Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

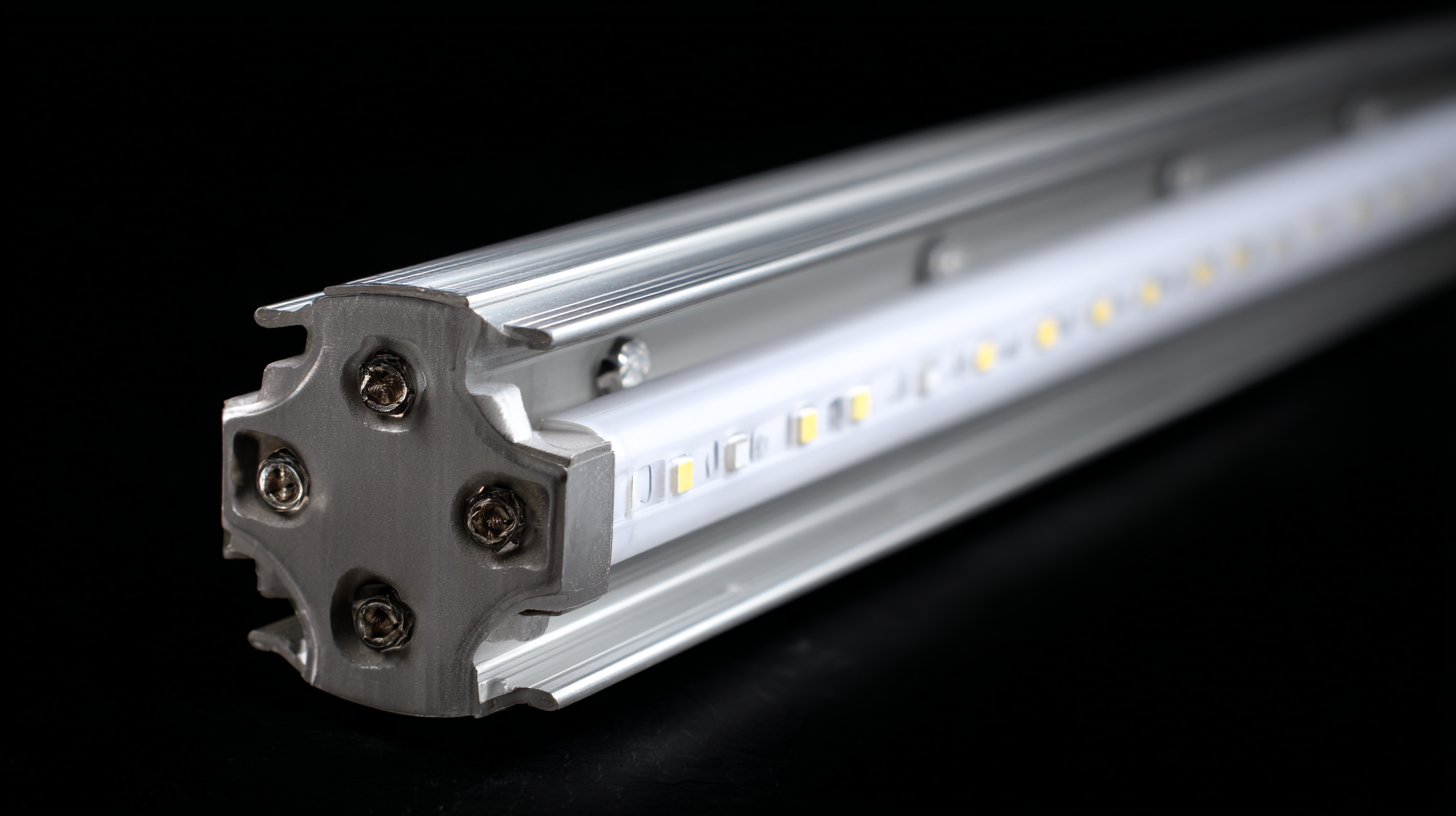

In the rapidly evolving landscape of power distribution, the quest for efficiency and reliability has led to the emergence of innovative solutions such as the Aluminum Dense Busway. As power demands continue to escalate, industry reports indicate that the global busway market is projected to reach USD 10.29 billion by 2027, growing at a CAGR of 6.5%. The Aluminum Dense Busway, characterized by its lightweight, high conductivity, and compact design, provides a robust solution for minimizing energy loss and enhancing overall system performance. By effectively channeling electricity while reducing installation space and costs, this technology proves essential in modern electrical systems, particularly in data centers and industrial applications where efficiency is paramount. Understanding how to leverage the benefits of Aluminum Dense Busway can significantly optimize power distribution infrastructure, ultimately supporting sustainability and operational excellence in the energy sector.

