Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In today's fast-paced industrial landscape, the need for efficient power distribution systems has never been more critical. Among the various options available, the Air Type Busway stands out as a reliable solution for managing electrical power in commercial and industrial applications. With its unique design that leverages air as an insulating medium, this type of busway not only enhances safety and efficiency but also reduces maintenance costs. However, navigating the specifications and selecting the right Air Type Busway for your specific needs can be daunting.

In this blog, we will explore the essential specifications of Air Type Busway systems and provide you with top strategies to choose the best option that aligns with your operational requirements and goals. Whether you're upgrading your existing infrastructure or planning a new installation, understanding these key aspects will empower you to make informed decisions and optimize your power distribution strategy.

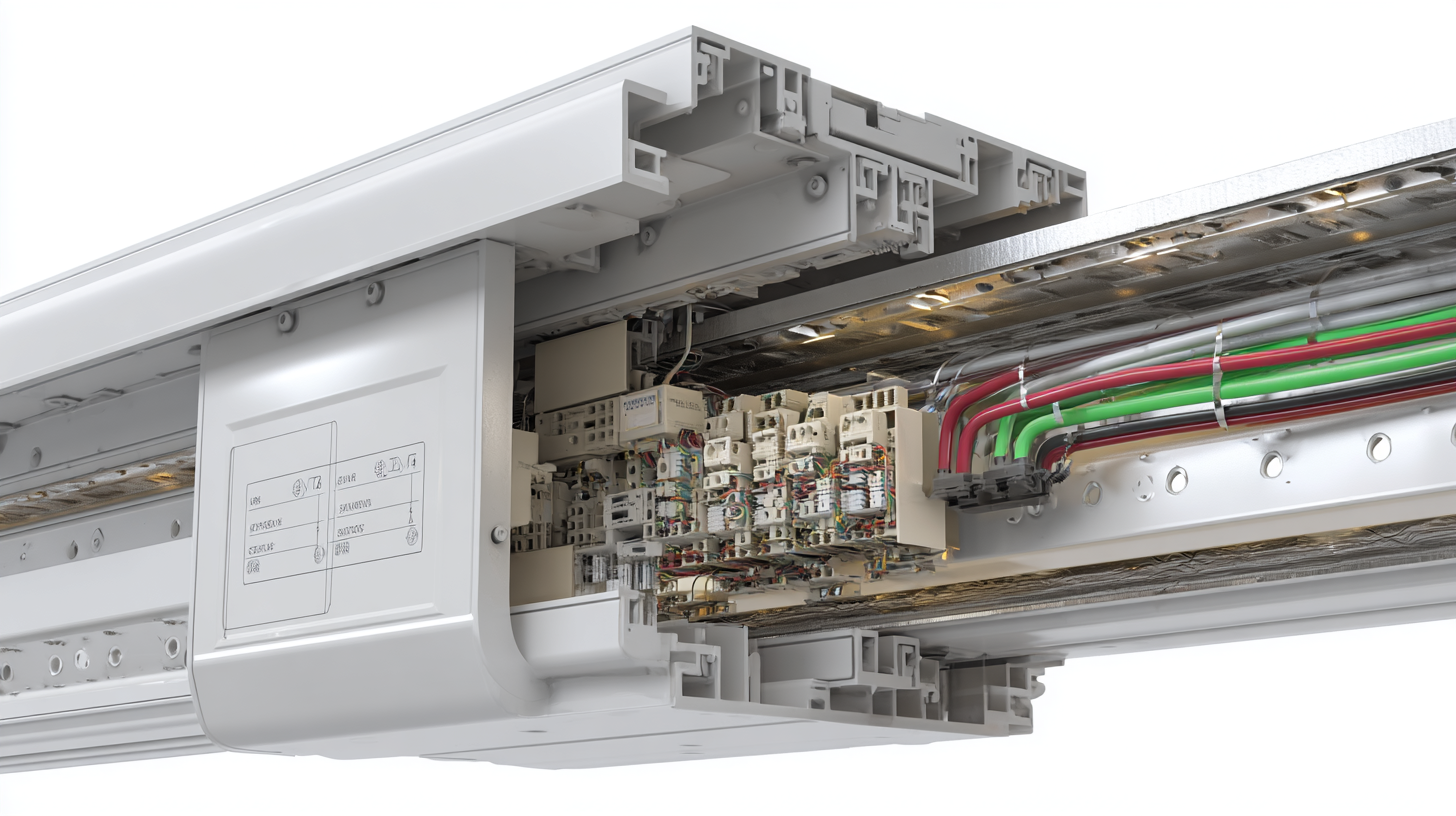

Understanding the various specifications and features of air type busways is essential for selecting the right system that meets your needs. Air type busways are widely recognized for their efficiency and effective heat dissipation, making them ideal for commercial and industrial applications. Key specifications to consider include the current carrying capacity, temperature rise, and the material composition of the busway. Depending on the design, busways can handle different load requirements and environmental conditions, which should be matched with your operational demands.

