Leave Your Message

-

Phone

-

E-mail

-

Whatsapp

-

Whatsapp

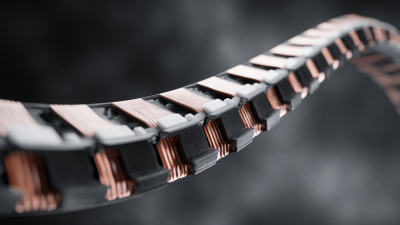

The evolving landscape of electrical distribution systems has witnessed significant advancements, particularly in the realm of Cast Resin Busbar technology. This innovation not only enhances the safety and reliability of power transmission but also offers a sustainable solution in an era where energy efficiency is paramount. According to industry reports, the global market for busbar systems is projected to reach $XX billion by 2025, with Cast Resin Busbar technology leading the charge due to its superior performance characteristics.

The top innovations in Cast Resin Busbar technology reveal a trend towards smart systems capable of real-time monitoring and enhanced connectivity. These developments are expected to reduce energy loss by up to XX% compared to traditional solutions, making them an economical choice for both industrial and commercial applications. Furthermore, with increasing regulatory pressures around sustainability, Cast Resin Busbars, which are typically more environmentally friendly, are rapidly being adopted in markets worldwide.

The following outline delves into the top 10 innovations in this dynamic field, showcasing the transformative potential of Cast Resin Busbar technology across diverse applications.

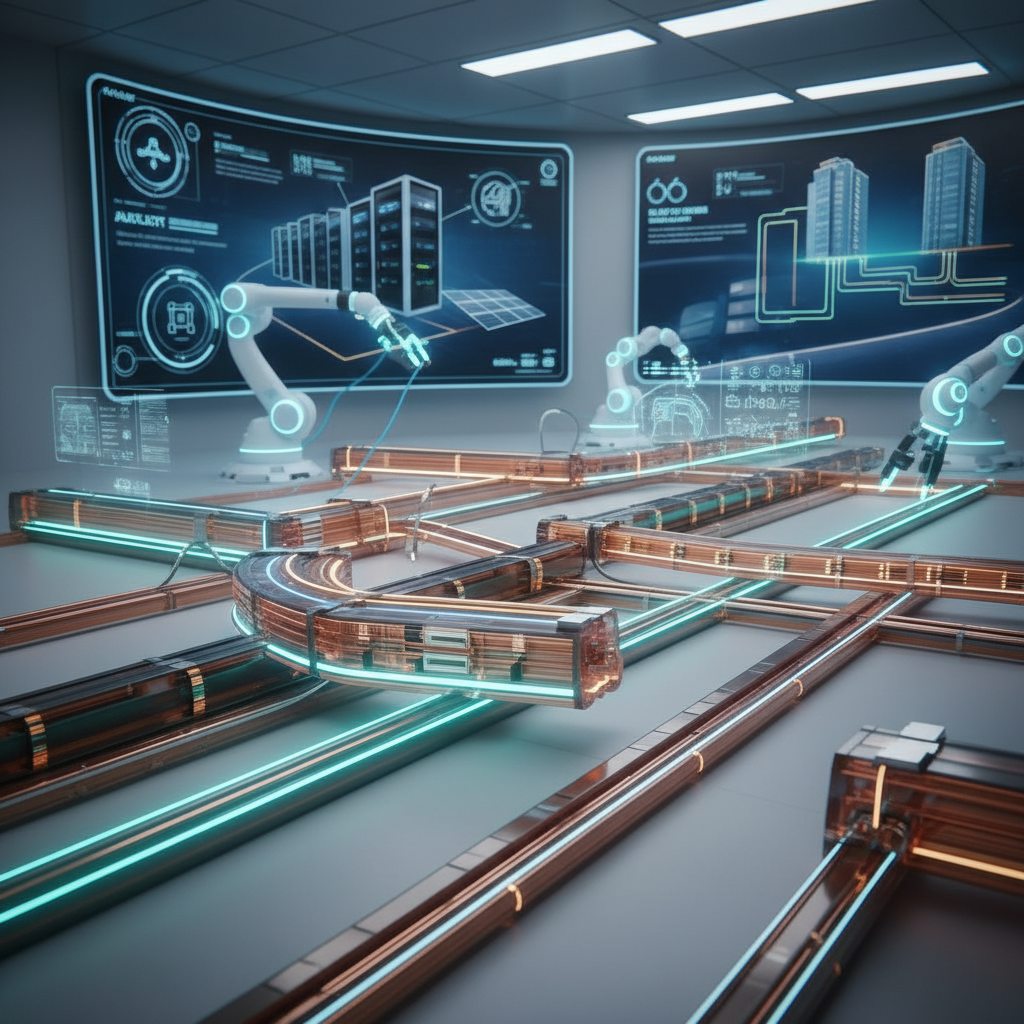

The year 2025 is poised to witness significant advancements in cast resin busbar technology, driven by a surge in demand for efficient and sustainable electrical solutions. One of the emerging trends is the integration of smart features into cast resin busbars, enabling real-time monitoring of electrical parameters. This will enhance safety and reliability while allowing for predictive maintenance, thus reducing downtime and maintenance costs.

