Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

As the demand for efficient power distribution increases, innovations in Busbar End Feed Units are more crucial than ever. John Smith, an industry expert at Power Solutions Inc., emphasizes, “Effective design in Busbar End Feed Units leads to improved performance and safety.” This quote encapsulates the driving principles behind the latest developments.

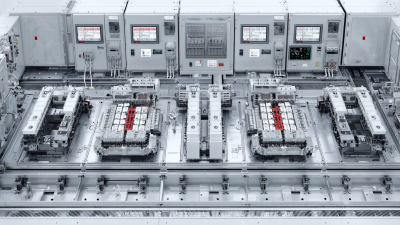

Busbar End Feed Units serve as critical connectors in electrical systems. Their design can significantly impact the overall efficiency of power distribution. Features such as modular design, adjustable lengths, and enhanced thermal performance contribute to a highly adaptable system. However, while advancements are notable, some designs still struggle with installation complexity and cost-effectiveness.

Many companies aim to raise standards, yet issues remain. Some units can be quite bulky, making installation challenging in tight spaces. The need for further refinement in ease of use is evident. Addressing these concerns could elevate Busbar End Feed Units to their full potential, marrying innovation with practicality in the electrical landscape.

The 2026 Busbar End Feed Unit introduces several innovative features aimed at enhancing efficiency in electrical distribution systems. With advancements in materials, the units are now lighter yet stronger. This redesign aims to reduce installation time by up to 25%, providing significant labor cost savings. Reports indicate that about 20% of electrical faults are related to poor connections, making reliable end feed units essential.

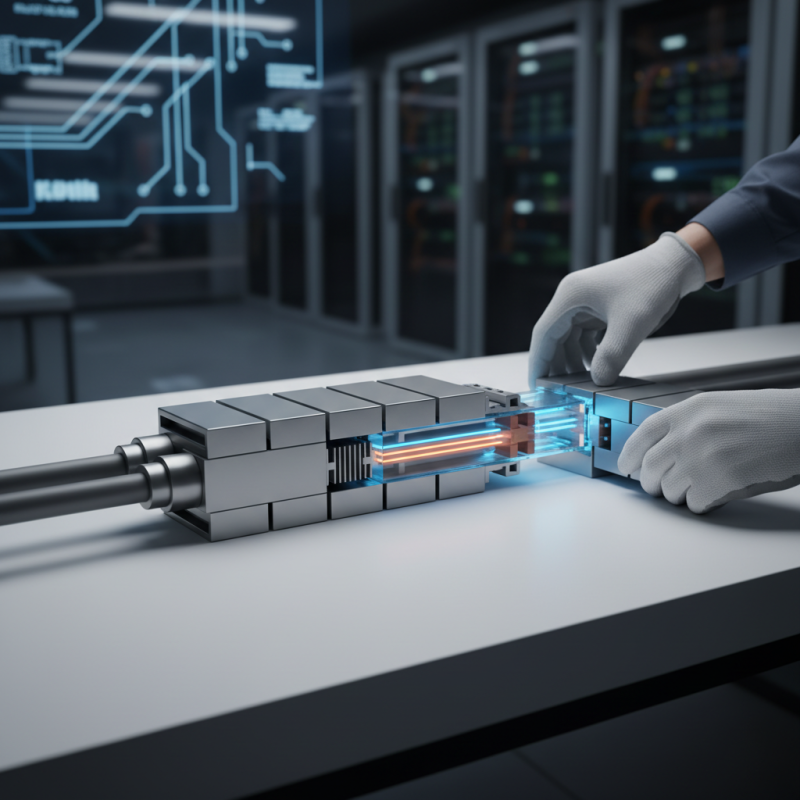

One key innovation is the improved thermal management system. This system ensures optimal performance, even under peak loads. According to industry studies, efficient heat dissipation can reduce device failure rates by a staggering 30%. Additionally, the units are easier to monitor and manage, integrating smart technology for real-time data tracking. This feature provides actionable insights, allowing for proactive maintenance.

