Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

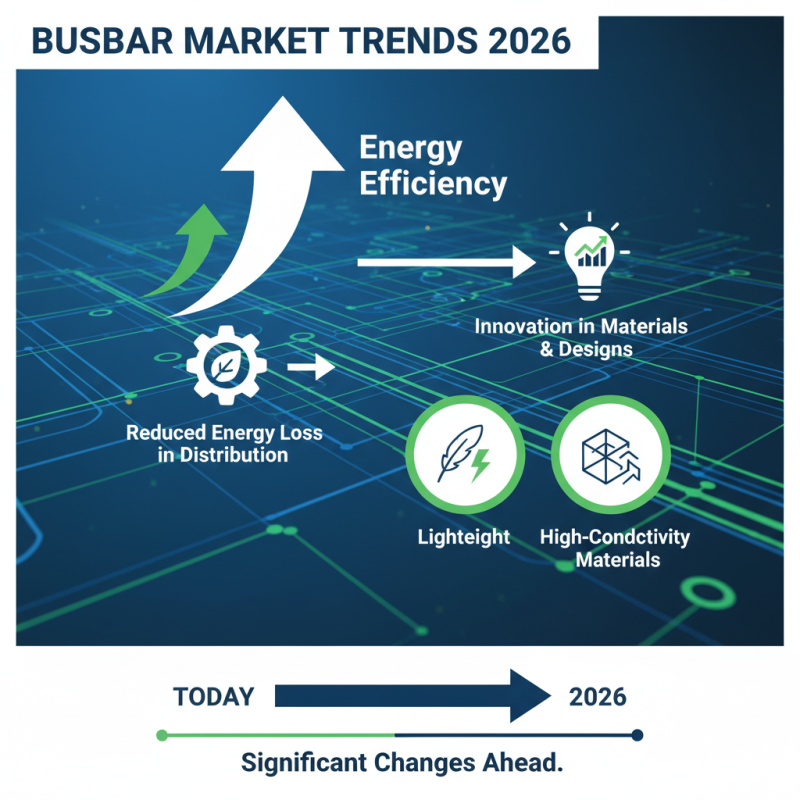

As industries evolve, Busbar Distribution remains a critical component in electrical infrastructure. According to a report by Allied Market Research, the global busbar market is projected to reach $24 billion by 2026, growing at a compound annual growth rate (CAGR) of 6%. This growth reflects the increasing demand for effective power distribution solutions in various sectors, including commercial and industrial applications.

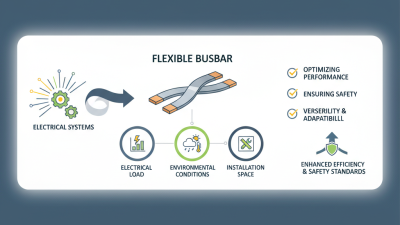

The landscape of Busbar Distribution solutions is shifting towards higher efficiency and safety standards. Leading manufacturers are investing in innovation, focusing on modular systems that enhance adaptability and reduce installation time. However, the transition to advanced technologies often encounters obstacles. Companies must navigate integration challenges with legacy systems and determine the best materials for their specific needs. For instance, copper and aluminum remain key materials, but their costs fluctuate widely, impacting project budgets.

Trends indicate a movement toward sustainable solutions in Busbar Distribution. The push for greener technologies is vital as the world prioritizes environmental responsibility. Yet, some organizations struggle to balance sustainability with economic feasibility. Addressing these issues is essential for future growth. The upcoming year will be pivotal for the sector as companies embrace these trends while reflecting on the complexities of implementing change effectively.

As we look towards 2026, busbar distribution solutions are evolving rapidly. The global busbars market is expected to reach $23.3 billion by 2026. This growth reflects increased demand for efficient power distribution in various sectors. Industries are focusing on sustainability while optimizing their energy consumption.

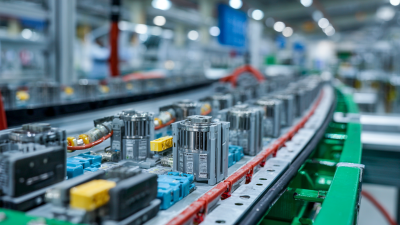

The complexity of modern electrical systems demands innovative busbar designs. Manufacturers are increasingly adopting modular busbar systems. These systems allow for easier installation and maintenance. Additionally, flexible busbar solutions offer adaptability in dynamic environments. However, these innovations come with challenges. Understanding heat dissipation, electromagnetic interference, and load management is critical. A recent report indicated that nearly 20% of installations face issues related to improper heat handling.

