installation can lead to performance issues. Regular maintenance is essential to avoid overheating and corrosion. Some studies suggest that nearly 30% of bus bar failures occur due to inadequate upkeep.

Bus bars also contribute to safety in electrical systems. They minimize the risk of electrical fires when correctly applied. Despite this, the industry still sees lapses. Poor choice of materials or design errors can lead to catastrophic failures. Continuous education is vital for engineers and technicians in this constantly evolving field. Better understanding can lead to safer, more efficient electrical distribution.

Bus bars play a crucial role in electrical distribution systems. Installing them requires careful planning. The layout must accommodate future expansion and maintenance needs. It's essential to ensure proper clearance and accessibility. These factors can be easily overlooked.

During installation, securing connections is vital. Loose connections may lead to overheating or failure. Regular inspections should be part of the maintenance routine. Check for signs of corrosion or wear. Address these issues promptly to avoid larger problems down the line.

Workers must also be trained on safety measures. Electricity poses significant risks. An untrained worker may inadvertently create hazards. Establishing a solid maintenance schedule can help prevent accidents. Frequent checks and balances are crucial for longevity and safety. The bus bar's functionality relies on attention to detail and proactive measures.

Bus bars are essential components in electrical systems. They distribute power efficiently in various applications, from industrial to commercial settings. However, working with bus bars involves specific safety considerations.

Safety should always be a priority. Make sure to wear appropriate personal protective equipment (PPE). This includes gloves, goggles, and fire-resistant clothing. Inspect bus bars for any wear or damage before use. These checks can prevent unexpected accidents.

Here are some tips: Always de-energize the bus bar before any work. Keep the area around bus bars clear. Avoid overcrowding with tools and materials. This can minimize risks of accidents. Understanding proper installation procedures is equally crucial. Improper connections can lead to overheating or electrical failures.

A common oversight is neglecting the expansion and contraction of materials. Temperature changes can cause stress. This could damage the connections over time. Regular maintenance checks can help identify these issues. Taking small, proactive steps can ensure safety and reliability when using bus bars.