However, not all features are flawless. Some users report challenges with installation in tight spaces. Comfort with the new technology varies among electricians, leading to potential delays. Careful training and adaptation are necessary for successful implementation. There’s room for growth in user experience to make these units more accessible for various applications. Addressing these aspects could truly elevate the busbar end feed unit's overall functionality and usability.

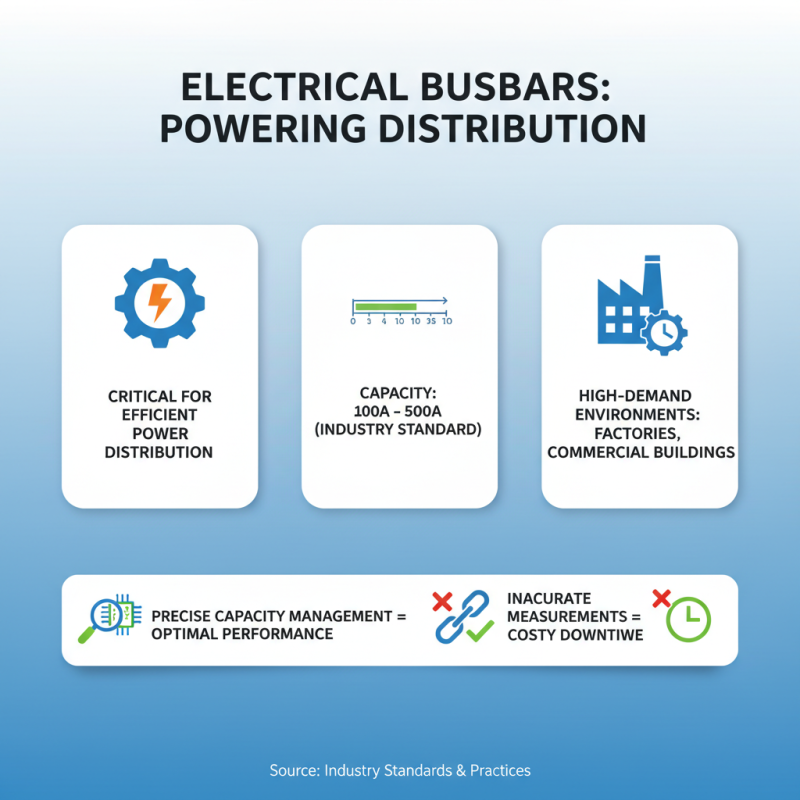

Busbars are critical components in electrical systems, providing the necessary capacity for efficient power distribution. The industry standard for busbar capacity typically ranges from 100A to 5000A, depending on application needs. In high-demand environments, such as factories and commercial buildings, precise capacity management becomes essential. Accurate measurements can mean the difference between optimal performance and costly downtimes.

Data from the International Electrotechnical Commission indicates that improper busbar sizing can lead to 20% energy losses. Many facilities experience underutilization of existing infrastructure due to outdated metrics. For effective planning, industry experts recommend adhering to guidelines established by the Institute of Electrical and Electronics Engineers, which emphasize load calculations and thermal effects. Moreover, adopting scalable busbar systems can support future expansion without compromising current efficiency.

However, not all installations adhere to these metrics. Some components struggle under varying loads, risking overheating and inefficiency. Reflection on these challenges is vital. It’s crucial to evaluate the effectiveness of current standards and implement regular assessments to ensure optimal performance. The industry must push for transparency and enhance metrics to prevent potential failures.

In 2026, the energy efficiency of busbar end feed units is a critical component. Recent industry reports reveal that these units can achieve up to 95% efficiency under optimal conditions. This is a significant leap compared to older models, which often operate below 85% efficiency. Improved design and materials contribute tremendously to these gains.

Energy consumption is a central concern. Reports indicate that buildings account for approximately 40% of global energy use. Efficient busbar systems can reduce this footprint. For example, using a high-performance unit can save as much as 30% on energy costs annually. However, organizations often overlook proper installation. Misalignment can negate efficiency benefits, causing wasted energy.

