Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

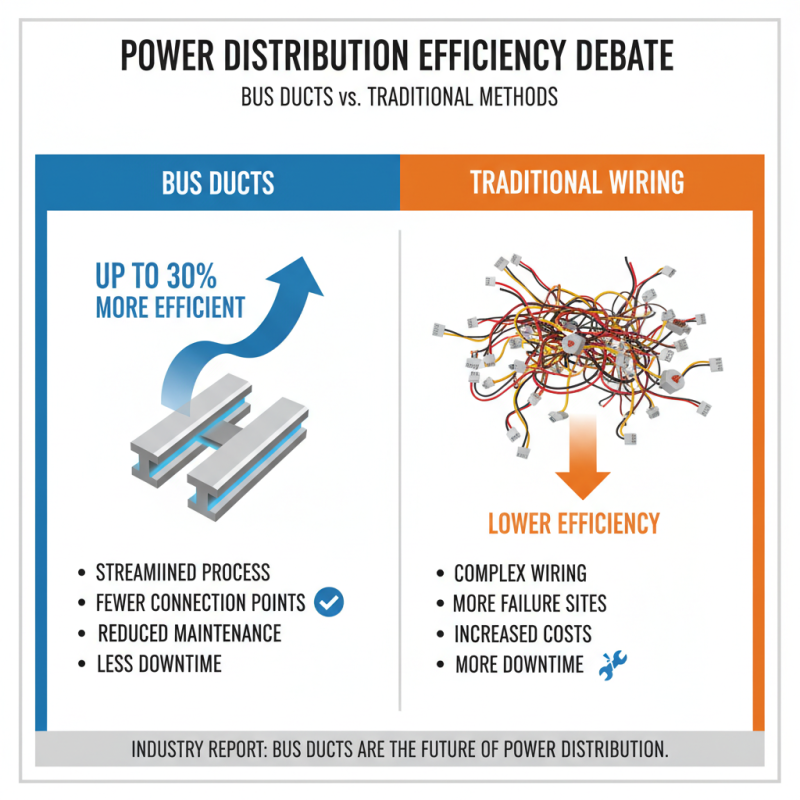

In the ever-evolving landscape of electrical systems, efficient power distribution is essential. Bus duct in electrical applications has become crucial for optimizing performance. According to a recent report by the International Electrotechnical Commission, bus duct systems can improve energy efficiency by up to 30% compared to traditional cable systems.

Renowned industry expert Dr. Emily Thompson emphasizes the importance of this technology. She states, "Investing in modern bus duct in electrical systems is not just a trend; it’s a necessity for future-ready infrastructure." The demand for electricity continues to climb, creating a need for innovative solutions in power distribution.

While bus duct systems have significant advantages, they are not without challenges. Installation and maintenance can present hurdles that require skilled professionals. Moreover, the initial investment may deter some organizations. Reflecting on these obstacles is important for decision-makers looking to enhance their systems. Balancing innovation with practical implementation remains a key consideration in adopting bus duct solutions for energy efficiency.

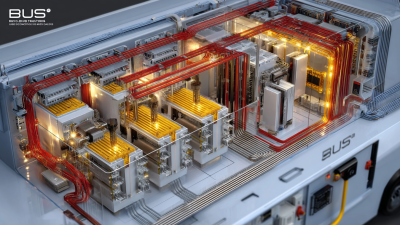

Bus ducts play a crucial role in electrical systems. They serve as conduits for distributing electrical power efficiently. Unlike traditional wiring, bus ducts are compact and versatile. They can be installed in various configurations, saving space and facilitating maintenance.

These systems consist of copper or aluminum bars, enclosed in protective casings. This design helps in reducing electrical losses, ensuring a more reliable power flow. However, installation can be complex. Proper planning is essential to avoid future issues like overheating or short circuits. Regular inspections and maintenance are also necessary to keep the system in optimal condition.

While bus ducts enhance efficiency, they require careful handling. Improper installation can lead to serious safety hazards. Moreover, identifying the right size and type for a specific application can be challenging. A miscalculation may result in insufficient power supply or costly upgrades. Overall, understanding the function of bus ducts is vital for anyone involved in electrical systems.