Data from industry analyses reveal that companies are investing heavily in advanced materials. These help enhance conductivity and durability. Yet, there’s a gap between innovation and practical application. Many professionals still lack training in handling sophisticated busbar technologies. This can lead to inefficiencies and safety concerns. As the landscape evolves, addressing these gaps will be crucial for maximizing the benefits of busbar distribution systems.

| Solution Type | Material Used | Maximum Current Rating (A) | Efficiency (%) | Market Trends |

|---|---|---|---|---|

| Standard Copper Busbars | Copper | 8000 | 95 | Increasing demand for energy efficiency |

| Aluminum Busbars | Aluminum | 5000 | 90 | Cost-effective solutions |

| Flexible Busbars | Copper/Aluminum Mix | 3000 | 92 | Adoption in compact designs |

| Insulated Busbars | Copper | 4000 | 94 | Focus on safety and reduced short circuits |

| High Voltage Busbars | Copper | 15000 | 96 | Growing in renewable energy sectors |

The busbar market is witnessing significant changes as we approach 2026. One prominent trend is the shift towards energy efficiency. Companies are looking to reduce energy loss in distribution systems. This shift prompts innovation in materials and designs. Lightweight, high-conductivity materials will likely emerge.

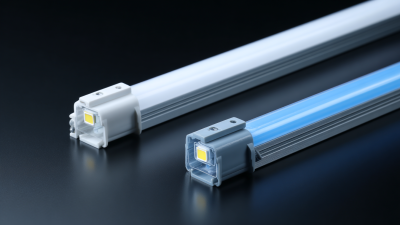

Another trend gaining traction is modular busbar systems. These systems offer flexibility in design and installation. Users can easily expand or adapt their systems to meet future needs. Such adaptability is essential for modern facilities. However, the challenge remains. Not all manufacturers provide clear guidelines for installation and maintenance, which can lead to inefficiencies.

Additionally, digital monitoring solutions are becoming vital. Incorporating IoT technology allows for real-time monitoring of busbar performance. This enhances operational reliability and safety. Yet, integrating these technologies can be complex. Many companies will need to invest time and resources to adapt. The lessons learned during this transition will shape future developments in the industry.

The busbar distribution sector is undergoing significant transformation. Innovative technologies are driving advancements in design and implementation. According to recent market reports, the busbar market is expected to reach $15 billion by 2026. This growth reflects a demand for efficiency and cost-effectiveness.

One of the key trends in busbar design is modularity. Modular busbar systems allow for easy expansion and customization. This flexibility helps companies adapt to changing energy requirements. Additionally, a recent survey indicated that 55% of companies prioritize sustainability in their busbar solutions. Smart materials, such as lightweight aluminum alloys, are becoming increasingly popular.

While these innovations are promising, challenges remain. Many companies still rely on outdated systems that do not meet current standards. Concerns about electrical safety and thermal management persist. Regular maintenance of busbar systems is often neglected, leading to efficiency losses. As the market evolves, addressing these issues will be crucial for success. Companies must invest in training and development to maximize the potential of new technologies.

Sustainability is becoming crucial in busbar distribution systems. Companies are increasingly focusing on eco-friendly practices. Reducing energy waste is a significant factor. Efficient busbar designs optimize energy flow and minimize losses. This helps lower the carbon footprint of electrical systems.

Proper material choices also matter. Using recyclable materials can enhance sustainability. Manufacturers explore aluminum and copper. These choices can lessen environmental impact while maintaining performance.

Tips: Regular maintenance of busbar systems can improve efficiency. Clean connections help reduce resistance. Monitor your energy consumption to identify areas of waste. Adopting these practices can lead to more sustainable operations. Remember, even small changes can make a difference.

The busbar industry faces significant challenges in 2026. Infrastructure upgrades are crucial, yet costly. Many manufacturers struggle to adapt to evolving regulations. As per industry reports, over 40% of busbar systems are outdated. This creates inefficiencies and safety risks.

Technological integration is another hurdle. The rise of digital solutions demands skilled labor. Yet, skilled professionals are scarce in this niche. A recent survey indicated that around 30% of companies report difficulty filling key positions. Moreover, the environmental impact of production needs attention.

Opportunities exist in innovative manufacturing. Advanced materials can improve efficiency and reduce costs. The market for eco-friendly busbars is growing rapidly. An estimated 25% increase in green solutions is expected by 2026. Companies that embrace sustainability can gain a competitive edge. However, change takes time. Transitioning may lead to temporary disruptions. Balancing tradition with innovation remains a complex issue.