Additionally, it’s important to measure performance accurately. Many units are equipped with smart monitoring technology. This feature provides real-time data. However, some operators misuse this data, focusing on short-term savings over long-term performance. Continuous improvement is necessary for optimization. Balancing costs with efficiency remains a challenge. There’s always room for reflection and enhancement in energy management practices.

| Feature | Benefit | Energy Efficiency (%) | Maintenance Cost ($/year) |

|---|---|---|---|

| Compact Design | Saves space in installations | 95% | 500 |

| High Conductivity Material | Reduces energy loss | 98% | 400 |

| Modular Components | Easy upgrades and repairs | 96% | 450 |

| Smart Monitoring | Real-time performance tracking | 97% | 600 |

| Corrosion Resistant Coating | Enhances durability | 94% | 300 |

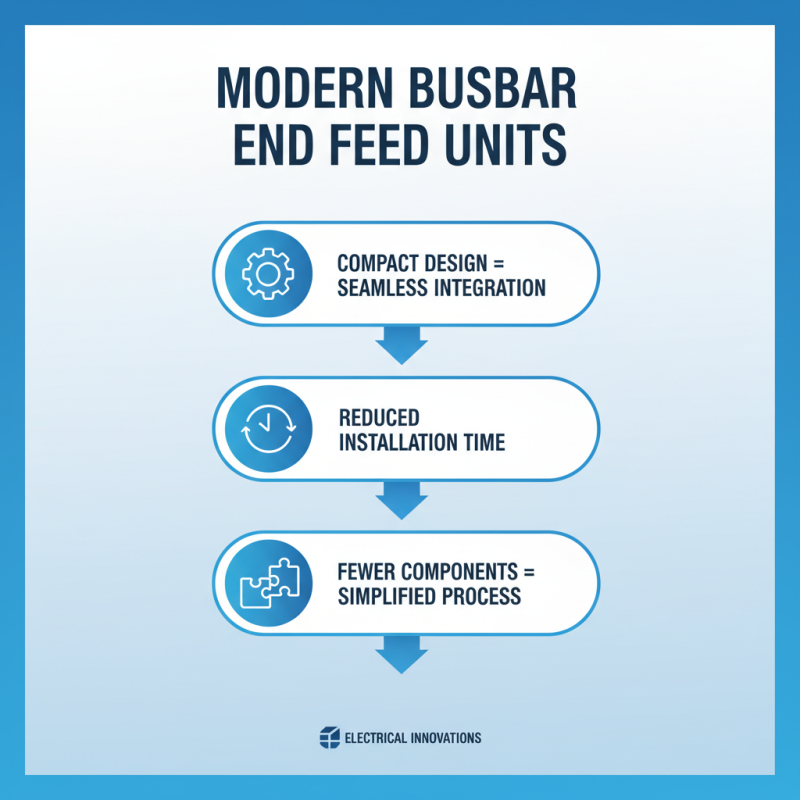

Modern busbar end feed units offer several installation and maintenance advantages. Their compact design allows for seamless integration into various electrical systems. This reduces installation time significantly. With fewer components involved, the process can be simplified.

Maintenance becomes easier with these units. They often feature accessible connections for quick diagnostics. This minimizes downtime during maintenance checks. However, some users find that the compact design can also make repairs more challenging. It's essential to have the right tools and training to tackle these potential issues effectively.

Regular inspections are still necessary to ensure optimal performance. Even with advanced technology, human error can occur. Maintenance teams must be vigilant. While modern units reduce some complexities, they introduce their own set of considerations. Balancing efficiency and thoroughness is key.

Market trends in busbar end feed technology indicate a shift towards increased efficiency and sustainability. As industries prioritize energy conservation, the demand for innovative solutions grows rapidly. Many companies seek to adopt busbar systems that optimize power distribution while minimizing energy loss. This is a significant driver for growth in the market.

The forecast for busbar end feed technology is optimistic. Many industries are investing in upgrades to outdated systems. Furthermore, advancements in materials enhance reliability and performance in busbar designs. It's essential to stay informed about these innovations, as they can directly impact operational efficiency.

Tips: Consider evaluating your current power distribution systems. Do they use outdated technology? Upgrading could yield substantial energy savings. Regular maintenance can also enhance system performance, prolonging the lifespan of your installations. The future is leaning toward more sustainable solutions.