Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

In the realm of electrical systems, the Bus Bar is gaining recognition. It serves as a vital component for power distribution. Many industries rely on it for efficiency and reliability.

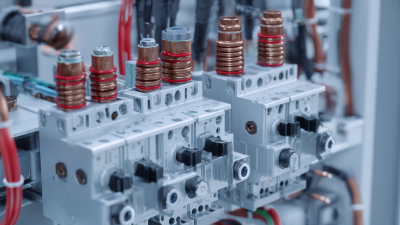

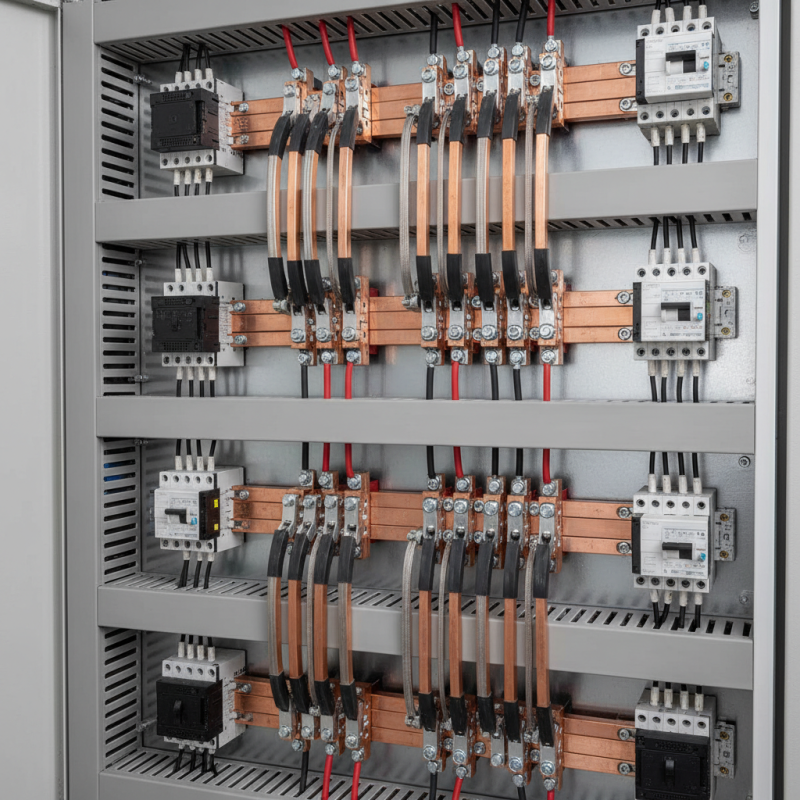

Bus Bars come in various forms. They are often made of copper or aluminum. Their design allows for flexible connections in complex systems. These features enhance overall performance. However, not all Bus Bars are created equal. The choice between materials can impact conductivity and longevity.

Adopting Bus Bars presents numerous benefits and challenges. While they improve space utilization, improper installation may lead to issues. This highlights the need for careful planning and execution. A Bus Bar can transform how we manage electricity, but it demands attention to detail. Reflecting on these aspects can lead to better outcomes in electrical design.

Bus bars are crucial for efficient power distribution in electrical systems. They provide a compact and organized solution for transferring electrical power with minimal losses. According to a report by the International Energy Agency, improper power distribution can lead to losses of up to 30%. By utilizing bus bars, facilities can significantly reduce these losses. Their design allows for optimal heat dissipation, prolonging the lifespan of electrical components.

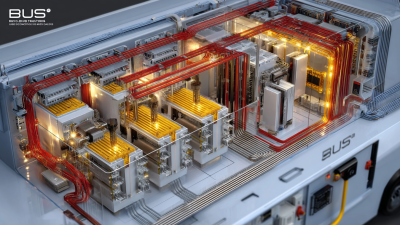

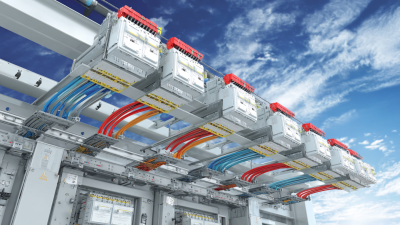

Moreover, bus bars offer flexibility in high-density environments. Their modular design suits various installations. For instance, data centers often face space constraints. Bus bars can be customized to fit in limited areas while still meeting power demands. Interestingly, a study by the Electrical Power Research Institute shows that implementing bus bars can increase system reliability by 20%.

However, there's a common misconception regarding their usage. Some believe that bus bars are only for large facilities. This is not entirely accurate. They are beneficial for smaller systems too. Overlooking this aspect can lead to inefficient setups. Bus bars not only streamline power distribution but also enhance safety through simplified wiring complexity.

Bus bars have become crucial components in modern electrical systems, enhancing safety features significantly. They offer a robust alternative to traditional wiring systems. With proper installation, bus bars can reduce the risk of overheating and electrical fires. According to industry reports, nearly 40% of electrical failures stem from poor connections in wiring setups. This highlights the importance of secure, reliable bus bars.

Using bus bars can also facilitate easier maintenance. Their design allows for easier access during inspections. This means that potential issues can be identified before they escalate. A proactive approach can lower overall costs. An industry report revealed that proper maintenance could decrease operational failures by up to 30%.

**Tips**: Ensure you regularly inspect your bus bar connections. Look for signs of wear or corrosion. Maintain a clean environment around bus bars to prevent dust buildup. Education and training on safety standards are essential for teams handling electrical systems. Awareness of the potential hazards can prevent accidents. Remember, investing in safe solutions is never a waste.

