Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

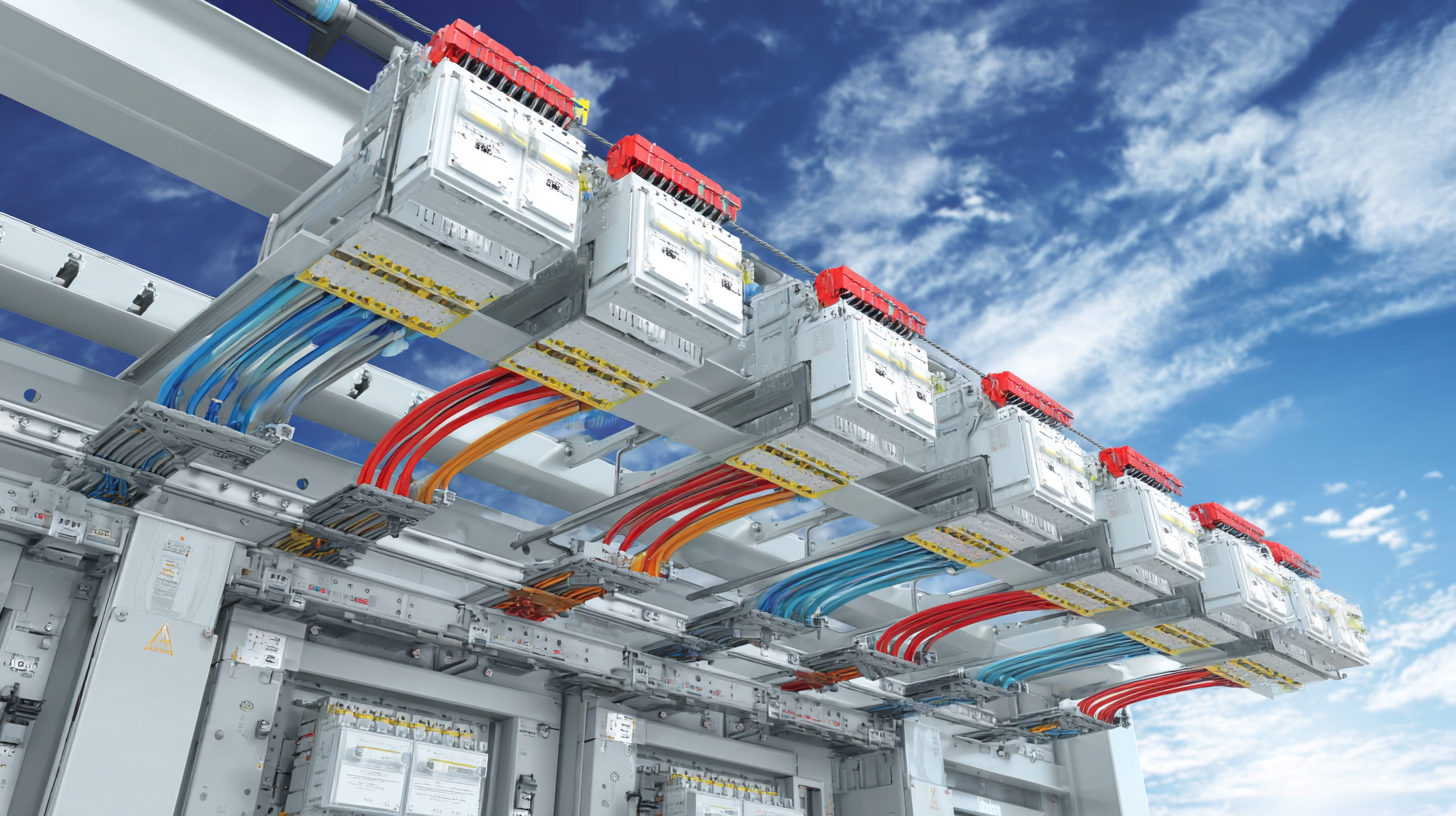

In the ever-evolving landscape of industrial infrastructure, the choice of electrical distribution systems plays a critical role in ensuring operational efficiency and safety. Among various options, the Bus Duct Trunking System has emerged as a preferred solution, increasingly adopted in significant global projects. According to a report by Research and Markets, the global bus duct market is projected to reach USD 7.4 billion by 2024, growing at a CAGR of 5.3% from 2019. This growth is driven by the need for reliable and flexible power distribution in sectors such as manufacturing, data centers, and commercial facilities. The Bus Duct Trunking System not only offers superior performance in power delivery but also ensures space optimization and ease of installation. With a robust design and the ability to accommodate expanding power demands, it stands out as a crucial component in modern electrical infrastructure. Here, we explore the five best reasons why opting for a Bus Duct Trunking System can significantly enhance the efficiency and reliability of your global projects.

When considering bus duct trunking systems for global projects, understanding the key industry standards is crucial for ensuring safety, reliability, and compliance. Standards such as IEC 61439 and UL 857 outline essential criteria for performance and durability, ensuring that systems can handle the electrical demands of modern infrastructures. According to a recent industry report by Frost & Sullivan, the global bus duct market is predicted to grow at a compound annual growth rate (CAGR) of 5.2% through 2026, driven by rising demand for efficient power distribution solutions.

**Tip:** Ensure your bus duct system complies with local regulations and international standards. This will not only facilitate smoother installation processes but also enhance the overall safety of your electrical distribution systems.

