Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

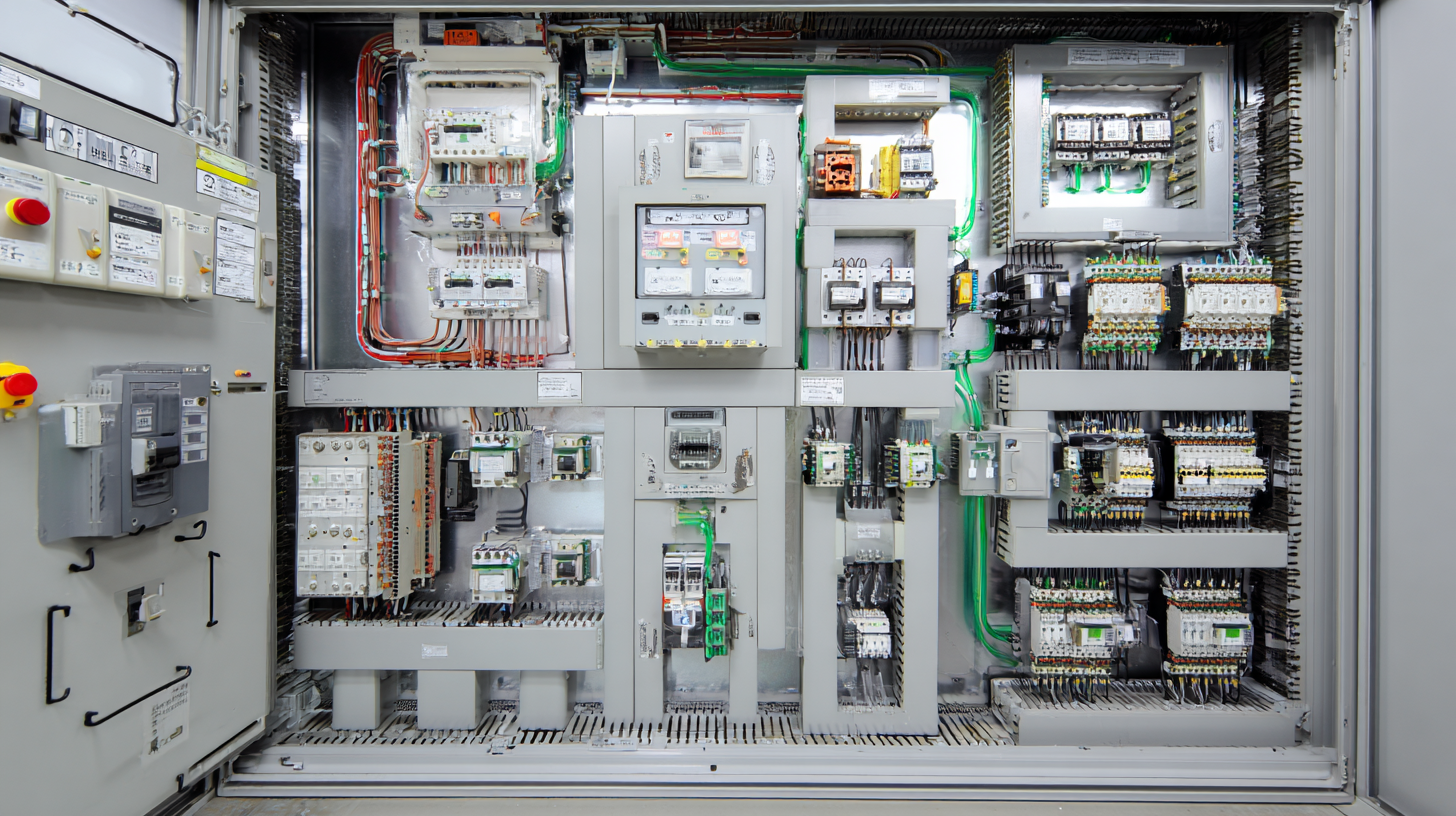

In today's fast-paced industrial landscape, the demand for efficient and reliable power distribution systems has never been greater. Among the various solutions available, the Copper Dense Busway stands out as a pivotal advancement in electrical infrastructure. This innovative technology offers distinct advantages that enhance the effectiveness of power distribution, making it an essential choice for modern facilities aiming to maximize performance while minimizing costs.

The Copper Dense Busway excels in its capacity to deliver electricity with reduced energy losses and improved safety features, catering to the needs of dynamic environments across various sectors. As industries continue to evolve, integrating advanced solutions like Copper Dense Busway becomes crucial to ensure not only operational efficiency but also sustainability. In this article, we will explore the top five benefits of utilizing Copper Dense Busway, highlighting its role in revolutionizing power distribution and supporting the growth of contemporary electrical systems.

Copper dense busway systems are gaining recognition in electrical power distribution due to their exceptional electrical conductivity. This enhanced conductivity allows for minimized power loss during transmission, ensuring that more energy reaches its intended destination. By utilizing copper as the primary conductor material, facilities can achieve higher efficiency levels, translating to cost savings over time. This is especially beneficial in large industrial applications where maximizing energy use is crucial.