Bus bars play a crucial role in electrical systems, especially in industrial applications. They are metal strips or bars that distribute electrical power efficiently. One of the main advantages is cost-effectiveness. Installing bus bars can significantly reduce installation costs compared to traditional wiring methods. The initial setup might require investment, but the long-term savings are notable. They help in minimizing material costs and labor hours.

Bus bars are also easier to maintain. Their design allows for quick inspections and repairs. This can save both time and money, a precious resource in industrial settings. While some may argue that switching to bus bars requires adjustments, the benefits often outweigh these concerns. Over time, users may find fewer connections to check, reducing points of potential failure.

One unexpected benefit is their capacity for high current loads. Companies might underestimate their efficiency in handling heavy loads. Yet, this capacity means fewer components are needed. Some industries may overlook this advantage and stick with older wiring systems. Reflecting on these factors can provide a clearer picture of the value bus bars add to cost-effectiveness in industrial applications.

Bus bars are revolutionizing electrical systems. They enhance performance and reliability significantly. A recent industry report reveals that systems using bus bars can improve energy efficiency by up to 20%. This reduction is critical in large facilities where energy costs are substantial.

Using bus bars also minimizes heat generation. This is crucial as excess heat can harm components. Properly designed bus bars can operate at lower temperatures, extending the lifespan of electrical systems. Industry experts found that without adequate heat management, electrical failures increase by 30%.

Tip: Regularly inspect bus bar connections to ensure optimal performance. Proper maintenance can catch early signs of corrosion or wear.

Bus bars simplify wiring configurations. They reduce the complexity of connections, allowing for easier modifications. However, improper installation can lead to serious issues. Conducting thorough training for installation teams is vital. Reports indicate that poorly installed bus systems can increase downtime by 25%.

Tip: Use thermal imaging to check for hotspots in bus bar systems. This proactive approach can prevent failures.

| Benefit | Description |

|---|---|

| Improved Reliability | Bus bars minimize connection points and improve overall system reliability. |

| Increased Current Carrying Capacity | Bus bars can carry larger currents than traditional wire connections, reducing voltage drop. |

| Space Efficiency | Bus bars take up less space than cables, allowing for more compact design. |

| Lower Installation Cost | Simpler installation processes reduce labor costs associated with fitting and connections. |

| Reduced Heat Generation | Efficient current flow reduces heat loss, enhancing energy efficiency. |

| Easier Maintenance | Bus bars are easier to access and maintain compared to complex wiring systems. |

| Improved Safety | Bus bars often have better insulation and grounding properties, enhancing safety. |

| Scalability | Bus bar systems can be easily expanded or modified for future needs. |

| Aesthetic Appeal | Their compact and orderly design can enhance the appearance of electrical systems. |

| Versatility | Bus bars can be used in a wide range of applications from power distribution to renewable energy systems. |

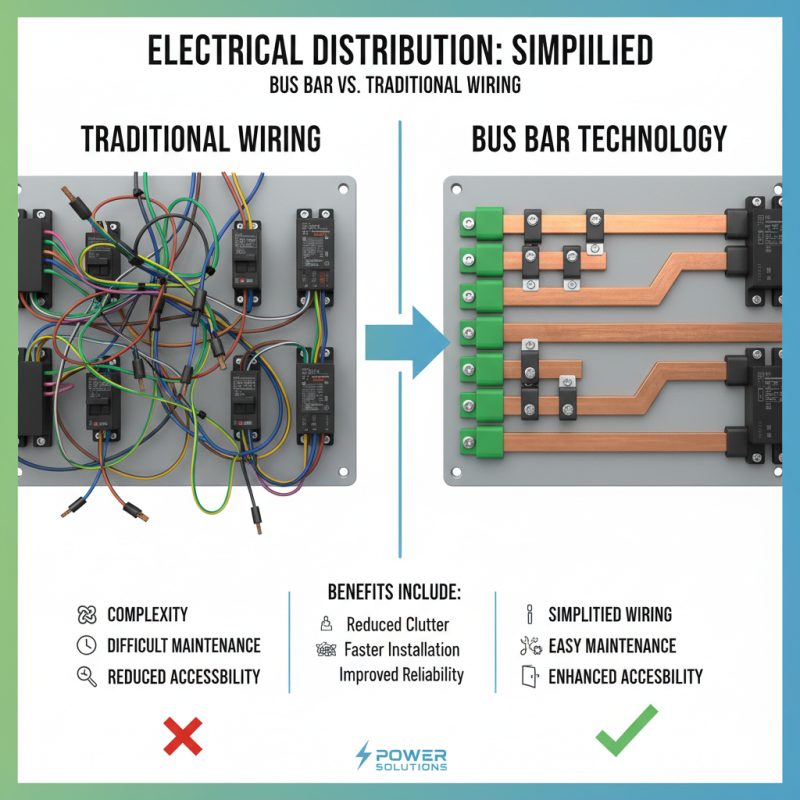

Bus bar technologies bring several benefits, particularly in simplifying wiring and maintenance. Using bus bars instead of traditional wiring reduces the complexity of electrical connections. They serve as a central point for electrical distribution, minimizing the number of cables needed. This creates a neater installation and enhances accessibility.

Maintenance becomes less daunting with bus bars. They typically require fewer connections, which reduces potential failure points. The enclosed design protects against dust and moisture. This feature makes routine inspections easier. Technicians can quickly identify any issues, speeding up repairs.

However, some may overlook the need for proper planning. Inadequate design can lead to overcrowding in the electrical panels. It's essential to consider that space is a factor. Moreover, not all bus bar materials have the same longevity. Choosing the right one is crucial. It’s a balancing act between cost, durability, and application.