Additionally, integrating bus duct trunking systems can significantly reduce installation time and labor costs, as indicated by a study published by the IEEE. It emphasizes that using a modular approach allows for swift assembly and adaptability in design, which is particularly beneficial in projects across diverse geographical locations. Systems designed to fit flexible layouts can minimize disruptions and maximize efficiency in energy distribution.

**Tip:** Choose a manufacturer that offers comprehensive support, including design assistance and compliance verification, to streamline your project timeline and elevate the quality of the final installation.

| Reason | Description | Advantages |

|---|---|---|

| Space Efficiency | Bus duct trunking systems occupy less space than traditional wiring methods, enabling efficient use of available area. | Maximized floor space, easier layout design. |

| Safety Standards | Comply with international electrical safety standards, reducing hazards associated with electrical installations. | Enhanced worker safety, reduced risks. |

| Installation Speed | Quick and straightforward installation process compared to conventional cabling. | Lower labor costs, reduced project timelines. |

| Flexibility | Easily expand or modify the system to accommodate changing electrical demands in a facility. | Adaptable to future needs, cost-effective adjustments. |

| Energy Efficiency | Designed to minimize energy loss during power distribution, contributing to lower operational costs. | Reduced energy costs, environmentally friendly. |

In the realm of electrical infrastructure, bus duct trunking systems offer numerous advantages that make them ideal for global projects. A report by MarketsandMarkets estimates that the global bus duct market will reach USD 4.3 billion by 2026, driven by the rising demand for efficient power distribution solutions. One key benefit of bus duct systems is their space-saving design, which allows for more efficient use of building layouts in industrial and commercial settings. This modular approach reduces the need for extensive cabling, making installations less cumbersome and more adaptable to changing project requirements.

Moreover, bus duct systems enhance safety and maintenance efficiency. A study from the Institute of Electrical and Electronics Engineers (IEEE) indicates that proper installation and maintenance of electrical systems can reduce downtime by up to 30%. Bus duct systems provide greater accessibility for routine inspections and repairs compared to traditional wiring methods. This translates into lower operational costs and improved reliability, essential considerations for any global project where operational efficiency is paramount. Ultimately, the blend of cost-effectiveness, safety, and adaptability makes bus duct trunking systems a compelling choice for electrical projects worldwide.

When selecting the right bus duct trunking system for your global projects, it is essential to consider several key factors that ensure optimal performance and safety. First, assess the load capacity requirements specific to your application. Industry reports, such as those from Research and Markets, indicate that the global bus duct market is projected to grow at a CAGR of 5.2% through 2025, underscoring the increasing demand for robust systems capable of handling significant electrical loads. Ensure that the selected system aligns with these demands to prevent failure or inefficiency in high-capacity environments.

Another critical aspect is the environmental conditions where the bus duct will be installed. According to the International Electrotechnical Commission (IEC), differential factors such as temperature, humidity, and exposure to corrosive agents can significantly impact the longevity and reliability of trunking systems. Selecting a bus duct with adequate protective features and materials designed for specific environmental challenges can enhance durability and performance. Furthermore, always evaluate manufacturer certifications and compliance with international standards, as this not only guarantees quality but also fosters a smoother integration into your project.

This chart illustrates the key advantages of using bus duct trunking systems in global projects, providing a clear comparison of factors that influence project decisions.

When comparing different types of bus duct trunking systems, it's essential to consider factors such as

design flexibility,

environmental conditions, and

installation ease. A well-designed bus duct system stands out by its adaptability to varying project requirements.

Some systems allow for customized layouts, enabling easy integration within existing structures. Consider selecting systems that offer modular components, as these can save both time and costs during installation and future expansions.

Some systems allow for customized layouts, enabling easy integration within existing structures. Consider selecting systems that offer modular components, as these can save both time and costs during installation and future expansions.

Another critical aspect to evaluate is the material used in the bus duct trunking. Aluminum and steel are common options, each with distinct benefits. Aluminum is lighter and offers excellent corrosion resistance, making it suitable for diverse environments. On the other hand, steel provides robustness and durability, ideal for heavy-duty applications. Assess the specific demands of your project to choose the best material.

Tips: Always review the thermal management properties of bus ducts, as effective heat dissipation can enhance system longevity. Additionally, prioritize systems with easy maintenance features; this can significantly reduce downtime during servicing. Keeping these considerations in mind will help you select a bus duct trunking solution that meets your project's unique needs.

Navigating industry regulations is critical for successfully implementing bus duct trunking systems in global projects. The bus duct market is projected to grow significantly, from USD 12.91 billion in 2024 to USD 16.60 billion by 2029, with a CAGR of 5.2%. This growth is propelled not only by advancements in technology but also by stringent regulatory frameworks that ensure safety and efficiency. Keeping abreast of regulations like the Truck and Bus Regulation, which has been effective since December 2008, is essential for project compliance. As of January 1, 2023, all diesel-powered vehicles in California must adhere to these regulations, reflecting a broader trend towards environmental sustainability.

When choosing bus duct systems, it's important to factor in compliance with local and international regulations. Often, EPC contractors can benefit from partnering with suppliers who have extensive knowledge of these regulatory landscapes, ensuring that projects meet safety standards without delays.

Tips: Consider consulting industry reports to stay updated on regulation changes, and do thorough research on suppliers who can provide expertise in navigating these complexities. Additionally, invest time in training your project teams about these regulations to enhance awareness and compliance throughout the project lifecycle.