Aluminum dense busway systems play a pivotal role in enhancing energy efficiency within power distribution networks. According to a report by the International Energy Agency (IEA), optimizing power distribution infrastructure can lead to energy savings of up to 10-15%, making these systems not only cost-effective but also environmentally friendly. Aluminum, with its lower electrical resistance compared to traditional copper options, enables more efficient power transfer, resulting in reduced energy losses. This translates into lower operational costs for businesses utilizing these advanced systems.

Tip: When considering the implementation of aluminum dense busway systems, it is crucial to analyze your facility’s specific energy demands to tailor the busway design for maximum efficiency.

Furthermore, aluminum's lightweight nature facilitates easier installation and reduces labor costs, which is particularly beneficial in retrofitting existing systems. The thermal management properties of aluminum also minimize overheating risks, significantly enhancing the reliability and lifespan of power distribution systems. As per the U.S. Department of Energy, effective thermal management can decrease equipment failure rates by up to 30%, further validating the shift toward aluminum dense busways in modern infrastructures.

Tip: Regular maintenance checks on your aluminum dense busway can help identify potential issues early, ensuring uninterrupted operation and enhanced energy efficiency.

When evaluating the efficiency of power distribution systems, the choice between aluminum dense busways and traditional copper busbars is crucial. Aluminum dense busways offer distinct advantages, primarily due to their lighter weight and lower cost. This translates into easier installation and reduced labor expenses. Additionally, aluminum has a higher resistance to corrosion, which enhances the longevity of the distribution system, especially in harsh environments. Moreover, the trend toward compact and modular designs makes aluminum busways particularly attractive for modern power distribution needs.

In contrast, copper busbars, while traditionally known for their conductivity and durability, come with higher material costs and increased weight. This may lead to greater installation complexity and increased structural requirements for support. Furthermore, copper’s propensity to corrode under certain conditions necessitates additional protective measures, which can add to maintenance expenses over time. Therefore, in applications seeking improved efficiency, reduced costs, and ease of installation, aluminum dense busways present a compelling alternative to conventional copper solutions. The comparative analysis of these materials highlights the importance of choosing the right busway for optimized power distribution in contemporary electrical systems.

The cost-effectiveness of aluminum dense busway systems in large-scale power installations has become increasingly significant in the energy sector. Recent industry reports suggest that aluminum can offer up to 30% savings in material costs compared to traditional copper bus systems. This is largely due to aluminum's lower density, making it more cost-efficient to transport and install without compromising conductivity. According to a report by the International Energy Agency, implementing aluminum busways can lead to a reduction of total lifecycle costs by approximately 15%, highlighting their long-term financial advantages.

Additionally, with aluminum's remarkable thermal performance, large installations can benefit from reduced heat generation, which in turn enhances the overall efficiency of the power distribution network. A study by the National Renewable Energy Laboratory indicates that optimizing thermal management through the use of aluminum busways can enhance energy efficiency by up to 10%. This dual benefit of immediate cost savings and long-term operational efficiency positions aluminum dense busway systems as a viable choice for modern power distribution infrastructures, ultimately driving down costs while supporting sustainable energy practices.

Aluminum dense busway systems play a crucial role in modern energy distribution, particularly in their ability to significantly reduce the carbon footprint of power systems. By utilizing lightweight aluminum instead of traditional copper, these systems not only decrease material use but also enhance energy efficiency. The lower weight of aluminum facilitates easier installation and reduces transportation emissions, thus contributing to a smaller environmental impact from the outset.

Furthermore, aluminum dense busways are designed to minimize energy losses through their superior conductivity and heat dissipation capabilities. This efficiency ensures that more electricity reaches the end-users without unnecessary waste, leading to a reduction in overall energy consumption. As power plants and industrial facilities increasingly adopt these efficient systems, the cumulative effect contributes meaningfully to lowering greenhouse gas emissions throughout the energy supply chain.

The shift towards aluminum dense busways demonstrates an effective approach to advancing sustainability in energy systems while meeting the growing demand for efficient power distribution.

Aluminum dense busway systems offer remarkable design flexibility and scalability, making them ideal solutions for evolving power needs in high-efficiency power distribution systems. One of the primary advantages of these busways is their modular design, which allows for easy expansion and reconfiguration as electrical loads change over time. This adaptability is crucial for businesses anticipating growth or shifts in energy demand, as they can increase capacity without the need for extensive system overhauls.

Moreover, the lightweight nature of aluminum enhances installation efficiency and reduces the structural requirements of support systems. This flexibility enables engineers to optimize layouts based on the unique configurations of their facilities, maximizing space utilization while ensuring safe and efficient power distribution. As industries continue to adopt advanced technologies and renewable energy sources, the scalability of aluminum dense busway systems ensures that facilities can seamlessly integrate new systems and technologies, responding dynamically to future power needs without compromising performance or reliability.