Additionally, manufacturers are focusing on developing more environmentally friendly materials for cast resin busbars. These innovations not only improve performance but also align with the global shift towards sustainability in the electrical industry. Such materials offer enhanced thermal and mechanical properties, catering to high-performance applications in industries ranging from renewable energy to electric vehicles.

Tips: When selecting cast resin busbars for your projects, consider the long-term benefits of investing in smart technology and sustainable materials. This can lead to reduced operational costs and improved energy efficiency. Keeping abreast of the latest developments in this field will ensure that you are well-equipped to make informed decisions that align with the future of energy and electrical infrastructure.

Cast resin busbars are quickly gaining traction in the electrical distribution sector, offering several distinct advantages over traditional conductive systems. According to a recent report by Mordor Intelligence, the global market for cast resin busbars is expected to grow at a CAGR of 5% from 2023 to 2028, reflecting an increasing preference among industries for more efficient, reliable, and sustainable energy solutions. One of the primary benefits of cast resin busbars is their superior insulation properties, which eliminate the need for extensive maintenance compared to conventional metal busbars. This reduces not only the operational costs but also minimizes the risk of electrical failures due to environmental factors.

Moreover, cast resin busbars are inherently more resistant to corrosion and environmental degradation. A study published by Research and Markets indicates that over 30% of electrical failures in conventional systems arise from corrosion-related issues, which are largely mitigated by the robust properties of cast resin materials. These busbars can also operate efficiently in extreme temperature conditions, further demonstrating their reliability. Additionally, with the rising emphasis on environmental sustainability, adopting cast resin busbars contributes to greener energy practices, making them an attractive choice for future energy infrastructure developments.

| Innovation | Key Advantages | Applications | Performance Metrics |

|---|---|---|---|

| Improved Thermal Management | Lower temperature rise, enhanced efficiency | Data centers, industrial applications | Up to 30% higher thermal conductivity |

| Compact Design | Space-saving, lightweight | Renewable energy systems, commercial buildings | Reduction in installation footprint by 20% |

| Enhanced Insulation Properties | Increased electrical resistance, reduced losses | High-voltage applications, substations | Improvement in dielectric strength by 15% |

| Green Materials | Sustainable sourcing, reduced environmental impact | Eco-friendly buildings, energy-efficient solutions | 50% reduction in carbon footprint during production |

| Modular Design | Ease of installation, scalability | Industrial plants, telecommunications | Time-to-install reduced by 25% |