In addition to efficiency, the thermal management capabilities of copper dense busway further contribute to their advantages. Copper can dissipate heat more effectively than many other materials, reducing the risk of overheating and increasing the overall longevity of the system. The robust nature of copper also means that these busways can handle higher current loads compared to aluminum counterparts, making them suitable for high-demand environments. With these benefits, businesses can not only enhance their energy efficiency but also ensure reliable and durable power distribution solutions.

The integration of copper dense busway systems in power distribution has revolutionized the way utilities manage space and efficiency in large facilities. Unlike traditional wiring methods, busway solutions optimize space by consolidating multiple conductors into a compact unit, effectively reducing the physical footprint required for power distribution. According to a report by the International Energy Agency (IEA), facilities utilizing busway technology can save up to 30% in installation space compared to conventional systems, thereby maximizing the usability of floor layouts in industrial and commercial settings.

Moreover, copper's superior conductivity ensures that these systems maintain high efficiency levels while minimizing energy loss. A study published in the Journal of Electrical Engineering indicated that copper busways can achieve electrical efficiency ratings exceeding 95%, significantly enhancing overall system performance. As more organizations seek sustainable energy solutions, the adoption of copper dense busway systems becomes not only beneficial but essential for meeting the demands of modern infrastructure.

**Tip 1:** Consider engaging with a professional to evaluate your facility's design for optimal busway integration, ensuring maximum space utilization and efficiency.

**Tip 2:** Regular maintenance of your busway system can prevent unexpected failures, further enhancing both safety and system longevity—a critical aspect for facilities aiming to achieve long-term operational success.

| Benefit | Description | Space Efficiency | Cost Savings |

|---|---|---|---|

| Compact Design | Less space required compared to traditional systems. | High | Reduces installation space. |

| Flexibility | Easily adaptable to changes in layouts. | Medium | Avoids costly redesigns. |

| Ease of Installation | Quick assembly and connection processes. | High | Decreases labor costs. |

| Higher Current Ratings | Suitable for high-capacity power distribution. | High | Optimizes use of existing infrastructure. |

| Reduced Maintenance | Requires less upkeep and inspections. | Medium | Saves on long-term operational costs. |

| Safety Features | Designed with safety compliance in mind. | High | Minimizes risk of failures. |

| Enhanced Performance | Improved energy efficiency and distribution. | High | Reduces energy consumption costs. |

| Environmental Friendly | Copper is recyclable with a lower environmental impact. | Medium | Promotes sustainability. |

| Versatile Applications | Suitable for various industries, including commercial and industrial. | High | Flexible integration into different setups. |

| Aesthetic Integration | Neat appearance, can blend with existing infrastructure. | Medium | Enhances overall facility design. |

The use of copper dense busway systems in power distribution presents significant long-term financial advantages, making them an attractive option for businesses seeking efficiency and cost savings. One of the primary benefits of copper busways is their reduced operational costs over time. Copper, known for its superior electrical conductivity, minimizes energy loss during transmission, resulting in lower electricity bills. Additionally, these systems require less maintenance compared to traditional wiring methods, further contributing to financial efficiency.

Moreover, copper dense busways are durable and have a longer lifespan, which translates to lower replacement costs. This reliability not only enhances the efficiency of power distribution but also supports sustainable practices by reducing waste associated with frequent replacements. As businesses invest in copper dense busway technology, the cumulative savings from reduced energy consumption and maintenance can significantly impact their bottom line, ultimately leading to a more economically viable power distribution solution.

This chart illustrates the various benefits of using Copper Dense Busway for efficient power distribution. Each benefit is scored on a scale from 1 to 10 based on its impact, showcasing significant advantages like cost savings, energy efficiency, and high conductivity.

Efficient heat management is crucial in modern power distribution systems, and copper dense busway systems excel in this regard. Utilizing copper's excellent thermal conductivity, these busways effectively dissipate heat generated by power flow. This characteristic minimizes the risk of overheating, which can lead to equipment failure and costly downtime. By maintaining lower operating temperatures, copper dense busways enhance the reliability of electrical systems, allowing them to operate at optimal performance levels.

Moreover, the design of copper dense busways can be tailored to improve airflow and facilitate better cooling mechanisms. With their compact and modular nature, they allow for innovative layouts that can maximize cooling efficiency in complex environments. This improved heat management not only prolongs the lifespan of electrical components but also supports continuous operation, which is vital in critical applications where power supply reliability is a top priority. Consequently, companies can achieve greater energy efficiency and lower maintenance costs, making copper dense busways an ideal choice for modern power distribution challenges.

Efficient power distribution is critical in today’s industrial landscape, and using copper dense busway systems offers significant advantages in maintenance and accessibility. According to a report by the International Electrical and Electronics Engineers (IEEE), busway systems can reduce maintenance times by up to 30% compared to traditional wiring methods. This reduction is largely due to the streamlined design of busway systems, which allows for quicker access to electrical components. As maintenance personnel can easily reach and assess the system without extensive disassembly, troubleshooting becomes simpler and less time-consuming.

Moreover, the robust design of copper dense busways contributes to their reliability, allowing facilities to minimize downtime. A study conducted by the National Electrical Manufacturers Association (NEMA) found that busway systems can handle higher power loads with lower voltage drops, leading to improved performance and reduced wear and tear on the system. This characteristic not only enhances the lifespan of the electrical infrastructure but also facilitates straightforward inspections and repairs, further emphasizing their role in simplifying maintenance tasks in complex power distribution setups.