Bus ducts offer significant advantages for power distribution systems. They are efficient and facilitate a more organized layout in electrical installations. Their compact design allows for a higher power density, reducing the space needed for electrical wiring. According to industry reports, bus duct systems can improve energy efficiency by up to 30%. This is crucial for modern facilities aiming to minimize operational costs.

One striking feature of bus ducts is their durability. They require less maintenance compared to traditional wiring methods. The enclosed design protects against environmental factors and physical damage. This can lead to reduced downtime and lower repair costs. However, installing a bus duct requires careful planning. Miscalculations can lead to inefficiencies during operation or even safety issues.

Tips: Always analyze the layout before installation. Evaluate the specific power needs of your facility. Consider future growth to avoid costly retrofits. Regular inspections can catch potential issues early. Balancing efficiency and practicality is key.

Bus ducts are essential for efficient power distribution in electrical systems. They allow electricity to flow with minimal resistance and help reduce energy losses. Various materials are used to construct bus ducts, such as copper and aluminum. Copper is highly conductive but can be expensive. Aluminum, on the other hand, is lighter and cost-effective but may not perform as well under high current loads.

Different configurations of bus ducts serve varying needs. For example, compact bus ducts save space, making them ideal for areas with limited installation room. However, these designs might not accommodate future expansion easily. Meanwhile, open bus ducts allow for easier maintenance but expose conductors to environmental factors, like dust and moisture. Each type has its pros and cons, requiring careful consideration during design.

Installation challenges can arise, especially in complex systems. Improper alignment can lead to overheating. Regular inspection is important to ensure connections remain secure. The range of materials and configurations makes it crucial to evaluate specific project requirements. Tailoring your choice can optimize performance and reliability in power distribution systems.

This chart presents the efficiency ratings of various types of bus ducts used in electrical systems, ranging from metal enclosed bus ducts to insulated and copper variants. A higher rating indicates better efficiency in power distribution.

The installation of bus ducts is crucial for efficient power distribution in electrical systems. Proper installation ensures minimal energy loss and increased system reliability. Experts recommend following strict guidelines during installation. For instance, bus ducts should be mounted securely to avoid movement. Conductors must be aligned to prevent overheating. According to a report by the Electric Power Research Institute, poorly installed bus ducts can lead to 10-15% energy loss.

Maintenance is equally important. Regular inspections can identify potential issues before they escalate. Electrical systems should be checked for signs of wear and tear. Connections should be tightened to ensure integrity. Data from the Institute of Electrical and Electronics Engineers indicates that organizations that prioritize maintenance reduce failure rates by over 20%. Small issues can snowball into significant failures, resulting in costly repairs and downtime.

Bus ducts must be cleaned periodically to avoid dust accumulation. Dust can lead to insulation failure and increase fire risks. However, many facilities neglect this crucial task due to time constraints. Reflecting on maintenance practices highlights areas for improvement. A proactive approach can enhance efficiency and longevity in electrical systems. Continuous evaluation of both installation and maintenance ensures optimal performance and safety standards.

| Bus Duct Type | Material | Current Rating (A) | Length (m) | Maintenance Frequency (Years) |

|---|---|---|---|---|

| Indoor Bus Duct | Aluminum | 800 | 3 | 5 |

| Outdoor Bus Duct | Copper | 1200 | 5 | 3 |

| Modular Bus Duct | Steel | 1000 | 4 | 4 |

| Channel Bus Duct | Aluminum | 600 | 2 | 6 |

| Insulated Bus Duct | Copper | 1500 | 6 | 5 |

In the debate between bus ducts and traditional power distribution methods, bus ducts stand out for efficiency. A recent industry report suggests that they can improve power distribution efficiency by up to 30%. Traditional methods often rely on complex wiring, which can lead to increased maintenance costs and downtime. Bus ducts streamline this process. They reduce the number of connection points and potential failure sites.

Safety is another factor to consider. Bus ducts are designed with enhanced insulation. This feature minimizes the risk of electrical shock, which is a concern in traditional systems. A survey found that 15% of electrical failures could be traced back to poor insulation in conventional setups. It’s critical to evaluate these issues when choosing a system.

However, the upfront cost of bus ducts can be higher. Some project managers hesitate when implementing them. They may need more training for installation and maintenance. The long-term savings in efficiency may outweigh these initial costs. But it requires a thoughtful approach to budget and resource allocation.