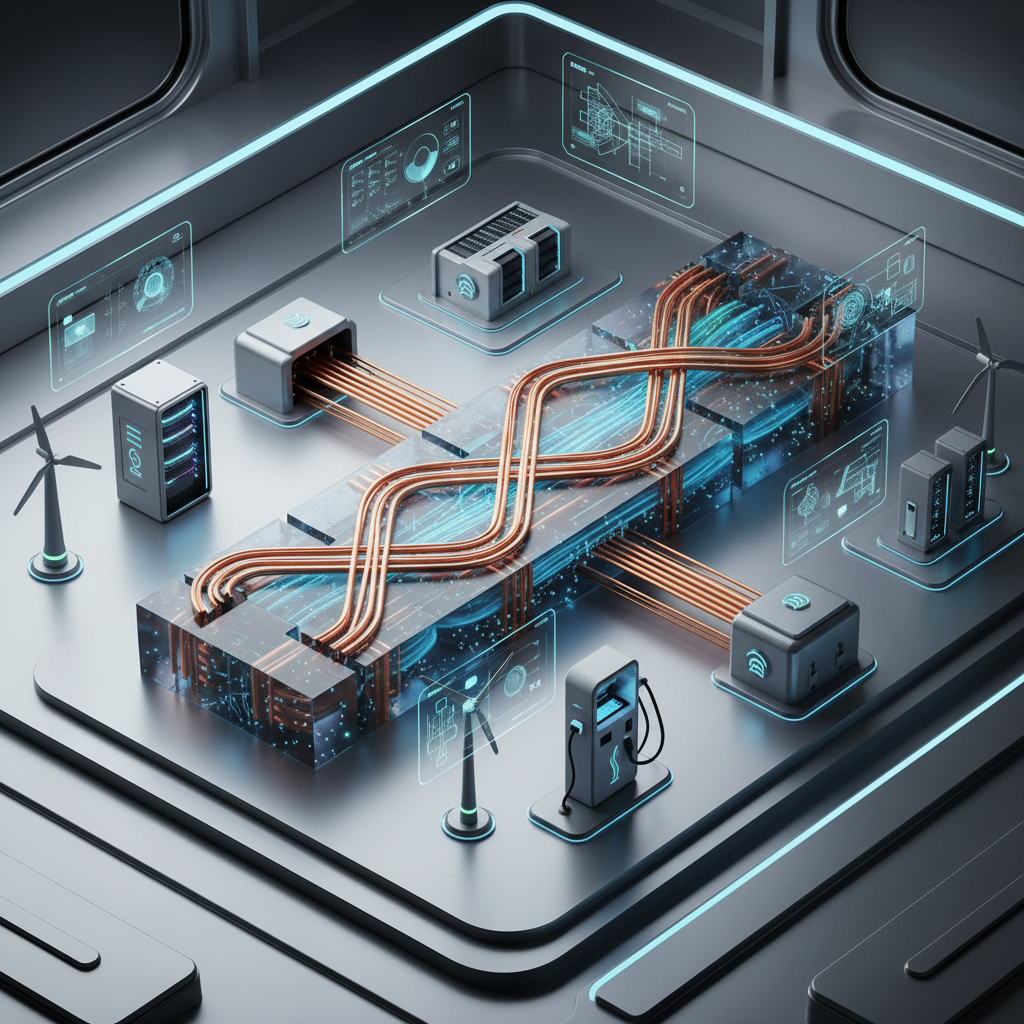

The adoption of cast resin busbars is rapidly transforming the renewable energy sector, offering innovative solutions for energy distribution and management. According to the latest report from the International Energy Agency (IEA), investments in renewable energy are projected to reach $4 trillion by 2025, highlighting the growing need for efficient and reliable distribution systems. Cast resin busbars, known for their durability and resistance to environmental factors, are emerging as a key component in enhancing the efficiency of renewable installations, such as solar farms and wind energy systems.

Tips for implementing cast resin busbars include choosing the right design based on the specific energy needs of your application. It's essential to consider the thermal management capabilities of the busbars, as well as their insulation properties, to prevent energy losses and ensure safety. Additionally, regular maintenance and monitoring can significantly extend the lifespan of these systems, making them a cost-effective choice in the long run.

As renewable energy technologies evolve, the versatility of cast resin busbars continues to be an asset. They are increasingly used in hybrid systems that integrate multiple sources of renewable energy, enabling a more resilient and sustainable energy infrastructure. The latest market analysis reveals that the global market for cast resin busbars is expected to grow at a CAGR of 7.5% from 2023 to 2028, demonstrating their vital role in the future of energy distribution.

The integration of smart grid technologies is poised to revolutionize the design and application of cast resin busbars. As energy systems evolve towards more decentralized and digital operations, the demand for reliable, efficient, and innovative busbar solutions becomes ever more critical. Smart grids facilitate real-time monitoring and data analytics, allowing for enhanced performance metrics and predictive maintenance strategies. This shift necessitates the development of cast resin busbars that not only exhibit high levels of insulation and mechanical strength but also incorporate smart sensors and communication capabilities.

Moreover, the impact of smart grids drives innovation in the design of cast resin busbars to meet the growing challenges of load variability and renewable energy integration. The busbars must now support greater flexibility and adaptability, enhancing their functionality to seamlessly connect with various energy resources, including solar and wind. This evolution emphasizes the need for lightweight yet durable materials, as well as innovations in thermal management and electromagnetic performance. As we advance toward 2025, these adaptations will ensure that cast resin busbars remain pivotal components in intelligent energy distribution systems, providing the resilience and efficiency required in a rapidly changing energy landscape.

Cast resin busbars have emerged as a pivotal innovation in electrical power distribution, particularly due to their ecological advantages. These busbars are encapsulated in a resin material that not only enhances electrical performance but also serves as a significant barrier against environmental hazards. Their design minimizes energy losses, which ultimately contributes to lower carbon footprints during operation. By reducing the need for frequent replacements and ensuring durability, cast resin busbars align with sustainability objectives in modern infrastructure.

Furthermore, the manufacturing process for cast resin busbars is increasingly utilizing recyclable materials and eco-friendly practices. This shift supports a circular economy by decreasing waste and promoting resource efficiency. The longevity of these busbars also means less frequent maintenance and repair, which in turn fosters energy conservation. The concentrated efforts in research and development emphasize reducing environmental impact while maximizing performance, making cast resin busbars a cornerstone technology for sustainable energy systems in the years to come.