In addition to these specifications, features such as modularity, ease of installation, and maintenance need to be evaluated. A modular design allows for flexibility and scalability, enabling users to adjust the system as their power needs evolve. Moreover, air type busways typically require less maintenance compared to traditional wiring methods, saving time and costs in the long run. Understanding both the technical specifications and practical features will empower you to make an informed decision when upgrading or installing a busway system, ensuring you choose the optimal solution for your facility's electrical infrastructure.

This chart represents some key specifications of air type busways, including their current and voltage ratings, length, and weight. Understanding these specifications can help in selecting the right busway for your electrical distribution needs.

The evolution of electrical distribution systems has brought about significant advancements, particularly the emergence of air type busway systems. According to a report by MarketsandMarkets, the global busway market is projected to reach USD 8.21 billion by 2026, growing at a CAGR of 5.9% from 2021. This growth is largely attributed to the increased demand for efficient power distribution and the need for space-saving solutions in urban infrastructures.

While traditional busway systems have long been the go-to option for many applications, air type busways offer distinctive advantages in terms of thermal management and maintenance overhead, making them an appealing alternative.

In a comparative analysis, air type busways have been found to provide better heat dissipation, which is critical in high-load applications. A study published by the International Electrotechnical Commission (IEC) indicates that air-cooled busways can operate at higher current capacities with lower temperature rise, enhancing system reliability. Additionally, the flexibility of installation and the reduced need for extensive ducting or enclosures in air type systems offer a significant advantage in terms of installation costs and time. As industries increasingly focus on optimizing space and efficiency, understanding these differences will guide companies in selecting the right busway system tailored to their specific needs.

When considering air type busways, energy efficiency metrics play a crucial role in optimizing performance and reducing operational costs. A recent report from the International Energy Agency (IEA) indicates that utilizing advanced busway systems can lead to energy savings of up to 30% compared to traditional wiring methods. This substantial reduction is largely due to lower resistive losses and more efficient designs that facilitate higher current ratings without excessive thermal losses.

In addition, the National Renewable Energy Laboratory (NREL) highlights that implementing air type busways can enhance the overall system reliability, which further contributes to energy efficiency. By minimizing energy losses in conversion and distribution, facilities can maintain optimal operational conditions while also adhering to stringent sustainability goals. These enhancements make air type busways an attractive option for industries aiming to reduce their carbon footprints and implement greener practices.

When selecting the right Air Type Busway for your project, several critical factors come into play. First, consider the current rating and application requirements. The most common ratings for air type busways typically range from 100A to 5000A, catering to various industrial and commercial needs. According to recent industry reports, proper sizing directly affects energy efficiency and operational costs, leading to significant savings in high-demand applications. Therefore, accurately assessing your current needs is paramount.

Tip 1: Always calculate the maximum load your busway will need to handle, including any potential future expansions. Opting for a busway with a higher rating than currently necessary can provide a buffer, ensuring reliability during peak usage.

Next, consider the environment in which the busway will be installed. Factors such as temperature, humidity, and exposure to contaminants significantly impact the material selection. For instance, busways installed in outdoor applications may require additional weatherproofing or corrosion-resistant materials. Industry standards suggest that proper environmental considerations could enhance the lifespan of busway systems by up to 30%.

Tip 2: Conduct an environmental assessment before finalizing your choice. This ensures that you select a busway designed specifically for the adverse conditions it may encounter.

Finally, evaluate the installation and maintenance requirements of the busway system. Simplified installations can lead to reduced labor costs and shorter downtimes. Recent statistics indicate that systems designed for ease of installation can cut labor time by up to 20%.

Tip 3: Choose systems that offer modular components for easier expansion and maintenance, ensuring seamless upgrades in the future.

| Specification | Value | Importance Factor | Typical Applications |

|---|---|---|---|

| Current Rating | 1000A | High | Commercial Buildings |

| Voltage Rating | 400V | Medium | Industrial Applications |

| Length | 3 meters | Medium | Warehouses |

| Material | Aluminum | High | Power Distribution |

| Temperature Rating | -20°C to 40°C | Medium | Indoor Environments |

| IP Rating | IP20 | Medium | Control Panels |

Case studies provide valuable insights into the successful implementation of air type busway solutions across various industries. For instance, a leading automotive manufacturer faced challenges with energy distribution in its expansive production facility. By switching to an air type busway system, they achieved significant improvements in energy efficiency and flexibility, allowing for easier modifications as production needs changed. The modular design facilitated quick installation and reduced maintenance downtime, resulting in enhanced operational efficiency.

Case studies provide valuable insights into the successful implementation of air type busway solutions across various industries. For instance, a leading automotive manufacturer faced challenges with energy distribution in its expansive production facility. By switching to an air type busway system, they achieved significant improvements in energy efficiency and flexibility, allowing for easier modifications as production needs changed. The modular design facilitated quick installation and reduced maintenance downtime, resulting in enhanced operational efficiency.

Another notable example is a major retail chain that upgraded its lighting and HVAC systems using air type busways. The transition not only optimized the energy consumption of their facilities but also improved the overall aesthetic by minimizing cable clutter. This strategic move led to a 25% reduction in energy costs, showcasing the potential of air type busways in enhancing both functionality and visual appeal. These case studies highlight the effectiveness of air type busways in fostering innovation and sustainability in various sectors, proving their value as a modern solution for energy distribution.